Comb-shaped associative polyurethane composite modified organic silicon softener emulsion and preparation method thereof

A technology of silicone softener and associative polyurethane, which is applied in the field of comb-like associative polyurethane compound modified silicone softener emulsion and its preparation, can solve the problems of not being able to obtain a novel hand feeling style and being inseparable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] One aspect of the present invention provides a method for preparing a comb-like association type polyurethane composite modified silicone softener emulsion, said method comprising the following steps:

[0069] (1) Preparation of raw materials: The raw materials contain polymerized monomers, auxiliary agents, silicone softeners and water; wherein, the polymerized monomers include diisocyanate, hydroxyl-terminated polysiloxane, functional chain extenders and cationic chain extenders agent; auxiliary agent includes polymerization catalyst, diluent, neutralizer and emulsifier; silicone softener is amino silicone oil; water is soft water;

[0070] The diisocyanate is isophorone diisocyanate;

[0071] Hydroxyl-terminated polysiloxane is a mixture of single-ended dihydroxyalkyl polymethylsilane with a molecular weight of 6000-9000 and two-terminal dihydroxyalkyl polymethylsilane with a molecular weight of 1500-2500;

[0072] The functional chain extender is a single-ended dih...

Embodiment 1

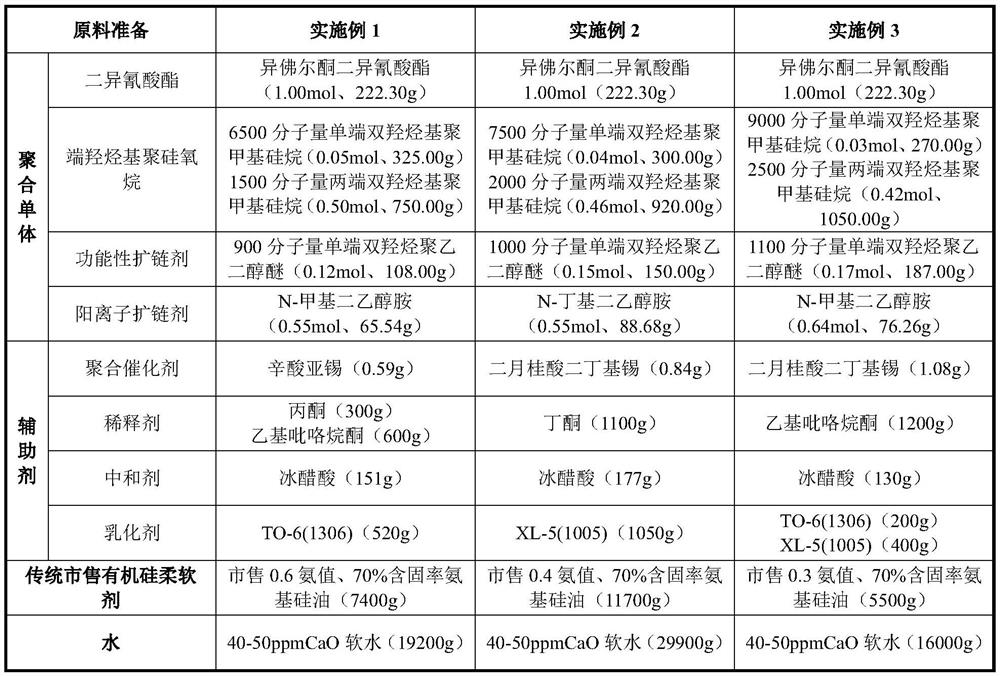

[0125] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0126] (2) Dehydration pretreatment: dehydration pretreatment of the functional chain extender under vacuum and heating conditions, and set aside;

[0127] (2.1) put the functional chain extender into the reactor;

[0128] (2.2) Heat to 102°C, treat at -0.099MPa vacuum for 80min, and set aside;

[0129] (3) Prepolymerization: Prepolymerize diisocyanate, hydroxyl-terminated polysiloxane, and polymerization catalyst to prepare a comb-like associative polyurethane composite modified silicone softener prepolymer;

[0130] (3.1) Add diisocyanate into the reactor, slowly add hydroxyl-terminated polysiloxane at 72°C within 20 minutes, and keep warm for 20 minutes;

[0131] (3.2) Add a polymerization catalyst to (3.1) and maintain the reaction at 77°C for 17.5 minutes;

[0132] (3.3) Raise the temperature to 90°C, and cool down to 80°C after holding the h...

Embodiment 2

[0145] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0146] (2) Dehydration pretreatment: dehydration pretreatment of the functional chain extender under vacuum and heating conditions, and set aside;

[0147] (2.1) put the functional chain extender into the reactor;

[0148](2.2) Heat to 102°C, treat at -0.099MPa vacuum for 75min, and set aside;

[0149] (3) Prepolymerization: Prepolymerize diisocyanate, hydroxyl-terminated polysiloxane, and polymerization catalyst to prepare a comb-like associative polyurethane composite modified silicone softener prepolymer;

[0150] (3.1) Add the diisocyanate into the reactor, slowly add the hydroxyl-terminated polysiloxane at 75°C within 15 minutes, and keep the reaction for 25 minutes;

[0151] (3.2) Add a polymerization catalyst to (3.1) and maintain the reaction at 77°C for 17 minutes;

[0152] (3.3) Raise the temperature to 90°C, and cool down to 80°C after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrophilicity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com