Battery device capable of monitoring electrode stress change in real time, battery adopting battery device and application of battery device

A technology of stress change and real-time monitoring, which is applied in secondary batteries, electrochemical generators, and measurement of the properties and forces of piezoresistive materials. It can solve the problems of long distances in practical applications, complicated research methods, high costs and time problem, to achieve the effect of great practical significance, simple representation, and efficient representation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

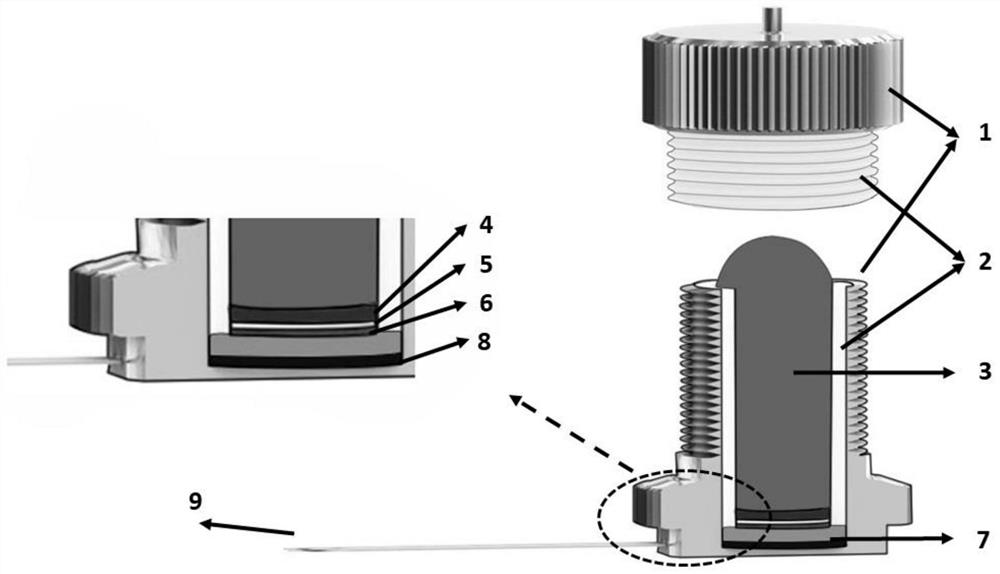

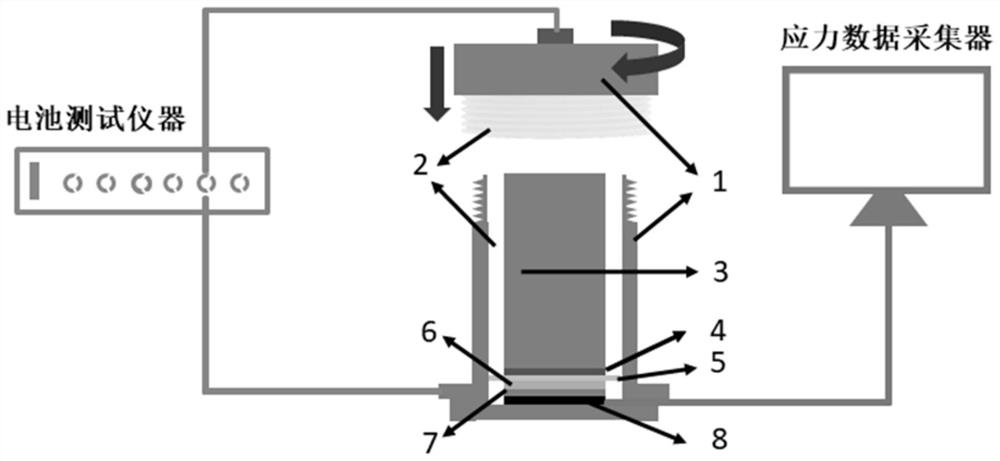

[0038] refer to figure 1 , a battery device that can monitor electrode stress changes in real time, comprising:

[0039]The metal casing 1 is composed of an upper metal casing and a lower metal casing. In this embodiment, the upper metal casing of the metal casing 1 is a positive electrode casing, and the lower metal casing is a negative electrode casing. The same can be done in reverse. The longitudinal inner wall of the upper metal shell has internal threads, and the longitudinal outer wall of the lower metal shell has external threads.

[0040] The hollow cylindrical insulating part 2 is composed of an upper insulating hollow cylinder and a lower insulating hollow cylinder. The longitudinal inner and outer walls of the upper insulating hollow cylinder are respectively provided with internal threads and external threads. The thread cooperates with the internal thread of the upper metal shell to realize the connection, and the internal thread cooperates with the external th...

Embodiment 2

[0050] The basic structure is as in Example 1, and its preparation process:

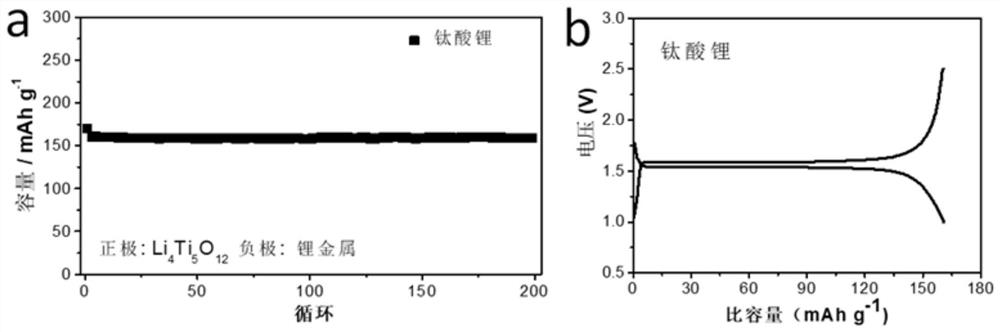

[0051] According to the process from bottom to top, place the metal gasket 7 flatly on the surface of the thin film pressure sensor 8, and then use a wire to connect the metal gasket and the negative electrode case. Put the negative pole piece 6 on the surface of the gasket, and the negative pole piece 6 is metal lithium foil, and then put the separator Celgard 2400 and the positive pole piece 4 in sequence (the lithium titanate slurry is coated on the aluminum foil current collector). Choose to dissolve 1mol / L Li PF 6 EC: DEC (volume ratio 1:1) mixed solution organic electrolyte, take an appropriate amount and add it between the electrode and the diaphragm. Afterwards, put the lower insulating hollow cylinder into the negative electrode case, insert the metal solid cylinder 3 into the lower insulating hollow cylinder, and press it on the positive pole piece 4 . Finally, screw the upper insulating ...

Embodiment 3

[0055] The basic structure is as in Example 1, and its preparation process:

[0056] According to the process from bottom to top, place the metal gasket 7 flatly on the surface of the thin film pressure sensor 8, and then use a wire to connect the metal gasket and the negative electrode case. Put the negative electrode sheet 6 on the surface of the gasket (the active negative electrode material silicon slurry is dispersed on the surface of the copper current collector), and then put the intermediate piece 5 (diaphragm Celgard2400) and the positive electrode sheet 4 (the lithium iron phosphate slurry is coated on the aluminum foil current collector). Choose to dissolve 1mol / L Li PF 6 EC: DEC (volume ratio 1:1) mixed solution organic electrolyte, take an appropriate amount and add it between the electrode and the diaphragm. Afterwards, put the lower insulating hollow cylinder into the negative electrode case, insert the metal solid cylinder 3 into the lower insulating hollow c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com