High-strength flame-retardant heat-insulation composite door and window

A high-strength, door and window technology, applied in the field of composite doors and windows, can solve the problems of flammability, corrosion, and high maintenance costs of composite doors and windows, and achieve the effects of improving optical transparency and mechanical properties, good mechanical properties, and improving dripping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

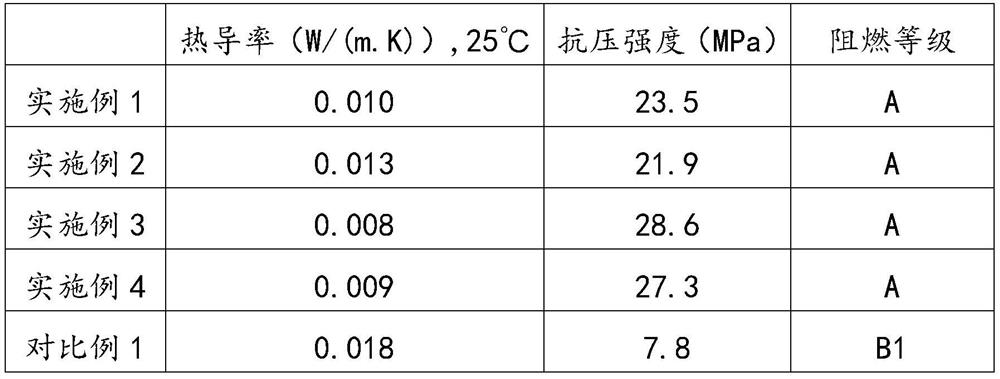

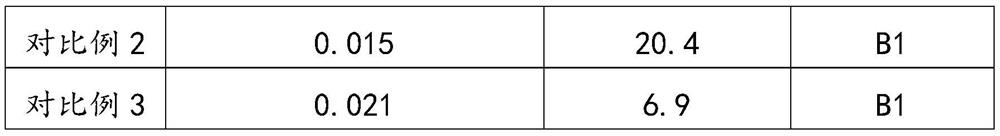

Examples

Embodiment 1

[0022] A high-strength flame-retardant and heat-insulating composite door and window in Example 1 is prepared by uniformly mixing wood-porcelain composite materials and airgel fiber mats, and then forming them by hot pressing. The process of hot press molding is as follows: according to the weight ratio, mix 100 parts of wood-ceramic composite material and 1.5 parts of airgel fiber felt evenly, put it in an oven at 100 ° C for 4 hours, then add it to the internal mixer, and set the temperature The temperature is 120-150°C, the banburying time is 30-40min, and after the banburying is completed, it is put into a hot press, and the pressure is kept at 15MPa, and the temperature is 230-250°C for hot press molding.

[0023] The above-mentioned wood-porcelain composite material is composed of the following components by weight: 60 parts of wood-plastic composite material, 30 parts of low-melting glass powder, 3 parts of dispersant, 5 parts of binder and 2 parts of defoamer. The prepa...

Embodiment 2

[0028] A high-strength flame-retardant and heat-insulating composite door and window in Example 2 is prepared by uniformly mixing wood-porcelain composite materials and airgel fiber mats, and then forming them by hot pressing. Wherein, the mass of the airgel fiber mat accounts for 3.6% of the mass of the wood-porcelain composite material. Its thermoforming process is the same as in Example 1, and the specific steps are with reference to Example 1.

[0029] The above-mentioned wood-porcelain composite material is composed of the following components by weight: 79 parts of wood-plastic composite material, 15 parts of low-melting glass powder, 3 parts of dispersant, 2 parts of binder and 1 part of defoamer. Its preparation method and implementation Same in example 1, specific steps refer to embodiment 1. Wherein, the dispersant is triethylhexyl phosphoric acid; the binder is a phenolic resin binder; the defoamer is polyoxypropylene glyceryl ether.

[0030] The above-mentioned w...

Embodiment 3

[0033] A high-strength flame-retardant and heat-insulating composite door and window in Example 3 is prepared by uniformly mixing wood-porcelain composite materials and airgel fiber mats, and then forming them by hot pressing. Wherein, the mass of the airgel fiber mat accounts for 2% of the mass of the wood-porcelain composite material. Its thermoforming process is the same as in Example 1, and the specific steps are with reference to Example 1.

[0034] The above-mentioned wood-porcelain composite material is composed of the following components by weight: 70 parts of wood-plastic composite material, 20 parts of low-melting point glass powder, 4 parts of dispersant, 3 parts of binder and 3 parts of defoaming agent. Its preparation method and implementation Same in example 1, specific steps refer to embodiment 1. Wherein, the dispersant is polyacrylamide; the binder is acrylic binder; the defoamer is polydimethylsiloxane.

[0035] The above-mentioned wood-plastic composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com