Tunneling type MEMS air pressure sensor and application thereof

An air pressure sensor and tunneling technology, used in instruments, measuring fluid pressure, measuring fluid pressure through electromagnetic components, etc., can solve the problems of large air pressure sensors, difficult to realize the miniaturization design of sensors, etc., to achieve a wide application space, use Wide range of highly sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

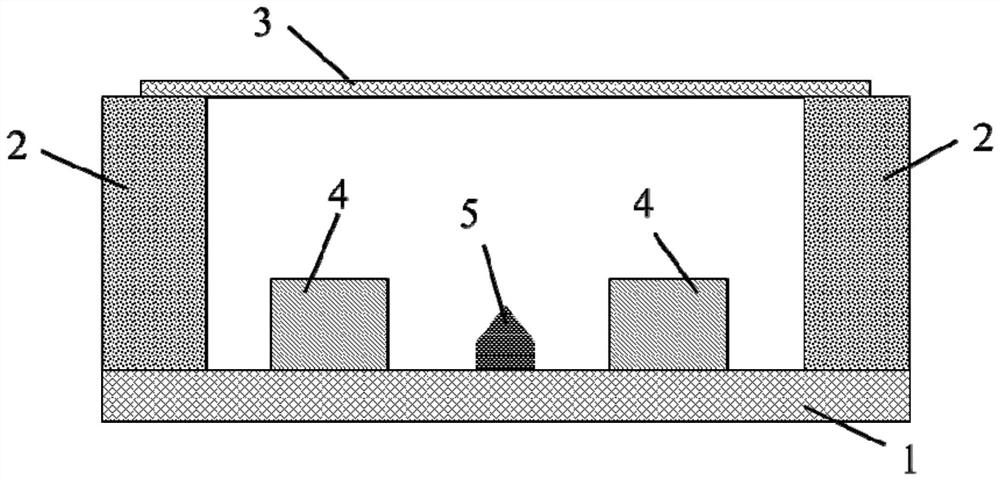

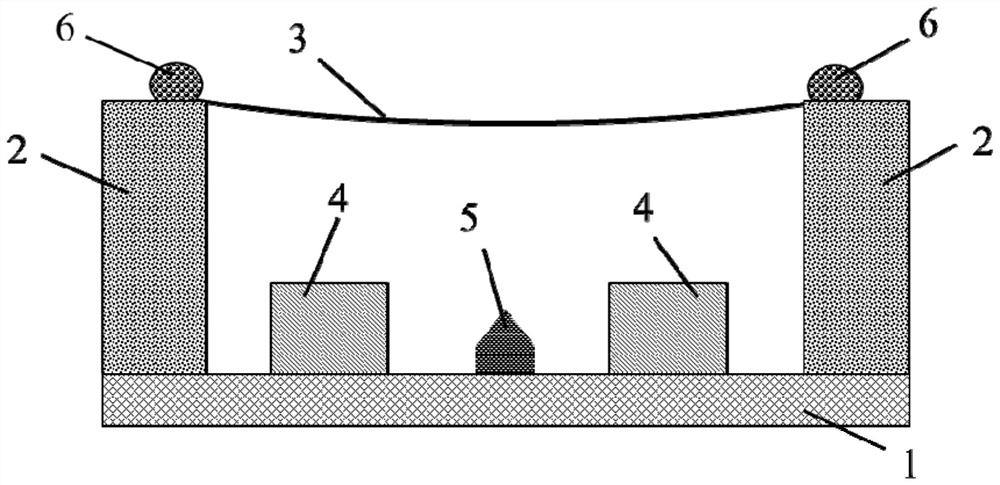

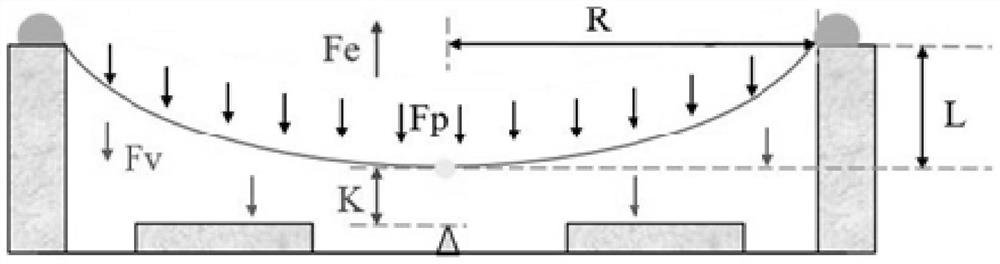

[0052] This embodiment provides a volume of 1.99098×10 -13 m 3 The tunneling MEMS air pressure sensor (the side view of its structure see figure 1 ), the tunneling MEMS air pressure sensor comprises a substrate 1 and an annular metal electrode 2 and a graphene film 3 arranged on the substrate in sequence; the graphene film 3 covers the hollow cavity of the annular metal electrode 2, And the edge of the graphene film 3 is fixed on the ring-shaped metal electrode 2 through an adhesive package; the base 1 is also provided with a ring-shaped metal grid 4, and the ring-shaped metal grid 4 is mounted on the ring-shaped metal electrode 2 In the hollow cavity; the substrate 1 is also provided with a drain 5; the drain is arranged in the center of the hollow cavity of the ring-shaped metal gate;

[0053] The material of the annular metal electrode described in this embodiment is gold; the material of the annular metal grid is metallic gold; the material of the drain is metallic gold;...

Embodiment 2

[0062] The difference from Example 1 is that the thickness of the graphene film is 30nm.

Embodiment 3

[0064] The difference from Example 1 is that the thickness of the graphene film is 70nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap