Coupling structure of single shear wall column and reinforcing method of single shear wall column

A coupling structure and shear wall technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of complex design and construction, complex seismic design of coupling beams, small span-to-height ratio of coupling beams, etc. Simple, easy to repair and replace, extended use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

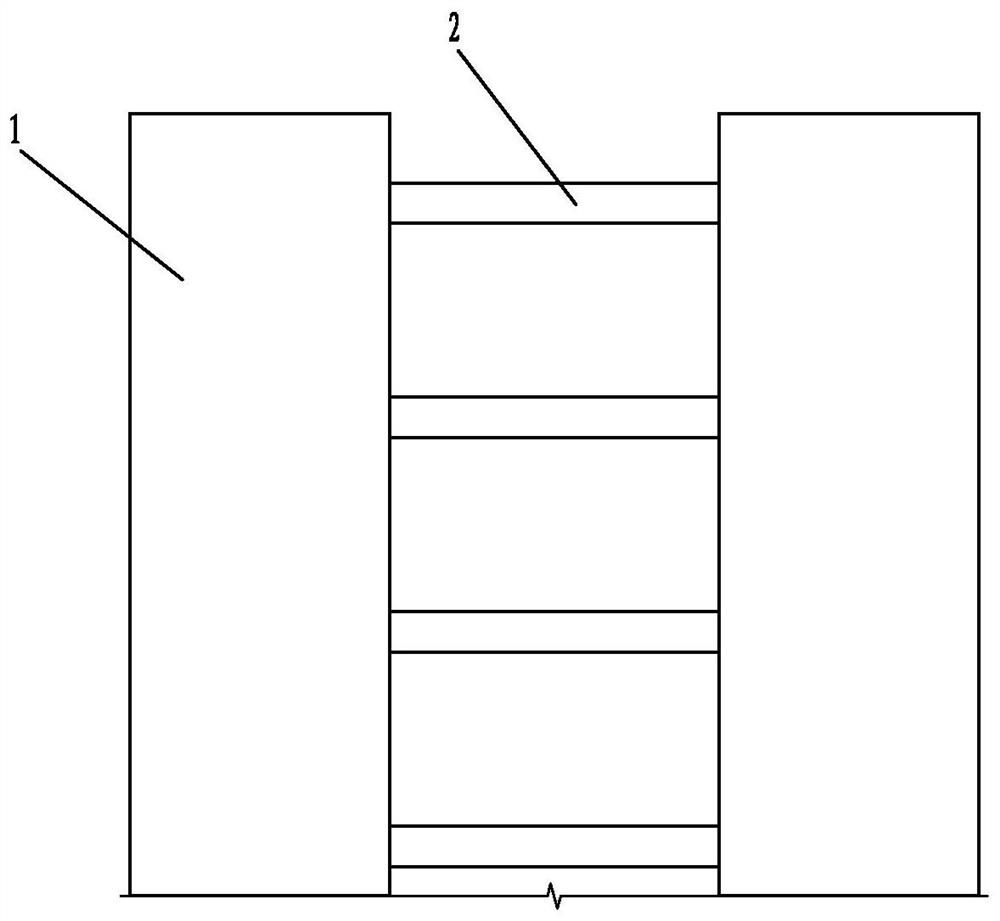

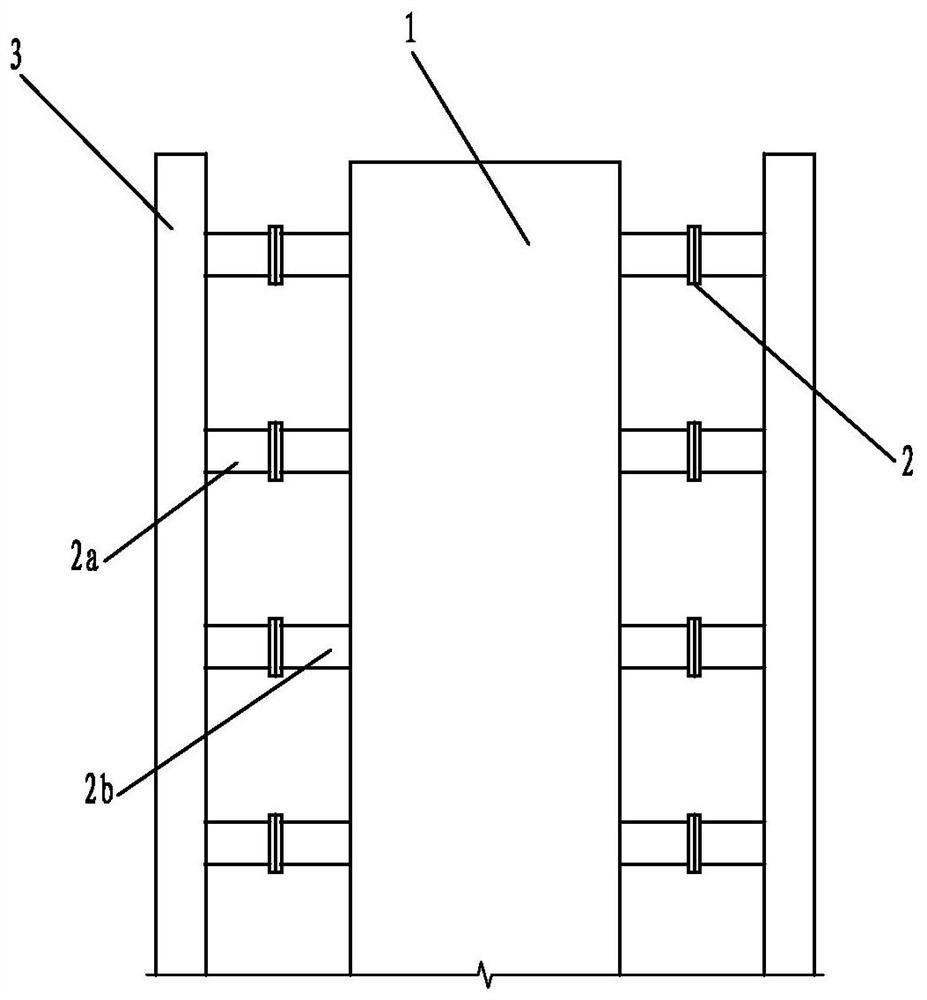

[0020] Such as figure 1 with figure 2 As shown, the present invention discloses a coupling structure of a single-piece shear wall and a method for strengthening a single-piece shear wall, wherein the coupling structure of a single-piece shear wall includes a single-piece shear wall, which is characterized in that : Both sides of the single-piece shear wall are provided with strengthening units; wherein: each of the strengthening units includes a vertically arranged steel column 3 and at least two horizontally arranged connecting beams 2, One end of the coupling beam 2 is fixedly connected to the single-piece shear wall limb 1, and the other end is fixedly connected to the steel column 3. All the coupling beams 2 are distributed vertically, and the single-piece shear wall limb 1, steel column 3 and all The connecting beams 2 are all located on the same cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com