Continuous textile waste gas treatment device

A waste gas treatment device and continuous technology, which is applied in the directions of transportation and packaging, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of endangering human health, low treatment efficiency, high maintenance cost, etc., to improve the treatment effect and reduce the The effect of maintenance and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

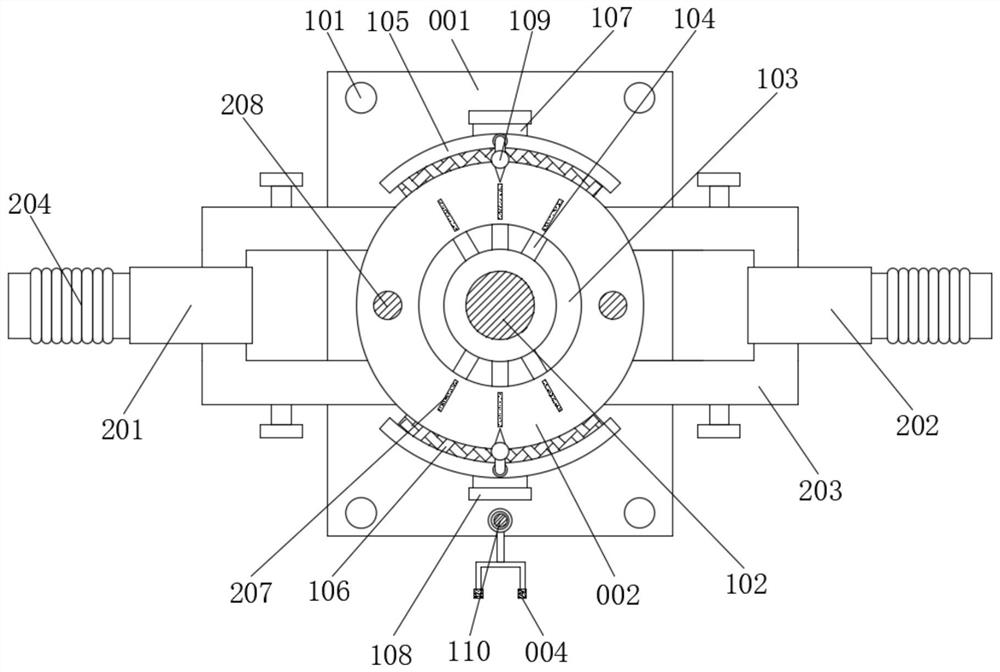

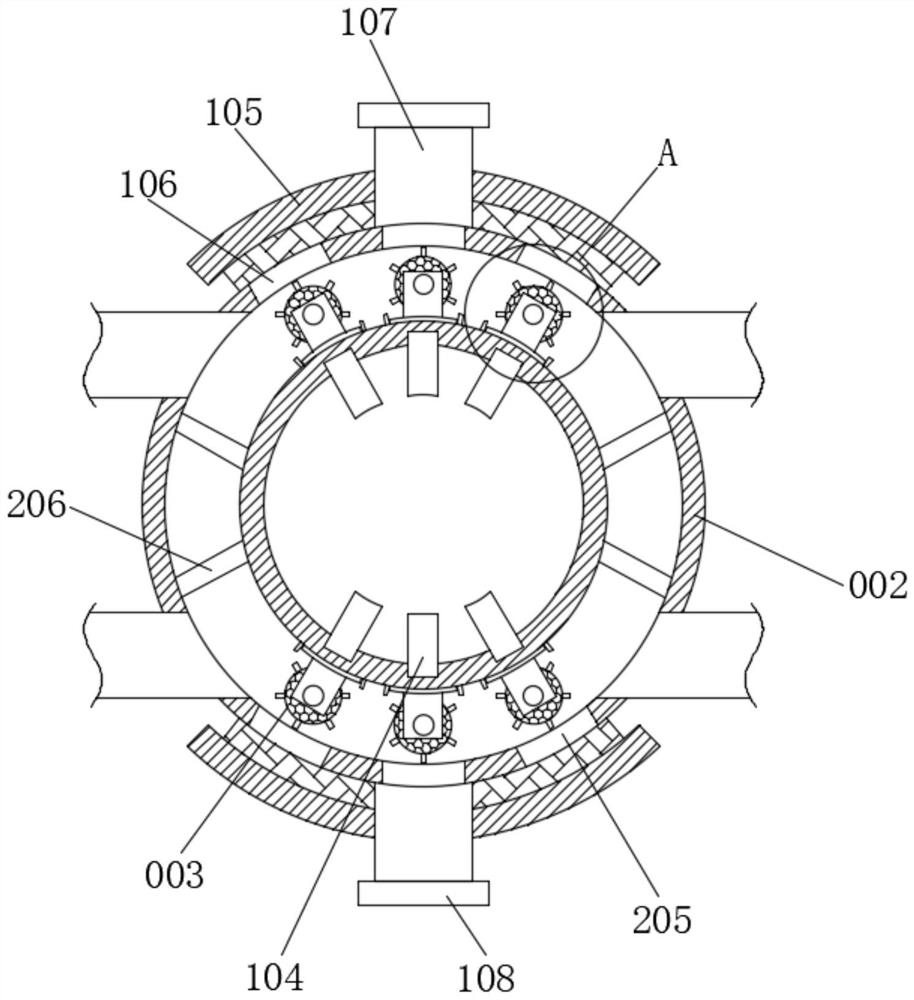

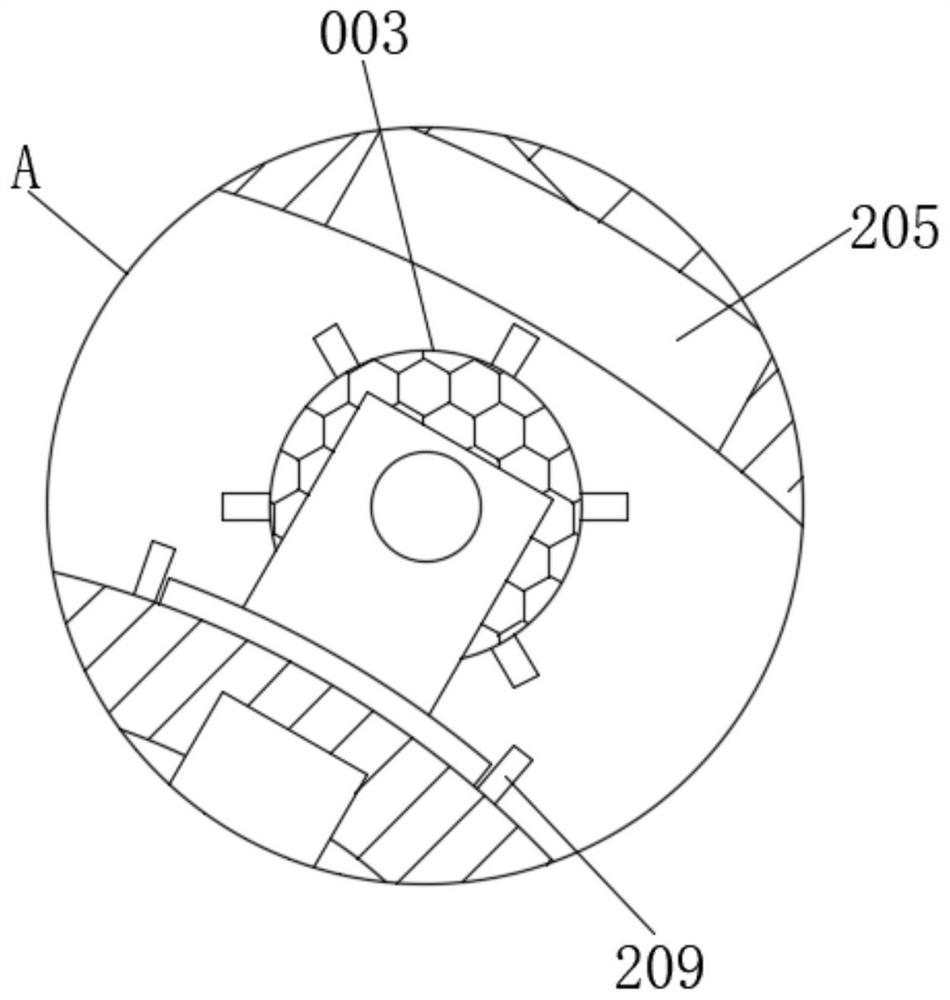

[0045] see Figure 1-2 , Figure 4 and Figure 7 , a continuous textile waste gas treatment device, including a mounting plate 001, an annular processing pipe 002, an adsorption ball mechanism 003, and an auxiliary replacement mechanism 004. There are four mounting holes 101 distributed in a rectangular array inside the mounting plate 001, which can be passed through The installation hole 101 installs and fixes the device, and the bottom of the annular processing pipe 002 is provided with a hanging rod 110 fixedly connected to the front side of the installation plate 001. A connection ring 103 is connected, and a plurality of electromagnets 104 are fixedly connected to the outer wall of the connection ring 103. One end of the electromagnet 104 away from the connection ring 103 is embedded in the outer wall of the ring-shaped processing tube 002. The electromagnet 104 can not only play a role in fixing the ring-shaped processing tube. 002, after the electromagnet 104 is energ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com