Carbon nanotube/carbon fiber composite material as well as preparation method and application thereof

A technology of carbon nanotubes and composite materials, which is applied in the field of carbon nanotube/carbon fiber composite materials and their preparation, can solve problems such as limitations, debonding between layers, and weak ability to resist loads in the thickness direction, so as to improve lightning protection effects and enhance Interfacial bonding strength and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a carbon nanotube / carbon fiber composite material. The carbon nanotube / carbon fiber composite material includes from top to bottom: a carbon nanotube super-aligned film layer, a glass fiber prepreg layer, and a carbon nanotube-containing layer. Array of carbon fiber prepreg layers. The carbon nanotube super-parallel film layer includes a layer of carbon nanotube super-parallel film layer, the carbon nanotube super-parallel film layer is composed of 1000 layers of carbon nanotubes, and the thickness is 10 μm; the glass fiber prepreg The layer includes 3 layers of glass fiber prepreg, and the thickness of each layer of glass fiber prepreg is 100 μm; the carbon fiber prepreg layer containing carbon nanotube arrays includes 30 layers of carbon fiber prepreg layers containing carbon nanotube arrays.

[0055] The preparation method of the carbon nanotube / carbon fiber composite material described in this embodiment comprises the following steps:

[00...

Embodiment 2

[0060] This embodiment provides a carbon nanotube / carbon fiber composite material. The only difference from Example 1 is that the carbon nanotube super-aligned film layer is composed of 100 layers of carbon nanotubes, and the carbon nanotube super-aligned The thickness of the film layer is 1 μm.

