Device and method for regulating and controlling ladle bottom argon blowing flow

A technology for bottom blowing argon gas and ladle is applied in the field of devices for regulating the flow rate of the bottom blowing gas in the ladle, and the device field for regulating the flow rate of the bottom blowing argon gas in the ladle, which can solve the problem that the control precision of the bottom blowing argon gas flow in the ladle is low and the labor intensity of the operators is high. , the bottom blowing effect fluctuates greatly, etc., to achieve the effect of reducing labor intensity, reducing gas consumption, and reducing the cost of molten steel refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will be further described in conjunction with specific embodiments of the present invention. In the examples, the volume of the ladle is 150 tons.

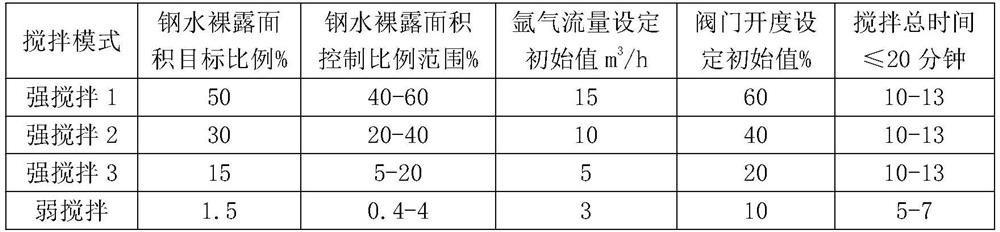

[0035] A method for regulating the flow rate of argon flow at the bottom of a ladle, comprising the following steps:

[0036] 1) Fixedly install the visual sensor above the ladle;

[0037] 2) Manipulate the visual sensor to detect the steel slag on the surface of the ladle and the exposed molten steel in the ladle;

[0038] 3) Manipulating the visual sensor to transmit the detected image data of steel slag on the surface of the ladle and exposed molten steel in the ladle to the image processing unit;

[0039] 4) Manipulate the image processing unit to process the received image data from the visual sensor, and the image processing unit processes the received image data of steel slag on the surface of the ladle and exposed molten steel in the ladle to identify molten steel, steel slag and steel ladle in the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com