Body-in-white plug welding technological method

A welding process and body-in-white technology, which is applied in welding equipment, manufacturing tools, metal processing, etc., can solve problems such as incomplete solder joints, undercuts, and increased production costs, so as to reduce production costs, increase production tempo, reduce Effects of weld underfill and undercut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

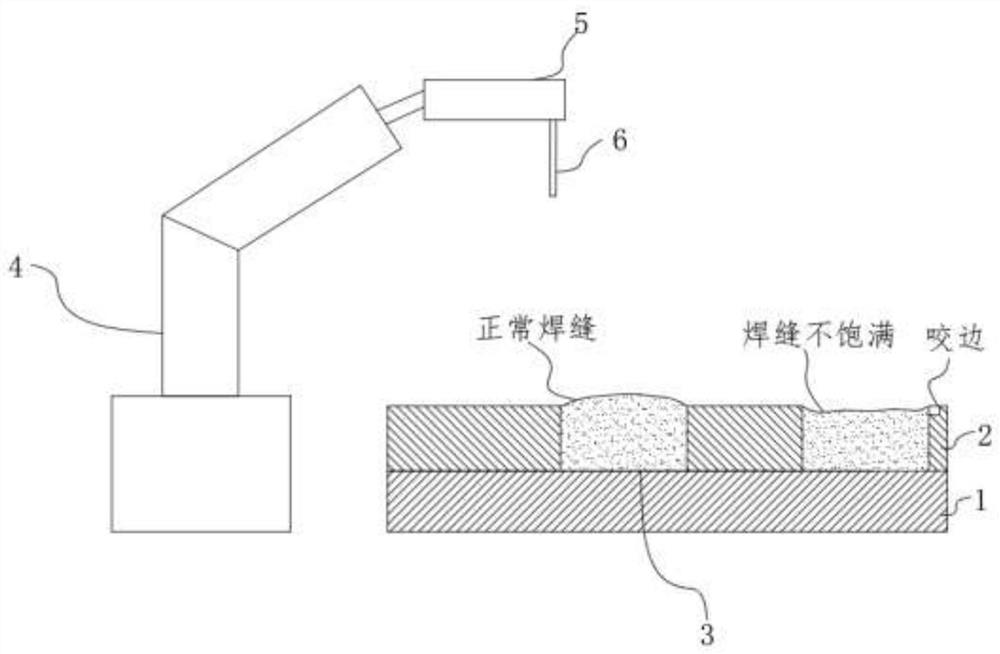

[0028] see Figure 1-2 As shown, the present invention is a body-in-white plug welding process, a body-in-white plug welding process, comprising an upper plate 1, a lower plate 2 and a robot 4, consisting of the following steps:

[0029] A: Set the upper plate 1 on the surface of the lower plate 2, and the maximum gap must be less than 0.8mm;

[0030] B: The upper plate 1 and the lower plate 2 need to be cleaned within 150mm of the 3rd side of the plug welding hole before welding. Cleaning before welding can prevent other debris from entering the weld and affect the welding quality;

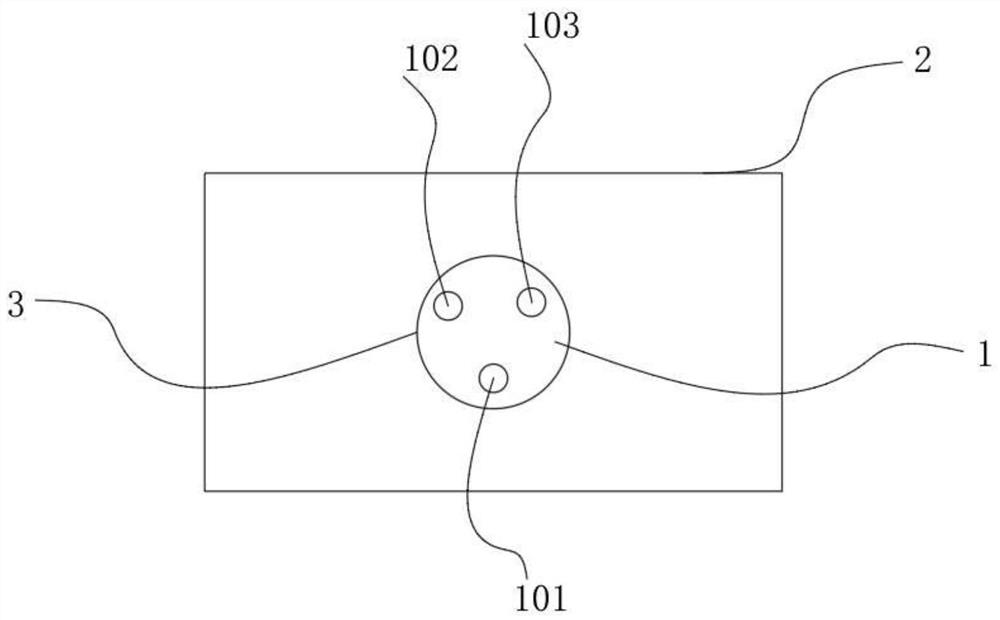

[0031] C: A number of plug welding holes 3 are opened on the surface of the upper plate 1 in a multi-stage manner, and the first welding point 101, the second welding point 102 and the third welding point 103 are arranged in the plug welding hole 3, and the first welding point 101 is set in the plug welding hole 3. The position of one welding point 101 is set as "down", the positions of the seco...

Embodiment 2

[0042] see Figure 1-2 As shown, the present invention is a body-in-white plug welding process method, which adopts a segmented multi-point welding method, and the method steps are as follows:

[0043] Step 1: Divide the position of the plug welding hole, and divide the points of the plug welding hole 3. The position and number of points are determined according to the size of the 3 digits of the plug welding hole. The first welding point 101 is the first welding point, and the number The welding sequence of the second welding point 102 and the third welding point 103 is interchangeable;

[0044] Step 2: Adjust the welding trajectory of the robot 4. The welding trajectory and angle of the robot 4 depend on the number of plug welding points and the inclination angle of the plate;

[0045]Step 3: Adjust the welding parameters, different welding parameters will be selected for different plug welding points, and the welding parameters need to be decreased point by point.

Embodiment 3

[0047] see Figure 1-2 As shown, the present invention is a kind of plug welding welding process for a body in white, wherein the welding angle of the robot 4 mainly considers the directivity of the arc, the horn-shaped arc will cause undercut to the edge of the plug welding hole 3, and the welding angle of the robot It needs to be vertical or inwardly inclined, and the material of the welding wire 6 can be HO8Mn2SiA, which has a series of excellent welding performances such as high production efficiency, stable and reliable welding quality, beautiful shape, and large penetration depth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com