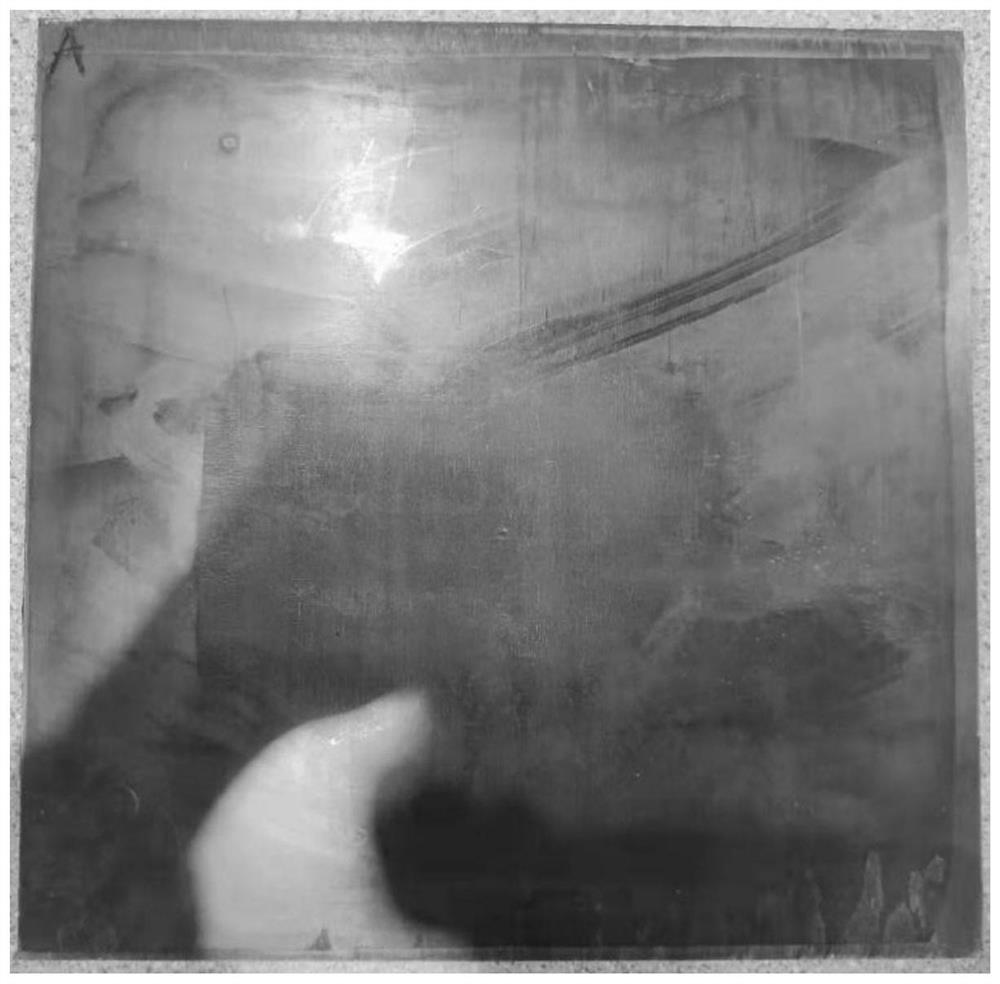

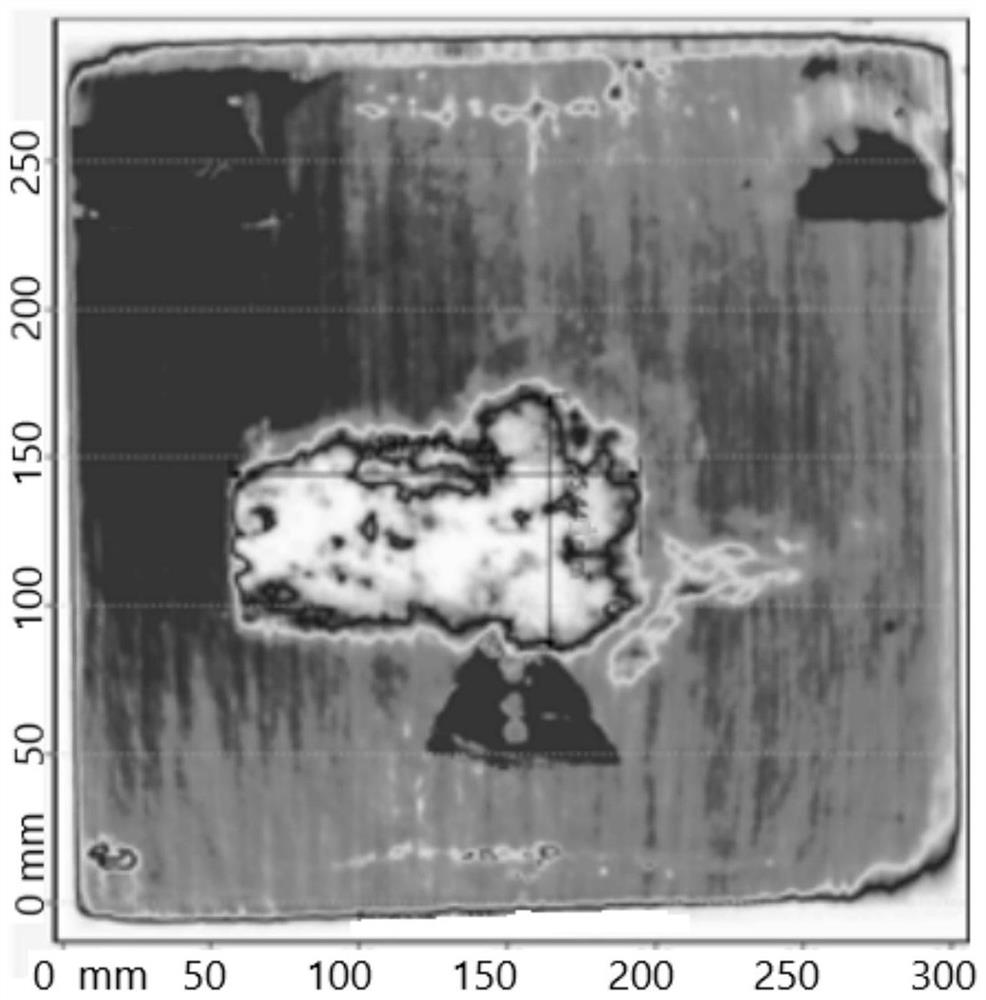

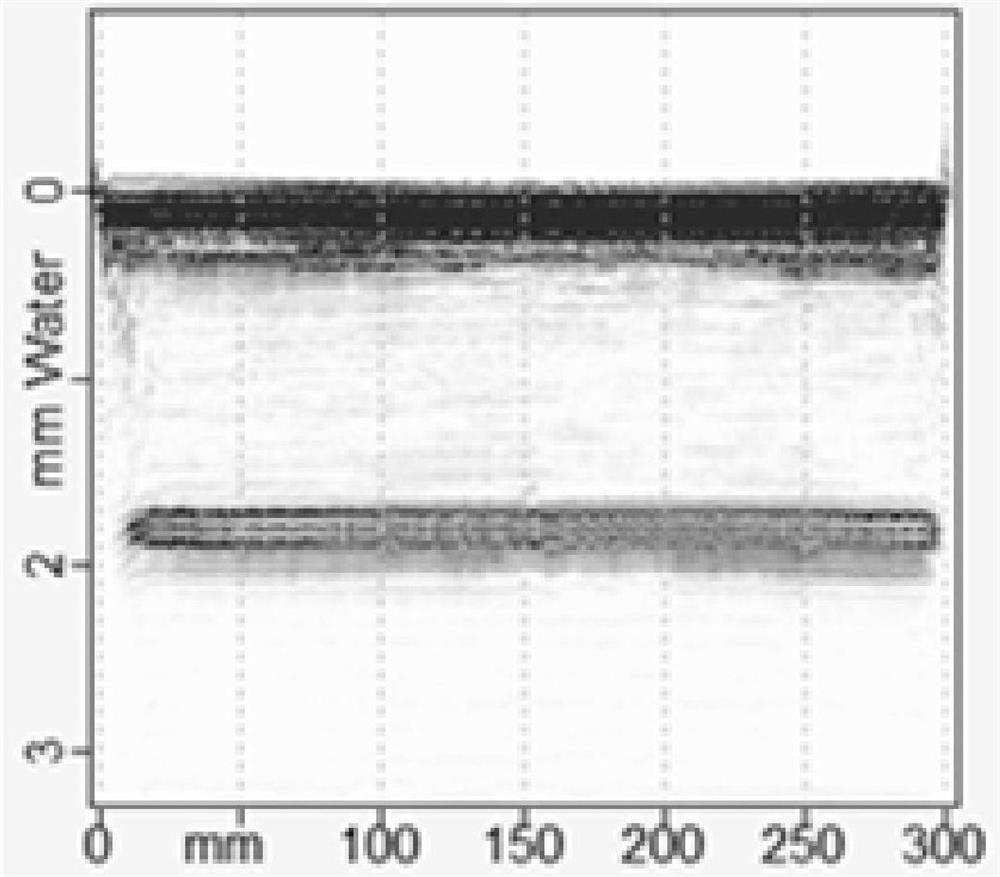

[0061] Carry out 100kA lightning impact test to the carbon nanotube / carbon fiber composite material prepared in this embodiment, and adopt ultrasonic wave to evaluate composite material damage, Figure 4 The carbon nanotube / carbon fiber composite material prepared for embodiment 2 is subjected to the appearance topography figure after lightning strike, Figure 5 The carbon nanotube / carbon fiber composite material prepared for embodiment 2 is through the non-destructive testing surface map after lightning strike, Image 6 Cross-sectional view of non-destructive testing of the carbon nanotube / carbon fiber composite material prepared in Example 2 after being struck by lightning. Depen...

Embodiment 3

[0063] This embodiment provides a carbon nanotube / carbon fiber composite material. The only difference from Example 1 is that the carbon nanotube super-aligned film layer is composed of 500 layers of carbon nanotubes, and the carbon nanotube super-aligned The thickness of the film layer was 5 μm.

[0064] Carry out 100kA lightning impact test to the carbon nanotube / carbon fiber composite material prepared in this embodiment, and adopt ultrasonic wave to evaluate composite material damage, Figure 7 The carbon nanotube / carbon fiber composite material prepared in Example 3 is subjected to the appearance topography figure after lightning strike, Figure 8 The carbon nanotube / carbon fiber composite material prepared for embodiment 3 is subjected to non-destructive testing surface diagram after lightning strike, Figure 9 It is a cross-sectional view of non-destructive testing of the carbon nanotube / carbon fiber composite material prepared in Example 3 after being struck by lightn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com