Inspection device

A technology for inspection devices and inspection objects, which is applied in the direction of measuring devices, instruments, fluid resistance measurement, etc., and can solve problems such as packaging, transportation methods, and detection difficulties that cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

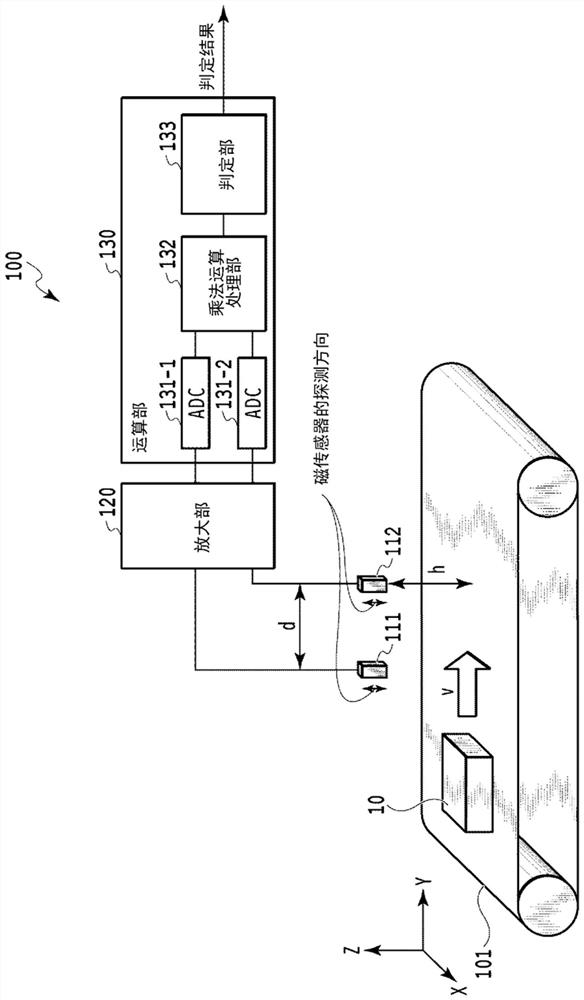

[0055] exist figure 1 In , the configuration of the inspection device according to the first embodiment of the present invention is shown. The inspection apparatus 100 is provided with: a conveyance path 101, which conveys the object 10 to be inspected at a moving speed v; Detection; Amplifying section 120, which amplifies the detection signal of the first magnetic detector 111 and the detection signal of the second magnetic detector 112 respectively; The signal obtained by the delay is multiplied by the detection signal of the second magnetic detector 112 .

