Touch recording instrument of powder spraying type pile machine

A recorder and powder-spraying technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of inconvenient configuration and inability to control the length of the pile body, and achieve perfect equipment design defects, safe and reliable engineering quality, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The powder-spraying pile driver touch recorder of the present invention comprises a first touch-sensitive sheet, a second touch-sensitive sheet, and a recorder display.

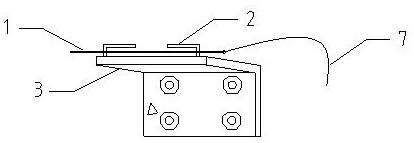

[0028] see now figure 1 , figure 1 It is a schematic structural diagram of the first touch-sensitive sheet according to an embodiment of the present invention. As shown in the figure, the first touch-sensitive sheet 1 enters the first touch-sensitive sheet slot 2 through the first touch-sensitive sheet support 3 .

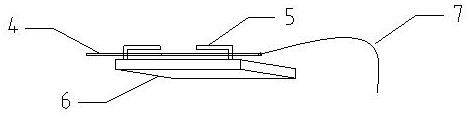

[0029] figure 2 It is a schematic structural diagram of the second touch-sensitive sheet according to the embodiment of the present invention. The second touch-sensitive sheet 4 enters the second touch-sensitive sheet slot 5 through the second touch-sensitive sheet support 6;

[0030] The recorder display 11 is fixed on the platform 8 of the powder-spraying type pile driver, near the operator's platform that is convenient for operator's observation.

[0031] Figure 4 It is a schemat...

Embodiment 2

[0034] The installation method of the powder-spraying pile driver touch recorder of the present invention:

[0035] First, make the touch sensor bracket, touch sensor card slot and instrument display fixing frame in advance before installation. The material of the touch sensor 1 / 2 bracket is 5mm thick steel plate and angle steel; the material of the card slot is 1mm thick iron sheet, and the card slot It is connected with the steel plate and angle steel by spot welding, and is used to fix the touch sensor piece 1 / 2; the instrument display fixing frame is a triangular bracket made of steel bars and circular plates.

[0036] Then the support of the touch sensor sheet 1 is fixed on the outer frame of the pile driver with a U-shaped bolt rod (fixed position: the drill bit of the pile driver is landed in advance, the highest point of the drill bit is measured downward, and the pile length L is designed). The support of the touch sensor sheet 2 is welded to the highest point of the ...

Embodiment 3

[0039] The method of using the powder-spraying pile driver touch recorder of the present invention:

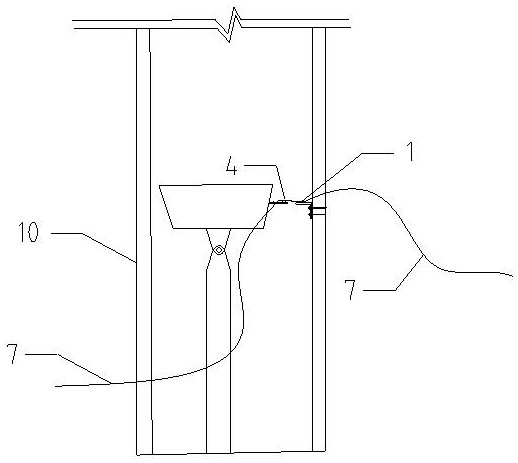

[0040] After the first touch sensor sheet, the second touch sensor sheet, and the recorder display are respectively installed through the bracket, the piling drill pipe is rotated down each time, and the touch sensor sheet 1 fixed on the bracket and the top of the drill pipe when reaching the designed length The touch sensing sheets 2 touch each other, and at the same time, the number of collisions is sensed by the sensor, and data records are formed on the instrument display.

[0041] The present invention has substantive features and significant technical progress. The powder-spraying type pile driver touch recorder of the present invention is based on the traditional pile driver. Touch sensing piece 1, touch sensing piece 2 is set on the top of the drill pipe; during the operation of the pile driver, the drill pipe rotates downward to form a hole, and drills down to the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com