Dragon fruit peel edible film and preparation method thereof and application of dragon fruit peel edible film

A technology for pitaya peel and peel, which is applied in the field of pitaya peel edible film and preparation thereof, can solve the problems of complex preparation process, complicated extraction, limited extraction efficiency and the like, and achieves the effects of bright appearance and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

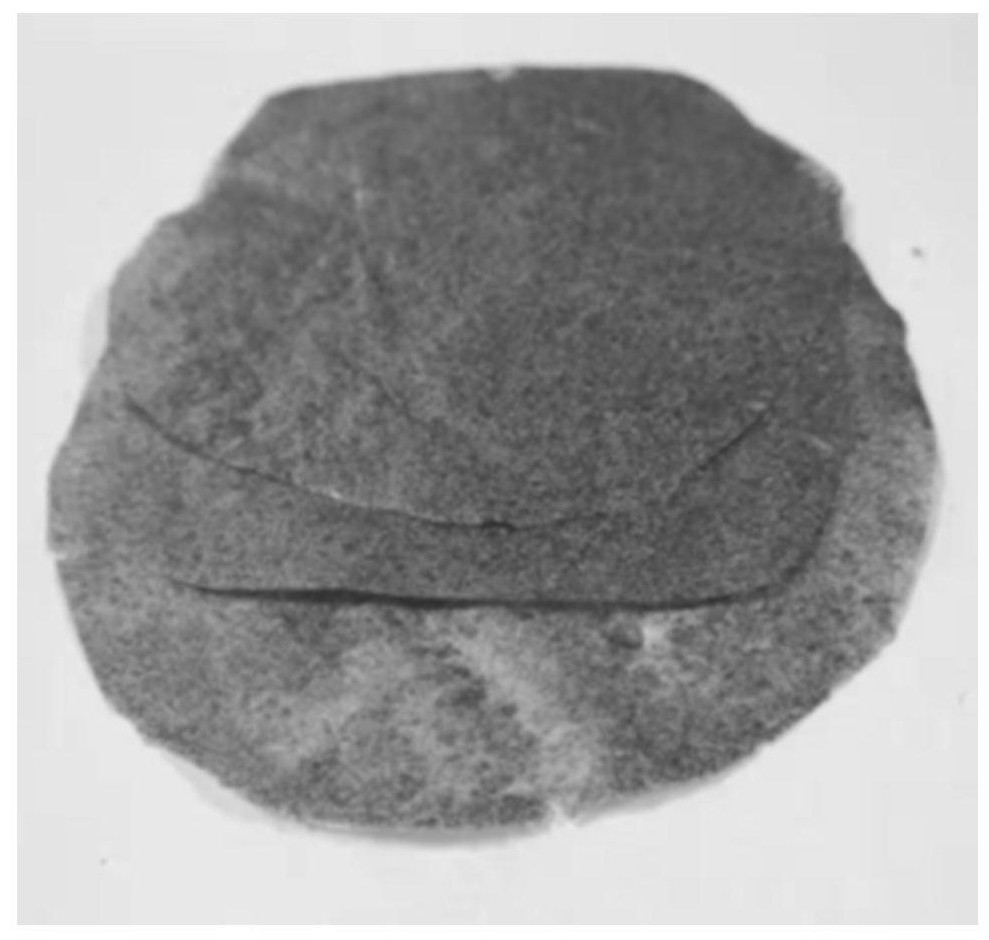

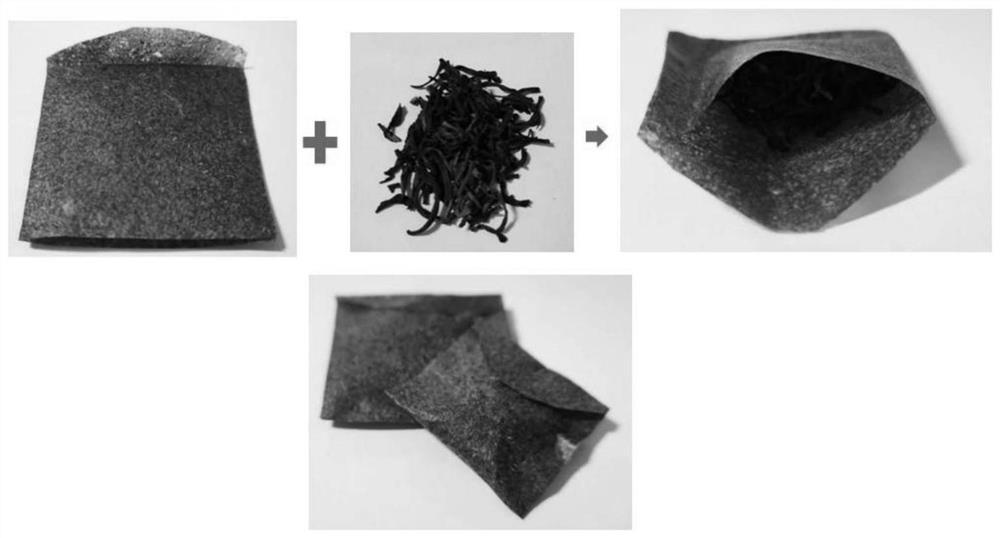

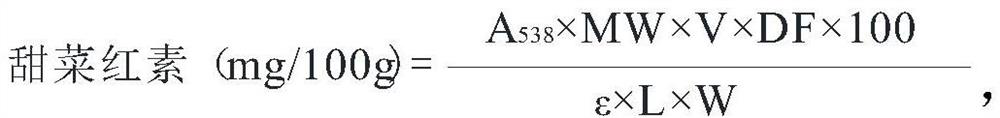

[0031] Select the peel of fresh red-skinned red-fleshed pitaya as raw material, clean it, remove the scales, arrange it into 5cm×15cm peels, and remove the outer waxy layer. The obtained pericarp was beaten at 10,000 rpm at 5°C for 40 seconds to obtain a peel slurry without exocarp; the temperature of the pericarp slurry was controlled to be ≤20°C, and the shearing machine was used to cut at 10,000 rpm for 2 minutes to make the obtained film-forming slurry uniform and fine for subsequent film formation Uniform; put 50g of film-forming slurry upside down on a clean smooth plastic plate, and use a special coating mold to coat it into a raw film embryo with a thickness of 1mm; dry the raw film embryo at a relative humidity of 65%RH and 28°C for 8 hours , peel off the film, can obtain the edible film of dragon fruit peel of color and luster bright red, thickness 0.05mm, water content 12% (betalain content is 42mg / 100g); Product such as figure 1 shown.

[0032] In this embodiment,...

Embodiment 2

