Low-temperature extrusion-modified potato starch for improving quality of wholewheat deep-fried dough sticks and preparation method and application of low-temperature extrusion-modified potato starch

A potato starch and low-temperature technology is applied in the field of low-temperature extrusion modified potato starch and its preparation, which can solve problems such as inconsistency with consumption concepts, and achieve the advantages of reducing the dosage of chemical reagents, improving food quality, and improving gas production and gas holding capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

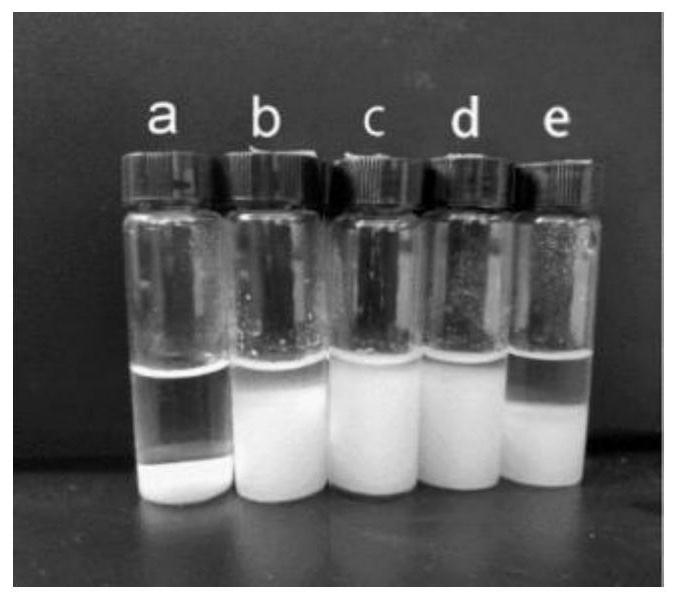

Image

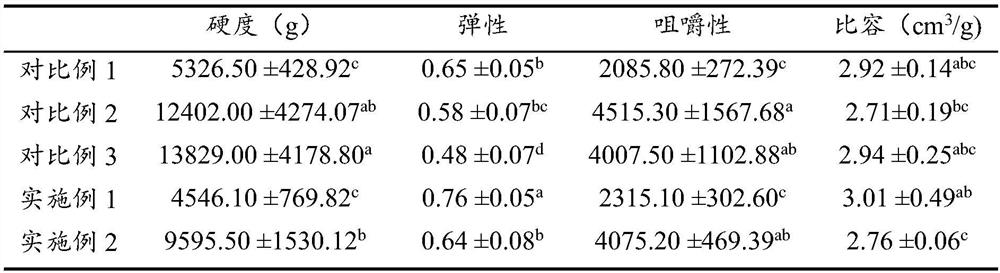

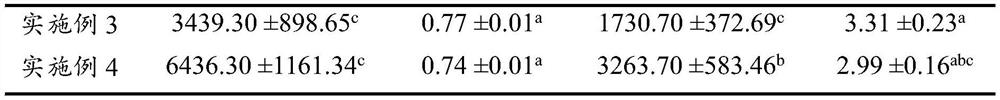

Examples

preparation example Construction

[0018] The invention provides a method for preparing low-temperature extrusion modified potato starch for improving the quality of whole wheat fried dough sticks, which comprises the following steps: performing low-temperature extrusion modification on potato starch to obtain low-temperature extrusion modified potato starch.

[0019] In the present invention, the low-temperature extrusion modification treatment is preferably carried out in a twin-screw extruder, and the extrusion temperature of the low-temperature extrusion modification is preferably 60-120° C.; the rotation speed of the twin-screw extruder is preferably 60-120r / min; the moisture content of the material during the low-temperature extrusion modification process is preferably 20-60wt.%. The present invention regulates the degree of gelatinization and degradation of starch in the low-temperature extrusion modification process by controlling the moisture content, extrusion temperature and screw speed, thereby ensur...

Embodiment 1

[0031] Preparation of low temperature extrusion modified potato starch:

[0032] When the rotational speed of the twin-screw extruder is 60r / min, the extrusion temperature is 60°C, and the moisture content of the material is 20wt.%, the potato starch is modified by low-temperature extrusion; the starch obtained by extrusion is dried to make the starch contain The water content is reduced to less than 14wt.%, and the particle size is smaller than 60 mesh through centrifugal crushing to obtain low-temperature extrusion modified potato starch.

[0033] Prepare materials according to the following mass parts: 5.8 parts of low-temperature extrusion modified potato starch, 52.2 parts of whole wheat flour, 1.74 parts of aluminum-free compound dough stick leavening agent, 0.81 parts of salt and 39.45 parts of water. The low-temperature extrusion modified potato starch is prepared by the above-mentioned method. Wherein, the gross mass of preparation raw material is 200g (5 fried dough...

Embodiment 2

[0040] Same as the condition parameters of Example 1, the difference is that the present embodiment injects moisture into the potato starch during the preparation of the modified potato starch by low-temperature extrusion, and the moisture content of the material is 60wt.%; the extrusion temperature is 90 ℃; the total mass of raw materials for preparation is 200g, the mass fraction of low-temperature extrusion modified potato starch is 1.16 parts, and the mass fraction of whole wheat flour is 56.84 parts, that is, the dosage of low-temperature extrusion modified potato starch is 2.32g, and the dosage of whole wheat flour It is 113.68g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com