Graphene oxide aerogel fiber fabric as well as preparation method and application thereof

A graphene aerogel and graphene gel fiber technology, applied in chemical instruments and methods, separation methods, chemical characteristics of fibers, etc., can solve the complex electrospinning preparation process, the material is subject to its own stability, and cannot be used for long-term use. and other problems, to achieve excellent PM2.5 capture performance, good application prospects, and the effect of improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method steps of graphene oxide airgel fiber fabric in the present embodiment are as follows:

[0025] (1) Disperse 24 mg of graphene oxide into 4 mL of deionized water, oscillate and mix for 2 min, and sonicate for 4 min to obtain a well-dispersed graphene oxide solution with a concentration of 6 mg / mL;

[0026] (2) At a rate of 10 μL / min, inject the graphene oxide solution obtained in step 1 into a rotating coagulation bath at 5 r / min through a spinning head with a diameter of 50 μm (in this example, the mass fraction of the rotating coagulation bath is 1% CaCl 2 solution, the solvent in the solution is a mixture of water and ethanol with a volume ratio of 1:9), solidified for 1 s and then washed with deionized water to obtain graphene oxide gel fibers;

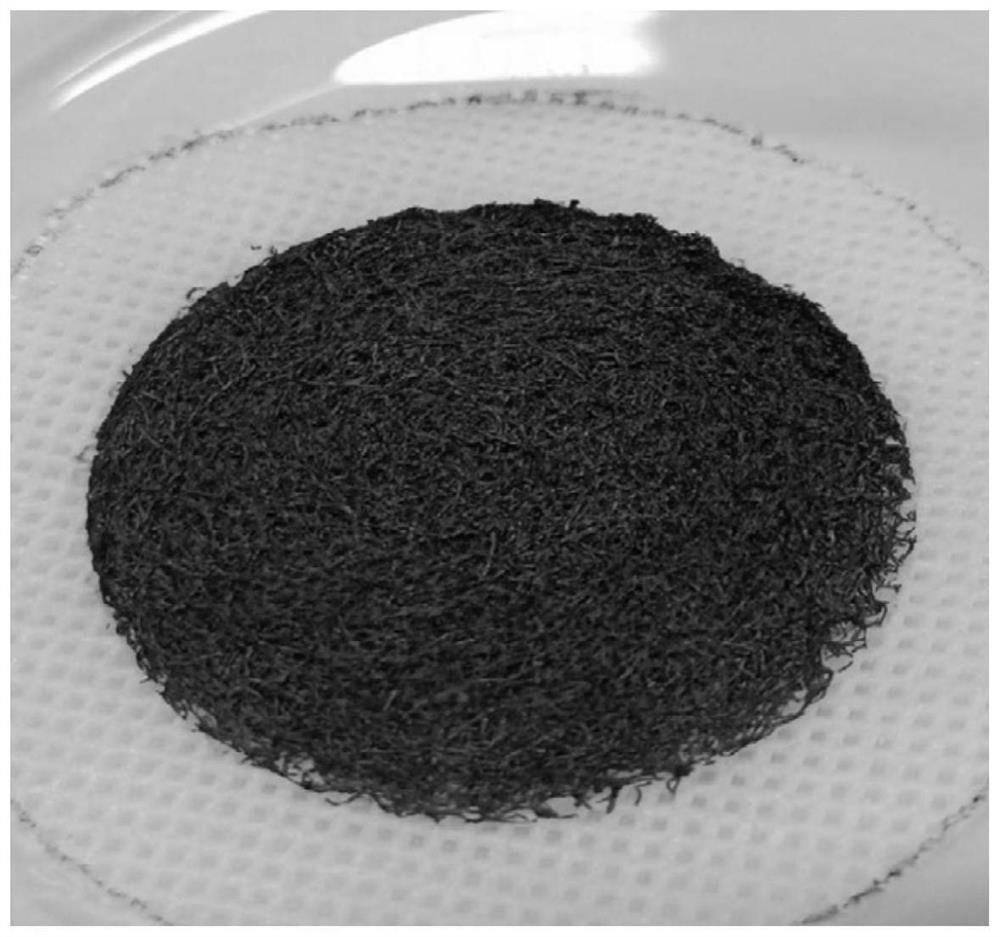

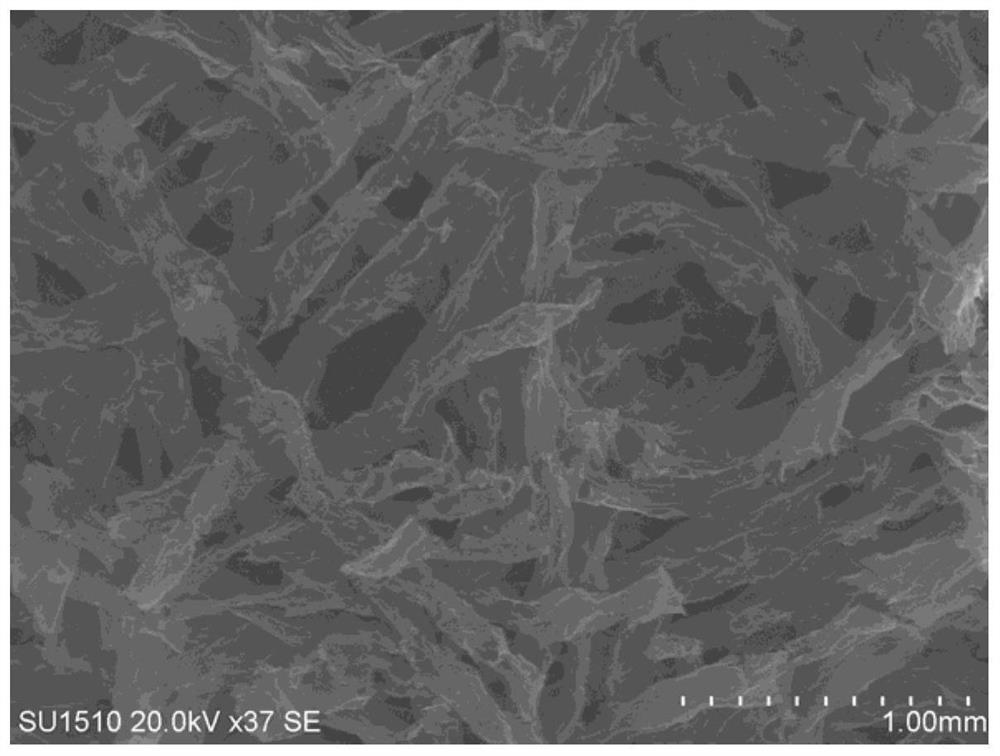

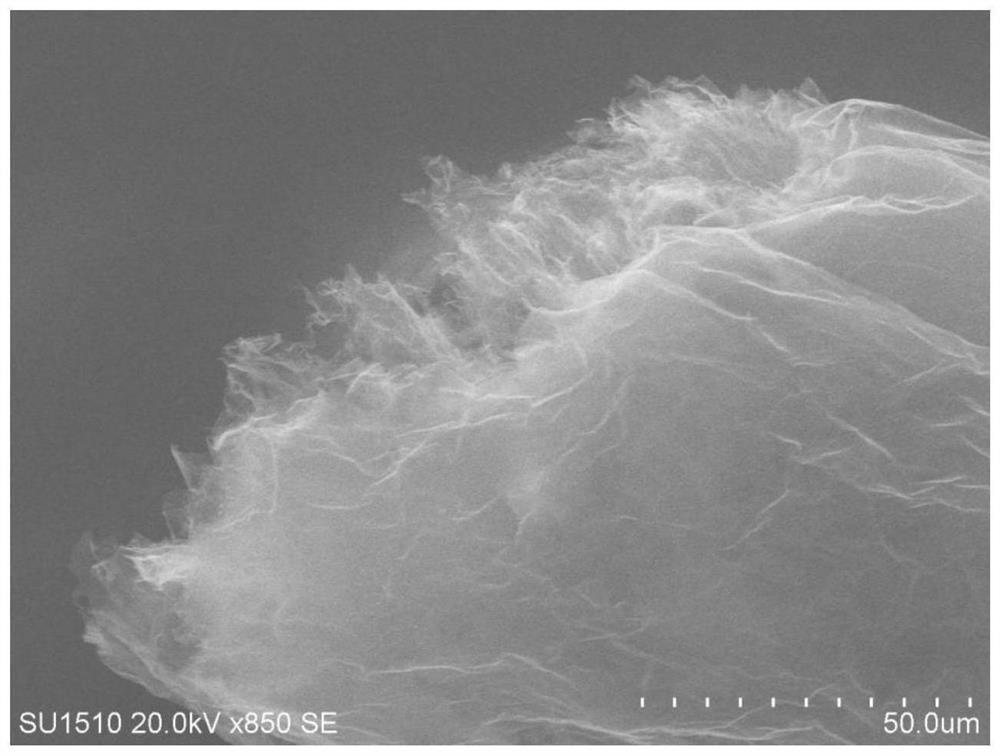

[0027] (3) The gel fibers obtained in step (2) were taken, assembled by suction filtration to obtain gel fiber fabrics, and then freeze-dried for 24 h to obtain graphene oxide airgel fiber fabrics.

...

Embodiment 2

[0032] The preparation method steps of graphene oxide airgel fiber fabric in the present embodiment are as follows:

