Preparation method of walnut milk with high peptide content

A technology for walnut milk and content, which is applied in the field of vegetable protein processing of oil plants, can solve the problems of high product price and high processing cost, and achieve the effects of low cost, improved water solubility and reduced use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of walnut milk with high peptide content, comprising the steps of:

[0035] (1) 100g of walnuts were soaked in water at 4°C for 10 hours, and the coats were removed to obtain the coat-free walnut kernels;

[0036] (2) After cleaning the uncoated walnut kernels, add water to make the total mass 600g, grind for 2min, filter to obtain walnut pulp I and walnut residue I; add 400g water to walnut residue I, grind for 30s, filter to obtain walnut pulp II and walnut residue II; Walnut pulp I and II merge to obtain walnut pulp III (950g);

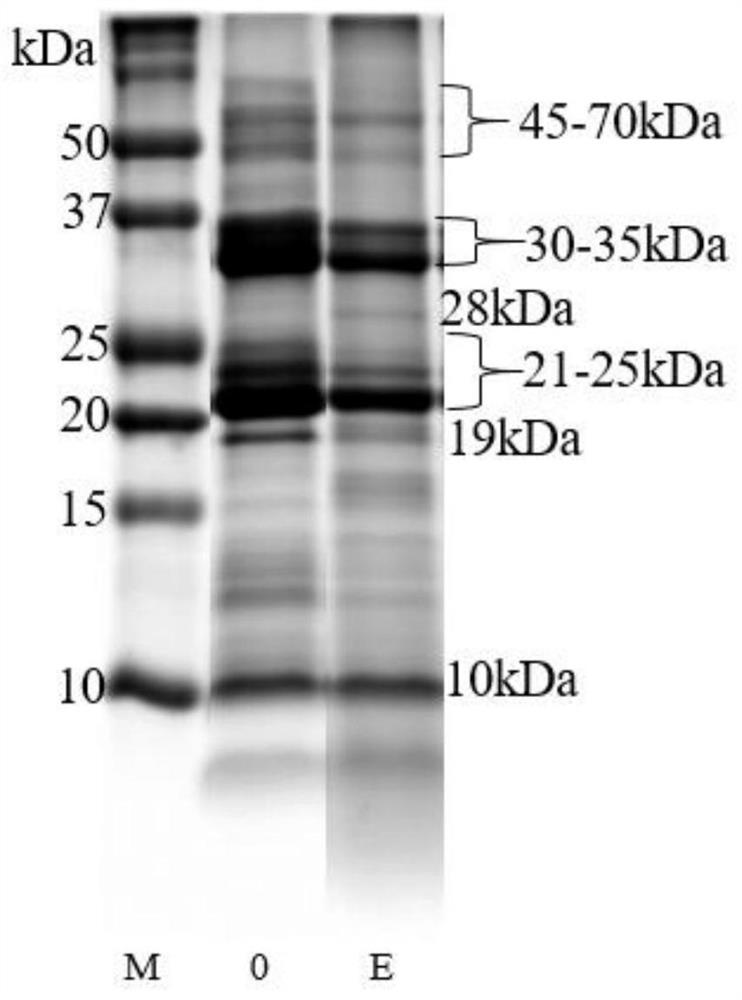

[0037] (3) Walnut pulp III is centrifuged (4000rpm, 15min), collects light phase (71g, solid content 68%), middle phase (852g) and heavy phase (about 21g); By analysis, light phase solid and protein Contents were 81.18% and 0.63% (w / w), mesophase solids and protein content were 1.47% and 0.38%, heavy phase solids and protein content were 49.27% and 41.86%; light phase, mesophase and heavy phase The protein in walnut ...

Embodiment 2

[0045] A preparation method of walnut milk with high peptide content, comprising the steps of:

[0046] (1) Soak 50g of walnuts at room temperature for 4 hours, remove the coat, and remove the coat of walnut kernels;

[0047] (2) After cleaning the uncoated walnut kernels, add water to make the total mass 300g, grind for 1.5min, filter to obtain walnut pulp I and walnut residue I; add 200g water to walnut residue I, grind for 0.5min, filter to obtain walnut pulp II and Walnut pulp II; Walnut pulp I and II merge to obtain walnut pulp III;

