Multi-arm associated polyurethane composite modified organic silicon softener emulsion and preparation method thereof

A technology of silicone softener and associative polyurethane, which is applied in the field of preparation of multi-arm associative polyurethane composite modified silicone softener emulsion, can solve the problems of lack of change, simple structure, poor degree of freedom, etc., and achieve remarkable Modification effect, effect of novel style effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] One aspect of the present invention provides a method for preparing a multi-arm associative polyurethane composite modified silicone softener emulsion, the method comprising the following steps:

[0068] (1) Preparation of raw materials: The raw materials contain polymerized monomers, auxiliary agents, silicone softeners and water; wherein, the polymerized monomers include diisocyanate, hydroxyl-terminated polyether triol, hydroxyl-terminated hydrocarbon polysiloxane and hydroxyl-terminated Polyether glycol; auxiliary agent includes polymerization catalyst, diluent, neutralizer and emulsifier; silicone softener is amino silicone oil; water is soft water;

[0069] The diisocyanate is isophorone diisocyanate;

[0070] The hydroxyl-terminated polyether triol is a random copolymer of ethylene oxide and propylene oxide with a molecular weight of 2000-4000;

[0071] Hydroxyl-terminated polysiloxane is dihydroxyl-alkyl polymethylsilane with a molecular weight of 2000-4000;

...

Embodiment 1

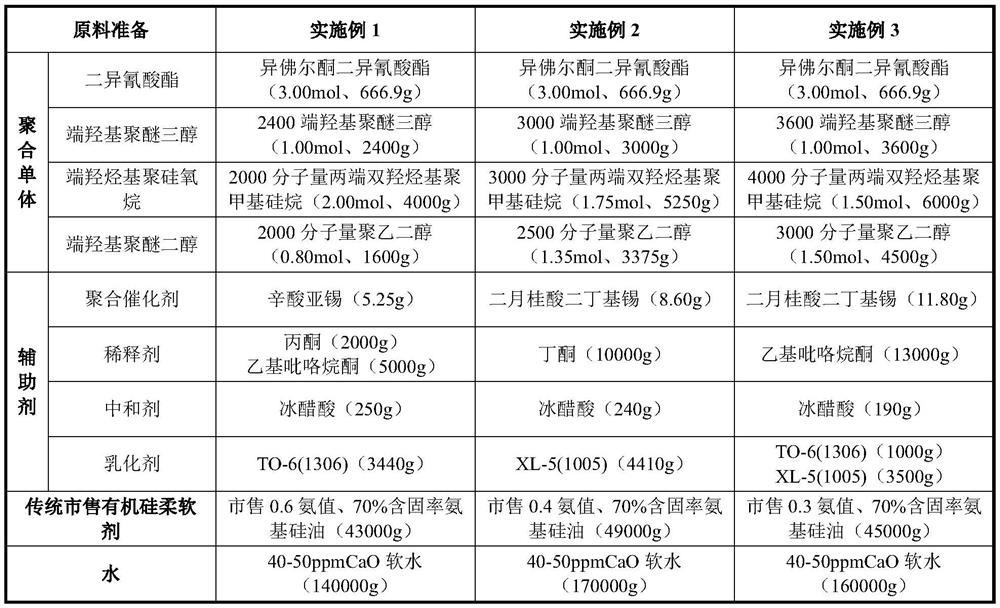

[0123] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0124] (2) Dehydration pretreatment: dehydration pretreatment of hydroxyl-terminated polyether triol and hydroxyl-terminated polyether diol under vacuum and heating conditions respectively, for subsequent use;

[0125] (2.1) Put the hydroxyl-terminated polyether triol and the hydroxyl-terminated polyether diol into different reactors respectively;

[0126] (2.2) Treat at 102°C and -0.099MPa vacuum for 77 minutes respectively, and set aside;

[0127] (3) One-time capping: carry out a one-time capping reaction on diisocyanate, hydroxyl-terminated polyether triol, part of the polymerization catalyst, and part of the diluent to prepare a multi-arm associative polyurethane composite modified silicone softener intermediate;

[0128] (3.1) Add diisocyanate into the reactor, slowly add 50% of the hydroxyl-terminated polyether triol obtained in step (2.2) at...

Embodiment 2

[0142] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0143] (2) Dehydration pretreatment: dehydration pretreatment of hydroxyl-terminated polyether triol and hydroxyl-terminated polyether diol under vacuum and heating conditions respectively, for subsequent use;

[0144] (2.1) Put the hydroxyl-terminated polyether triol and the hydroxyl-terminated polyether diol into different reactors respectively;

[0145] (2.2) Treat at 108°C and -0.098MPa vacuum for 78 minutes respectively, and set aside;

[0146] (3) One-time capping: carry out a one-time capping reaction on diisocyanate, hydroxyl-terminated polyether triol, part of the polymerization catalyst, and part of the diluent to prepare a multi-arm associative polyurethane composite modified silicone softener intermediate;

[0147] (3.1) Add diisocyanate into the reactor, slowly add 60% of the hydroxyl-terminated polyether triol obtained in step (2.2) at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com