[0034] Select the peel of fresh red-skinned red-fleshed pitaya as raw material, clean it, remove the scales, arrange it into 5cm×15cm peels, and remove the outer waxy layer. The obtained peel was beaten at 20000rpm at 10°C for 1min to obtain the peel slurry without the exocarp; 20% by weight deionized water was added; the temperature of the peel slurry was controlled to be less than 20°C, and the shearing machine was used to cut at 15000rpm for 1min so that the obtained The film-forming slurry is even and fine; pour 50g of the film-forming slurry into a clean glass plate frame and shake it for 3 minutes to obtain a uniform and smooth 1mm raw film embryo; An edible film of dragon fruit peel (betalain 30 mg / 100 g) with bright red color, a thickness of 0.03 mm and a water content of 12% was obtained.

[0035] In this example, the edible film was prepared by pouring the film method. Since the peel slurry needs to be diluted with water to a certain concentration, the peel slurry ha...

Embodiment 3

[0037]Select the peel of fresh red-skinned red-fleshed pitaya as raw material, clean it, remove the scales, arrange it into 5cm×15cm peels, and remove the outer waxy layer. The obtained peel was beaten at 8000rpm at 10°C for 2min to obtain a peel slurry without exocarp; add 1.0% glycerin, control the temperature of the peel slurry to ≤20°C, and use a shearer to cut at 25000rpm for 0.5min to make the obtained film-forming slurry Uniform and delicate; pour 30g of film-forming slurry on a smooth glass plate, and use a special coating mold to coat the raw film embryo with a thickness of 0.8mm; the raw film embryo is dried at 25°C for 5 hours and then peeled off to obtain a red color Bright, 0.02mm thick, 10% water content edible film of dragon fruit peel (containing betalain 20mg / 100g)

[0038] This embodiment adopts coating method to make edible film, and edible film keeps the betalain in the pericarp slurry, and color and luster is bright, is suitable as the lining paper such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com