Direct-drive type electric top drive for well drilling

A direct-drive, electric technology, applied in drilling equipment, electric components, electromechanical devices, etc., can solve the problems of complex structure of mechanical variable-speed transmission mechanism, high processing technology requirements, and high difficulty in top drive lubrication, so as to reduce the failure rate of equipment use. effect on maintenance intensity, avoidance of oil spills, and enhanced ability to cope with drilling accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

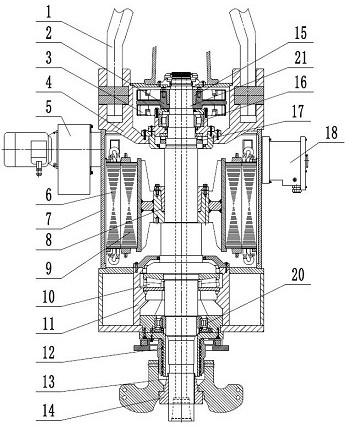

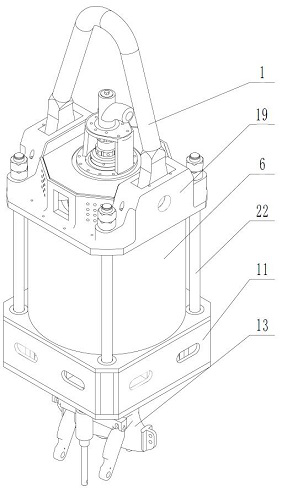

[0018] A direct-drive electric top drive for drilling, including a main shaft 21, a motor 6 and a motor stator housing 7; the motor 6 is installed in the motor stator housing 7, and an upper box 4 is installed on the upper end of the motor stator housing 7 , the lower end is equipped with a load-bearing box 11; the main shaft 21 runs through the upper box 4, the motor 6 in the motor stator housing 7 and the load-bearing box 11 from top to bottom; the motor rotor 9 in the motor 6 passes through the motor The elastic taper sleeve 8 is connected with the main shaft 21; the disc brake assembly 3 is installed in the upper box body 4; the brake disc 2 in the disc brake assembly 3 is connected with the main shaft 21 through the brake elastic taper sleeve 15; the load-bearing The upper part in the box body 11 is provided with a load-bearing bearing 10, and the load-bearing bearing 10 is connected with the main shaft 21;

[0019] As an optimization, a thrust bearing 17 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com