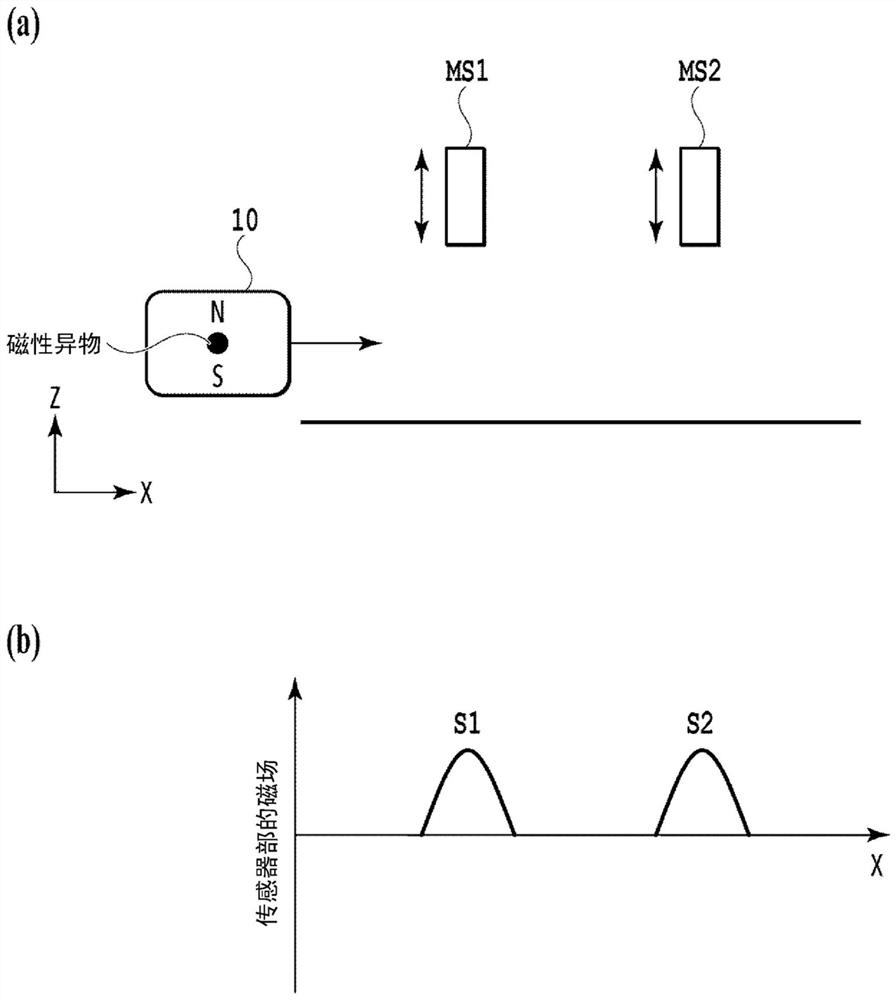

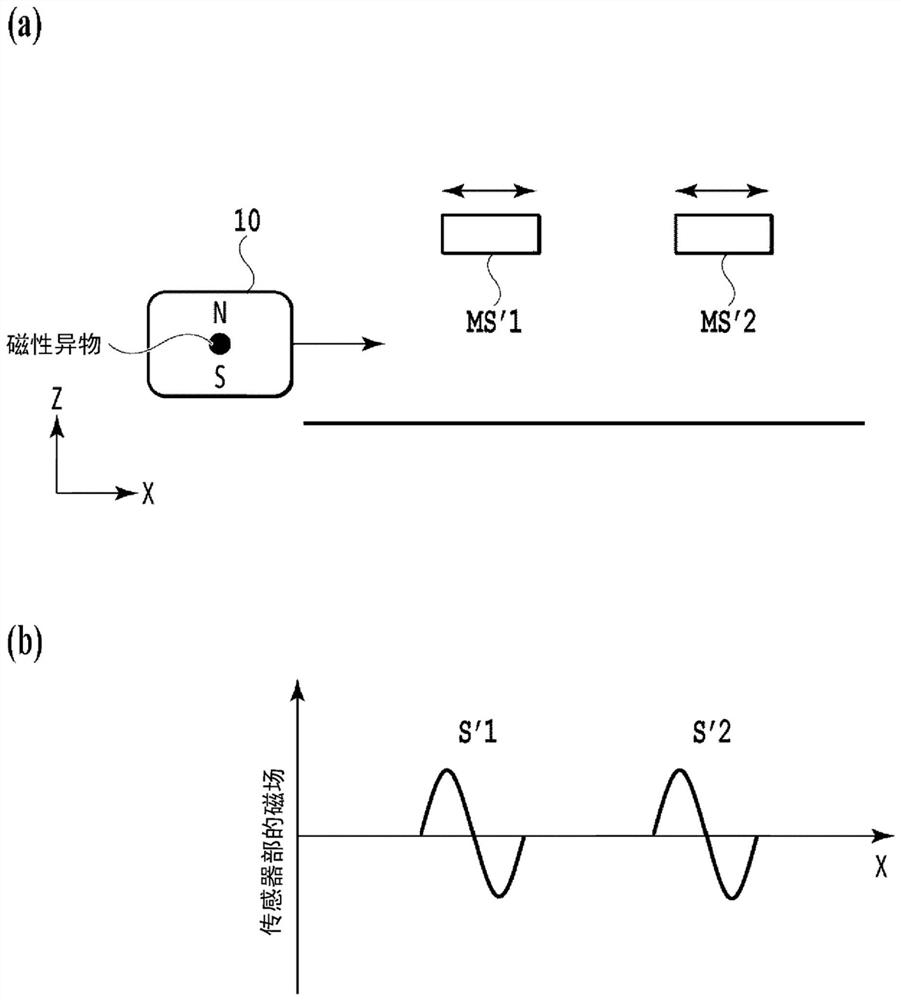

[0056] exist figure 1 In the shown configuration, for the sake of simplicity of description, each of the first magnetic detector 111 and the second magnetic detector 112 has one magnetic sensor, and these two sensors are a pair of sensors. A magnetic sensor MS1 as the first magnetic detector 111 having a magnetic field detection direction perpendicular to the conveying surface is disposed at a height h from the conv...

no. 2 approach

[0087] exist Figure 9 In , the configuration of the inspection device according to the second embodiment of the present invention is shown. In the second embodiment, a configuration is shown in which the detection accuracy of detecting magnetic foreign objects in the width direction of the conveyance path 101 and in the vertical direction of the conveyance path 101 is improved. The inspection apparatus 200 is provided with: a conveyance path 101, which conveys the object 10 to be inspected at a moving speed v; Detection; Amplifying section 220, which amplifies the detection signal of the first magnetic detector 211 and the detection signal of the second magnetic detector 212 respectively; The signal obtained by the delay is multiplied by the detection signal of the second magnetic detector 212 .

[0088] In the first embodiment, the structure in which the first magnetic detector 111 and the second magnetic sensor 112 each have one magnetic sensor was described as an example...

no. 3 approach

[0095] 3rd Embodiment describes the structure of the inspection apparatus which makes the detection accuracy of the magnetic foreign object of 1st Embodiment and 2nd Embodiment more accurate. Note that descriptions of items common to the first embodiment and the second embodiment are omitted.

[0096] In the third embodiment, the arithmetic processing units 130 , 230 of the inspection devices 100 , 200 further include means for averaging detection signals and periodic noise removal means. These means can be used to perform averaging processing on the detection signals of the first magnetic detectors 111, 211 and the second magnetic detectors 112, 212, respectively. The averaging processing may also be moving average, summed average, or the like. By performing averaging processing, noise can be rounded, and the S / N ratio of multiplication processing can be improved. In addition, averaging processing may be performed on the multiplication results.

[0097] The transport path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com