Backlight module with blue light blocking and reflecting film and liquid crystal display panel

A backlight module and reflective film technology, applied in optics, instruments, optical components, etc., can solve the problems of retinal pigment epithelial cell decline, light-sensitive cells lack of nutrients, and no protective measures, etc., to solve the damage of blue light to human eyes , Increase the ratio of red light and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

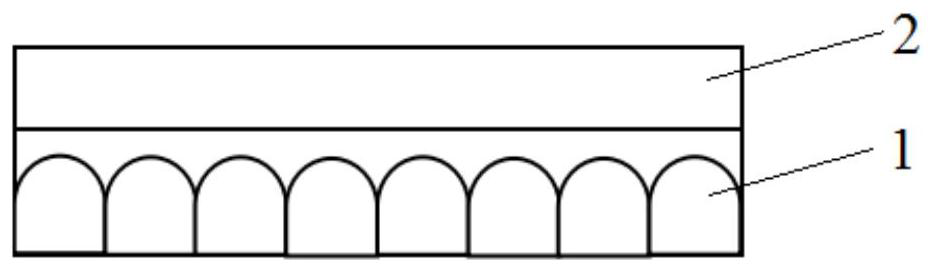

[0025] A blue light blocking reflective film such as figure 1 As shown, it includes a reflective film substrate 1 with a thickness of 20 μm, and a layer of anti-blue light coating 2 with a thickness of 100 μm is fixed on the upper surface of the reflective film substrate 1 by coating.

[0026] Among them, the material of the anti-blue light coating 2 is made of blue light filtering dye and transparent resin, the weight percentage of the blue light filtering dye is 1%; the blue light filtering dye is azo complex dye (BASF), and the transparent resin is acrylic acid Resin-like; The anti-blue light coating is prepared by dispersing the filter blue light dye in the transparent resin by high-speed shearing method, and then fixed on the surface of the emission film substrate by coating method.

[0027] Use the above blue light blocking reflective film for the backlight module.

Embodiment 2

[0029] A blue light blocking reflective film such as figure 1 As shown, it includes a reflective film substrate 1 with a thickness of 100 μm, and a layer of anti-blue light coating 2 with a thickness of 50 μm is fixed on the upper surface of the reflective film substrate 1 by coating.

[0030] Among them, the material of the anti-blue light coating 2 is made of a blue light filtering dye and a transparent resin, and the weight percentage of the blue light filtering dye is 10%; the blue light filtering dye is a ketimide dye, and the transparent resin is a polyurethane resin; The preparation of the blue light coating is to disperse the filter blue light dye in the transparent resin by a high-speed shearing method, and then fix it on the surface of the emission film substrate by a coating method.

[0031] Use the above blue light blocking reflective film for the backlight module.

Embodiment 3

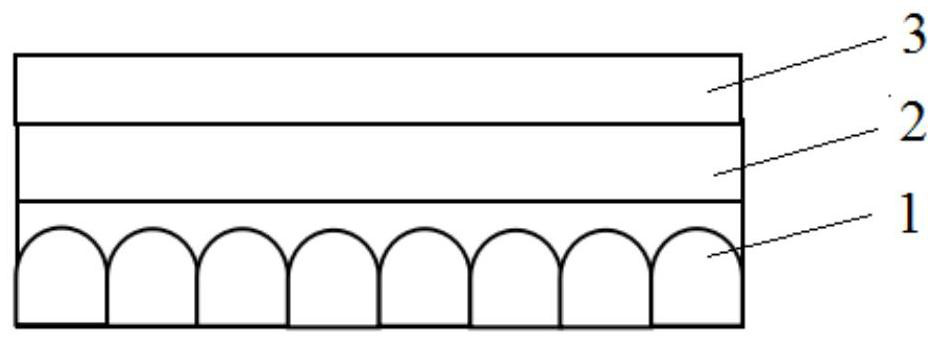

[0033] A blue light blocking reflective film such as figure 2 As shown, it includes a reflective film substrate 1 with a thickness of 200 μm. On the upper surface of the reflective film substrate 1, a layer of first anti-blue light coating 2 is first fixed by coating, and its thickness is 20 μm. A layer of second anti-blue light coating 3 is fixed on the blue light coating, and its thickness is 0.1 μm.

[0034] Among them, the material of the first anti-blue light coating 2 is made of blue light filtering dye and transparent resin, the weight percentage of the blue light filtering dye is 10%; the blue light filtering dye is azo-methine dye, and the transparent resin is epoxy Resin; the preparation of the first anti-blue light coating 2 is to disperse the filter blue light dye in the transparent resin by high-speed shearing method, and then fix it on the surface of the emissive film substrate by coating method.

[0035] The material of the anti-blue light coating 3 is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com