Equipment used for fly ash treatment

A fly ash and equipment technology, applied in the field of fly ash treatment, can solve the problems of low combustion efficiency, spending a lot of time in fly ash heating and combustion, affecting flue gas treatment and purification, etc., to achieve recycling, shorten heating time and Burning time, the effect of realizing recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

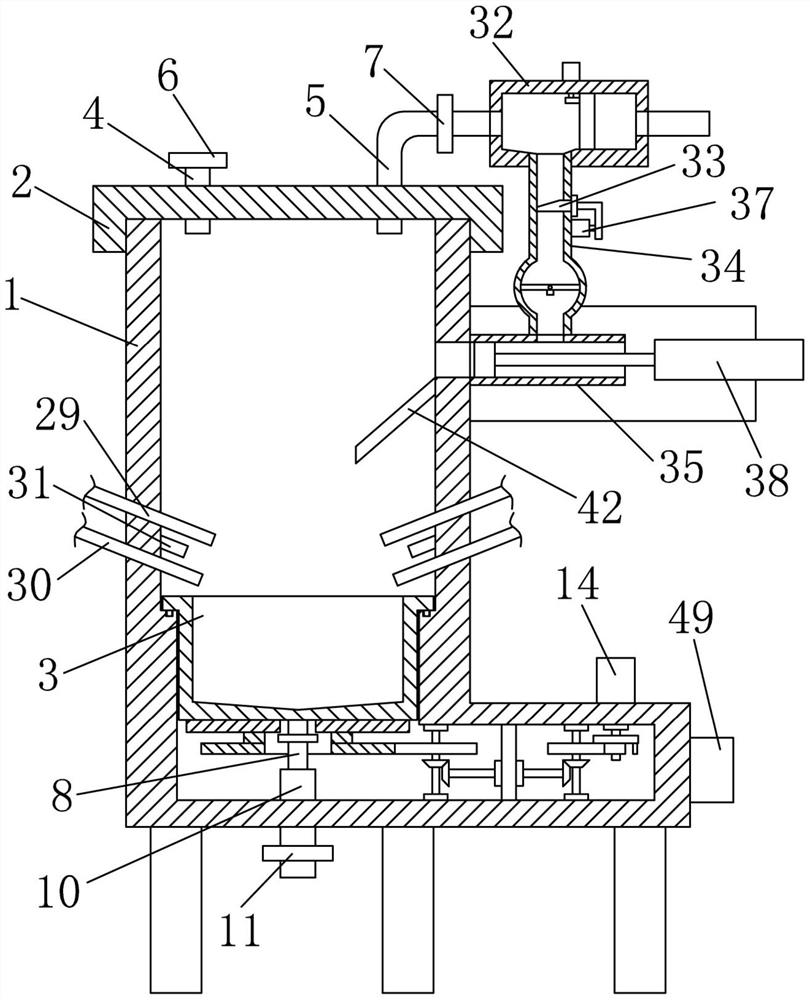

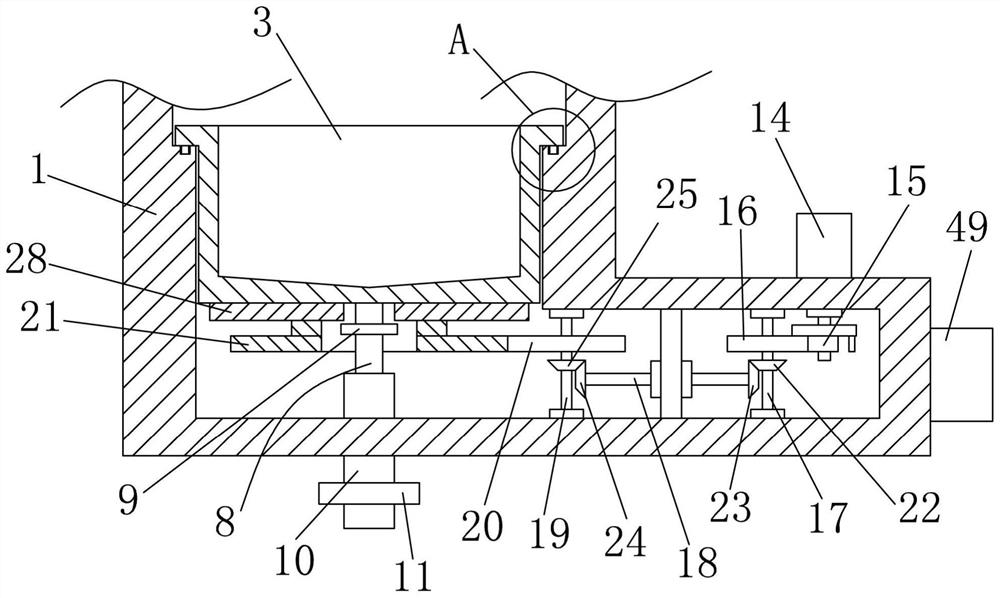

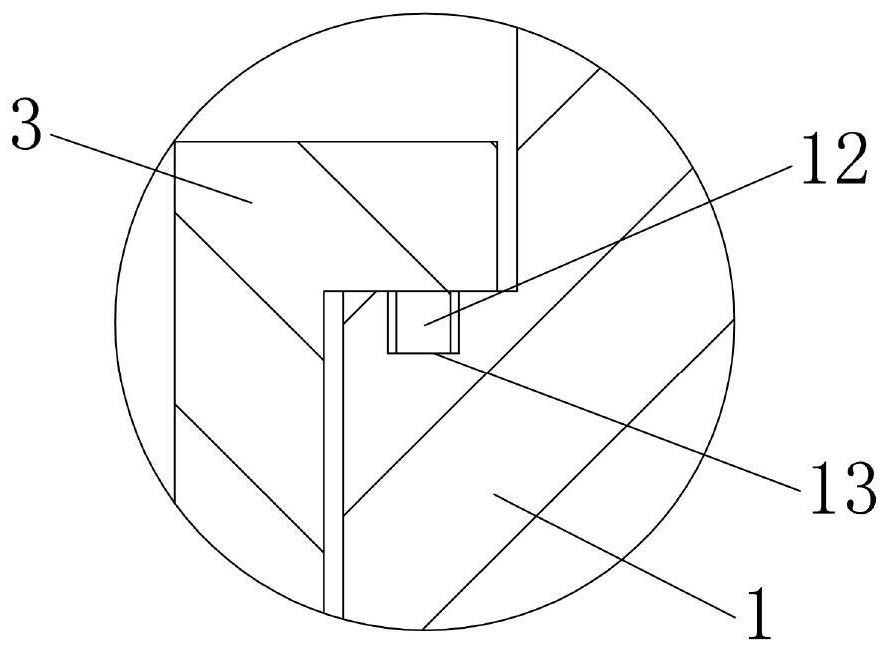

[0024] Embodiment: a kind of equipment for fly ash processing, such as Figure 1-Figure 8 As shown, it includes a furnace body 1, a furnace cover 2, a crucible 3, a flue gas treatment mechanism, and a crucible driving mechanism. The furnace cover 2 covers the furnace body 1, and the top of the furnace cover 2 is respectively provided with fly ash feeding port 4 and smoke exhaust port 5, the fly ash feed port 4 is equipped with a feed valve 6, the smoke exhaust port 5 is equipped with a smoke exhaust valve 7, and the smoke exhaust port 5 is connected with the flue gas processing mechanism The two sides of the middle part of the furnace body 1 are provided with an ignition device, the crucible 3 and the crucible driving mechanism are located in the furnace body 1, the crucible 3 is located below the ignition device, and the top of the crucible 3 is in contact with the furnace body 1, the crucible driving mechanism is located below the crucible 3, the crucible driving mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com