[0033] (1) Disperse 24 mg of graphene oxide into a mixture of 3 mL of deionized water and 3 mL of ethanol, oscillate and mix for 5 min, and sonicate for 10 min to obtain a well-dispersed graphene oxide solution with a concentration of 4 mg / mL ;

[0034] (2) At a rate of 50 μL / min, inject the graphene oxide solution obtained in step (1) into a rotary coagulation bath with a rotation speed of 15 r / min through a spinning head with a diameter of 100 μm (in this example, the rotary coagulation The bath is CaCl with a mass fraction of 5% 2 solution, the solvent in the solution is a mixture of water and ethanol with a volume ratio of 1:3), solidified for 50 s and washed with deionized water to obtain graphene oxide gel fibers;

[0035] (3) The gel fibers obtained in step (2) were taken, assembled by suction filtration to obtain gel fiber fabrics, and then freeze-dri...

Embodiment 3

[0039] The preparation method steps of graphene oxide airgel fiber fabric in the present embodiment are as follows:

[0040] (1) Disperse 4 mg of graphene oxide into 2 mL of deionized water, oscillate and mix for 5 min, and sonicate for 10 min to obtain a well-dispersed graphene oxide solution with a concentration of 2 mg / mL;

[0041] (2) At a rate of 150 μL / min, inject the graphene oxide solution obtained in step (1) into a rotary coagulation bath with a rotation speed of 20 r / min through a spinning head with a diameter of 250 μm (in this example, the rotary coagulation The bath is CaCl with a mass fraction of 25% 2 solution, the solvent in the solution is a mixture of water and ethanol with a volume ratio of 9:1), solidified for 150 s and washed with deionized water to obtain graphene oxide gel fibers;

[0042] (3) The graphene oxide gel fiber obtained in step (2) was taken, assembled by suction filtration to obtain a gel fiber fabric, and then freeze-dried for 48 h to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com