Water permeable brick and preparation method thereof

A technology of permeable bricks and production methods, which is applied in the direction of manufacturing tools, ceramic products, and other household appliances, etc., which can solve the problems of short maintenance time of water retention performance and insufficient structural strength of water retention and permeable bricks, so as to improve the local environment and climate and extend the duration Effect of time, good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] b. Preparation of modified absorbent cotton filling block:

[0036] b 1 . Put the absorbent cotton in the cement mortar and soak it, so that the cement mortar fully soaks the absorbent cotton, and obtains the cement mortar soaked absorbent cotton. Specifically, the cement mortar consists of cement, fine sand and water, wherein the mass ratio of cement to fine sand is 1: (1-3), and the particle size of the fine sand is optimally 60-100 mesh. The cement mortar The consistency is 10-20, so that the cement mortar can enter the pore structure of the absorbent cotton, so that the absorbent cotton can harden and have a certain supporting strength.

[0037] b 2 . Soak the cement mortar with absorbent cotton and dry until hardened. For example, the absorbent cotton is soaked in cement mortar for 10-48 hours, then taken out, drained and dried naturally until the cement mortar in the absorbent cotton solidifies and hardens.

[0038] step b 1 with step b 2 Among them, by adju...

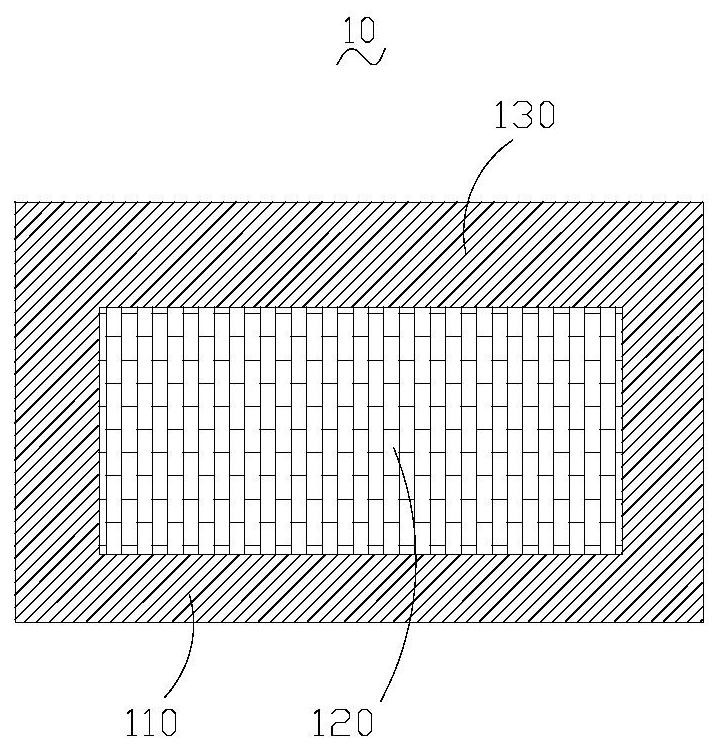

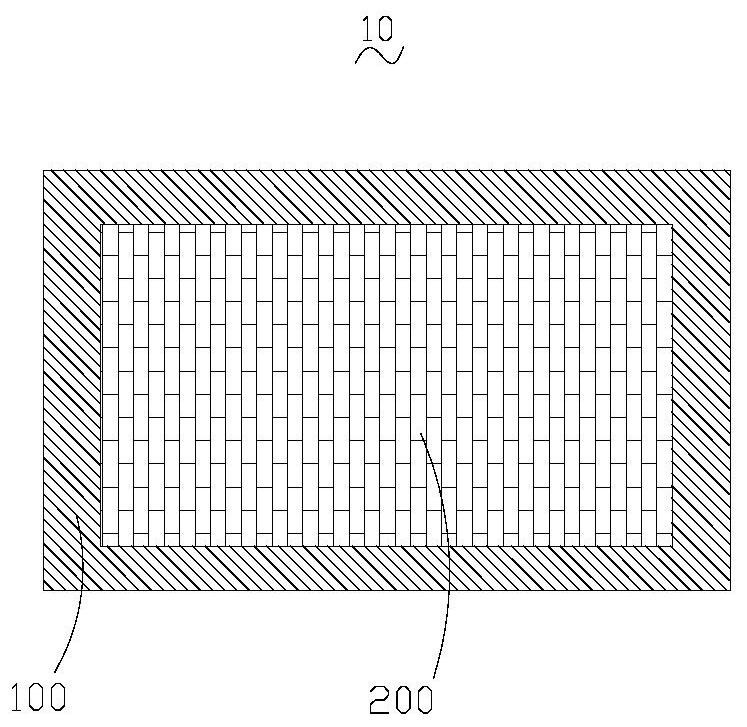

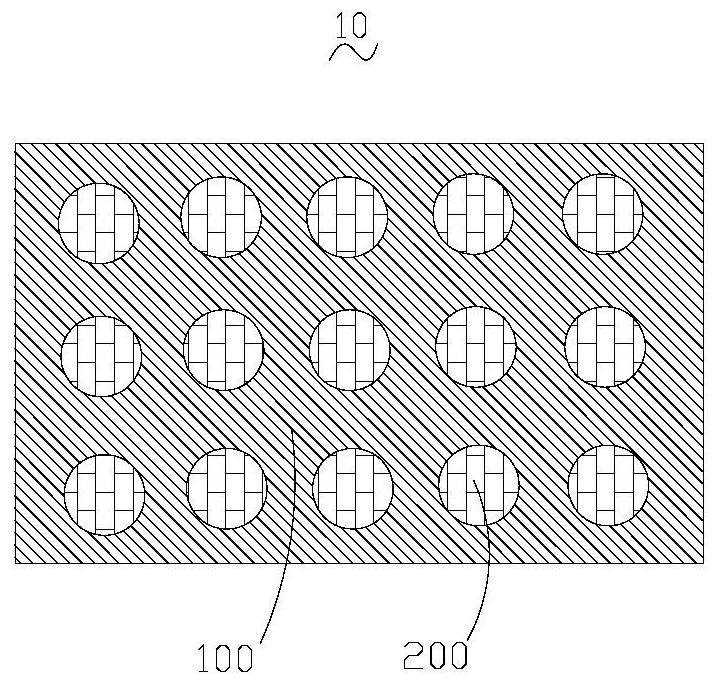