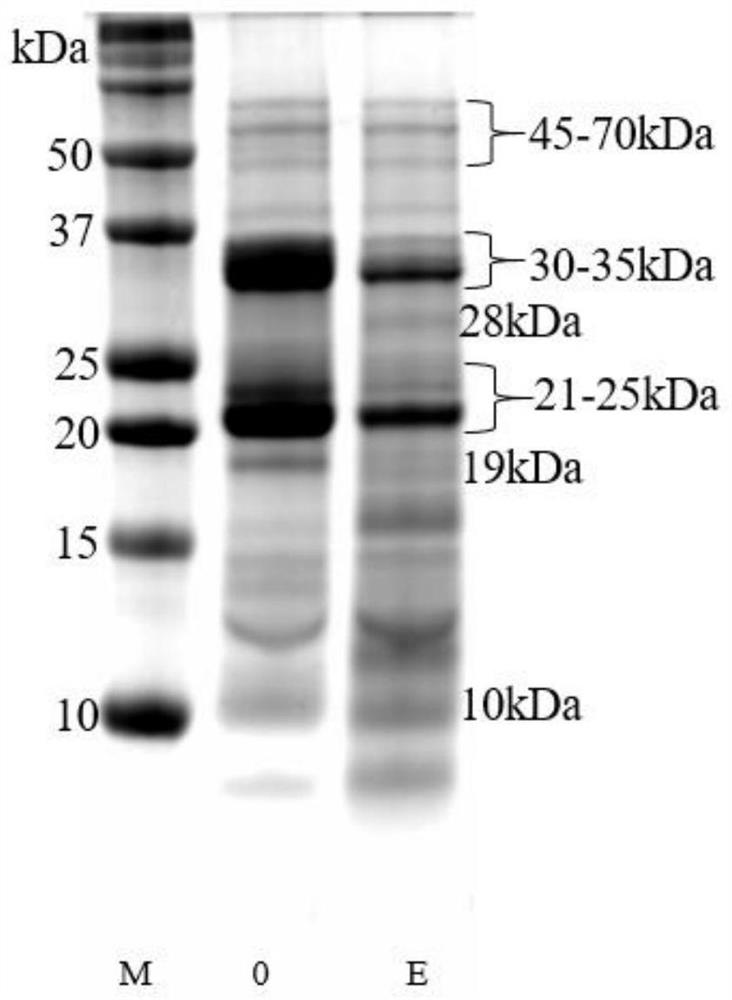

[0048] (3) Add 3% sucrose and 3% glucose to the walnut pulp III, add lactic acid bacteria according to the addition amount of 86mg / 1000g feed liquid, carry out fermentation (42°C, 9h), take 1mL feed liquid for Tricine-SDS-PAGE analysis ;

[0049] (3) Add 5‰ pectin, homogenize at 20 MPa for 5 minutes, and sterilize at high temperature (135°C, 5s) to obtain full-fat peptide-containing walnut milk.

[0050] The protein content of the beverag...

Embodiment 3

[0053] A preparation method of walnut milk with high peptide content, comprising the steps of:

[0054] (1) 100g of walnuts were soaked in water at 4°C for 10 hours, and the coats were removed to obtain the coat-free walnut kernels;

[0055] (2) After cleaning the uncoated walnut kernels, add water to make the total mass 500g, grind for 2min, filter to obtain walnut pulp I and walnut residue I; add 300g water to walnut residue I, grind for 0.5min, filter to obtain walnut pulp II and walnut Slag II; add 200g of water to walnut pulp II to obtain walnut pulp III and walnut pulp III; combine walnut pulp I, walnut pulp II and walnut pulp III to obtain walnut pulp IV;

[0056] (3) walnut pulp IV is centrifuged (5000rpm, 10min) to obtain light phase, intermediate phase and heavy phase;

[0057] (4) Mix the heavy phase and the intermediate phase evenly to obtain the walnut protein system;

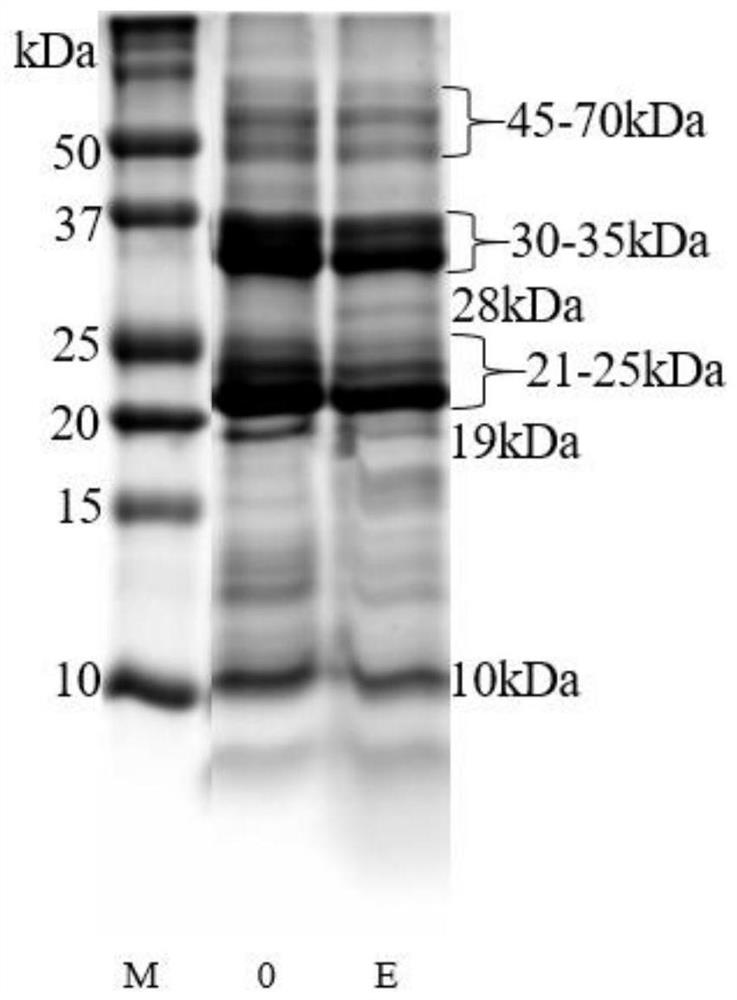

[0058] (5) Add 3% sucrose and 3% glucose, add lactic acid bacteria according to the addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com