Automatic feeding intelligent welding production equipment for stair step corner protector for buildings

A technology for construction and material feeding, which is applied in the direction of stairs, buildings, building structures, etc., and can solve the problems of large error of the auxiliary rod 92, heavy workload, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

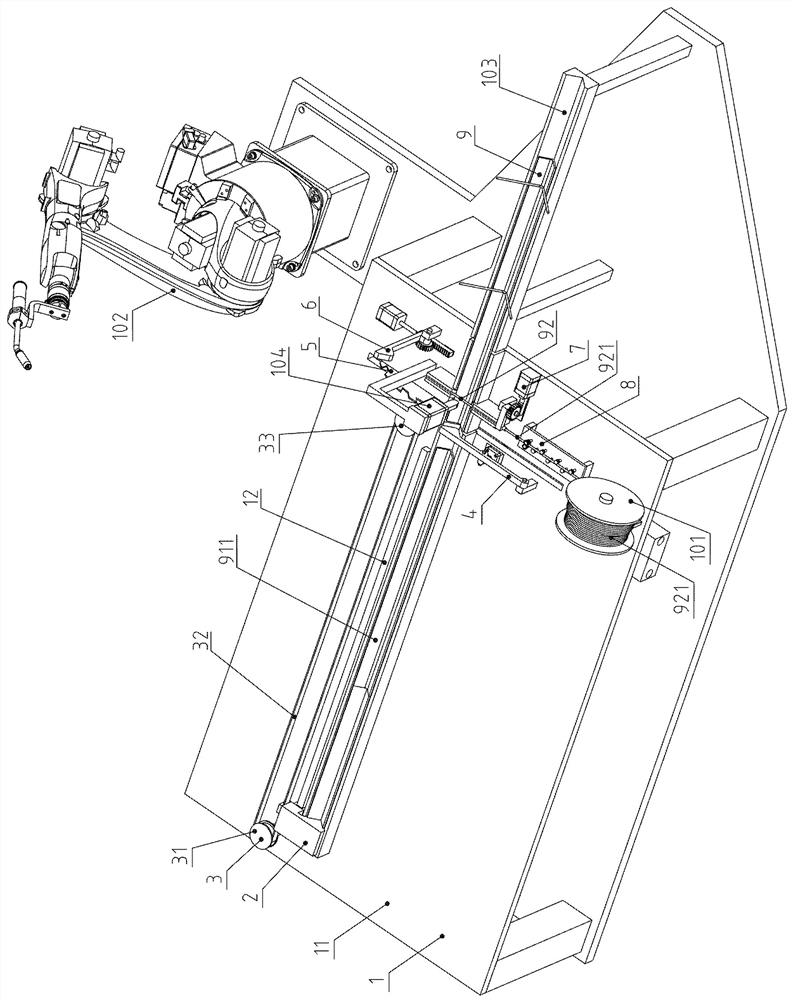

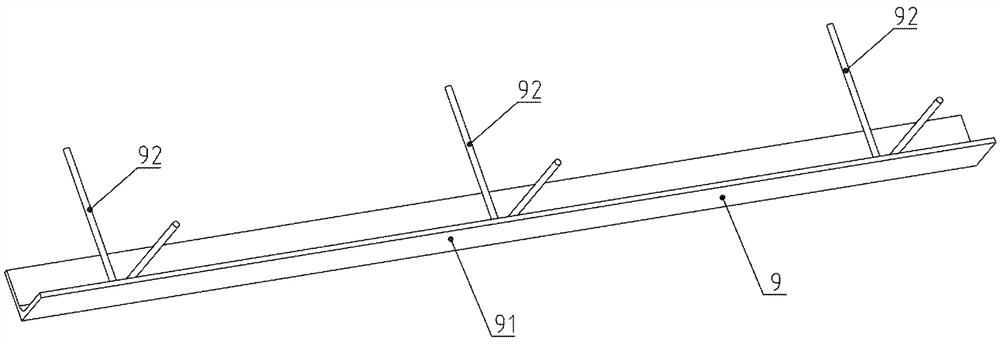

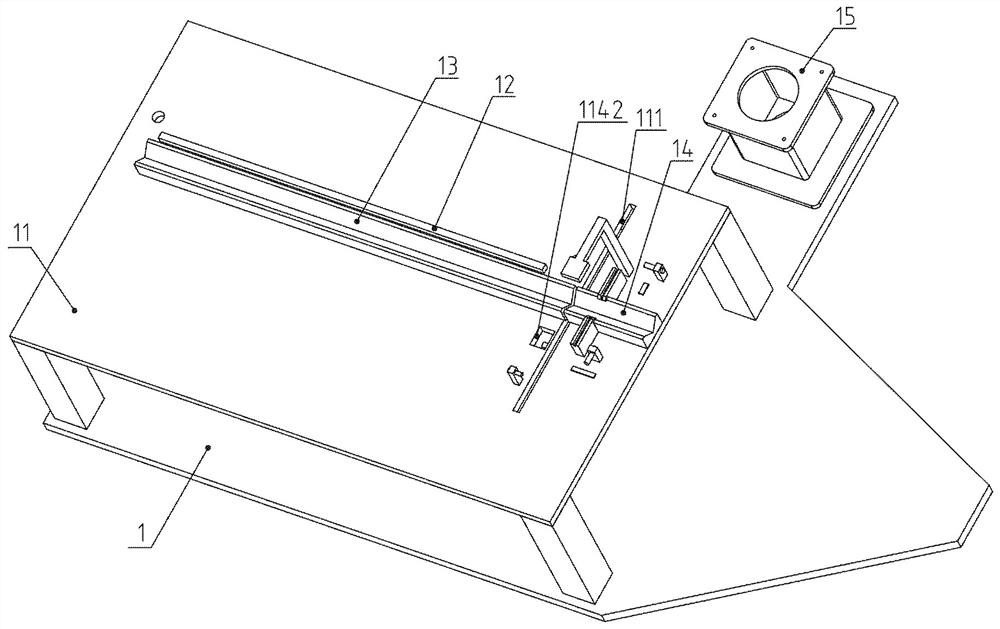

[0062] Example: see Figure 1 to Figure 12 .

[0063] An automatic feeding intelligent welding production equipment for building stair step corner protectors, including a frame 1, a synchronous belt assembly 3, a sawing assembly 5, a driving roller assembly 8, and a welding robot 102; the welding robot 102 is fixedly connected to the frame 1;

[0064] The frame 1 includes a workbench panel 11, and the workbench panel 11 is arranged horizontally; the workbench panel 11 is provided with a vertically transparent circular saw avoidance seam 111; the length direction of the circular saw avoidance seam 111 is the left-right direction;

[0065] The sawing assembly 5 comprises an electric cylinder 51, a saw motor 52 and a circular saw blade 53; the electric cylinder 51 is a band guide rod type electric cylinder, and the electric cylinder 51 comprises an electric cylinder block 511 and an electric cylinder push rod 512; the electric cylinder block 511 Fixedly connected with the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com