Embodiment 1

[0051] Cement is used as an adhesive, a mixture of coarse sand, fly ash, and crushed construction waste is used as a supporting aggregate, and a foaming agent is used as a pore-forming agent to form a permeable skeleton 100 by using a mold. The thickness ratio of the bottom, water-retaining part and top of the permeable skeleton is 1:1:1. A large water-retaining chamber is set in the water-retaining part, and the water-retaining chamber is filled with modified absorbent cotton filling blocks. The modified absorbent cotton filling block is prepared by the following method: the waste sponge is placed in cement mortar and soaked for 48 hours, so that the cement mortar fully soaks the waste sponge to obtain the cement mortar soaked absorbent cotton; the cement mortar soaked absorbent cotton is naturally drained, Naturally dry until the cement mortar is solidified; according to the shape and size of the water-retaining chamber, the hardened cement mortar is infiltrated with water-ab...

Embodiment 2

[0053] Cement is used as an adhesive, a mixture of coarse sand, fly ash, and crushed construction waste is used as a supporting aggregate, and a foaming agent is used as a pore-forming agent to form a permeable skeleton 100 by using a mold. The thickness ratio of the bottom, water-retaining part and top of the permeable skeleton is 1:2:2. A large water-retaining chamber is set in the water-retaining part, and the water-retaining chamber is filled with modified absorbent cotton filling blocks. The preparation method of the modified absorbent cotton filling block is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com