Diaphragm and battery containing diaphragm

A diaphragm and battery technology, applied in the fields of diaphragm and its preparation method, batteries containing the diaphragm, and diaphragm modification layer, can solve the problems of reducing the ductility of the diaphragm, increasing the weight and thickness of the diaphragm, and achieving weight reduction, increased absorption speed, The effect of increasing the wetting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method of preparing the diaphragm modifier, comprising the steps of:

[0037] a) Prepare solutions containing the peptide material;

[0038] b) The solution was applied to at least one side surface of the diaphragm substrate to obtain a modifying layer obtained by obtaining the diaphragm.

[0039] The present invention also provides the preparation method of the diaphragm comprising the steps of:

[0040] 1) Prepare solutions containing the peptide material;

[0041] 2) The solution was applied to at least one side surface of the diaphragm substrate to prepare the separator.

[0042] According to the present invention, the step a) or step 1) specifically: dissolves the peptide material into the solvent to obtain a solution containing the peptide material.

[0043] In accordance with the present invention, in step b) or step 2), the coating can be spin coated or scraped.

[0044] In accordance with the present invention, in step b) or st...

Embodiment 1

[0053] Preparation of peptide material coating diaphragm:

[0054] S1: 0.1 mmol oligopeptide-6 (palmitum oligide) was added to 5 ml of 0.01 M NaOH aqueous solution, and then the pH of about 7 was adjusted with concentrated hydrochloric acid to obtain an oligopeptide solution;

[0055] S2: The oligopeptide solution obtained by step S1 is uniformly coated with a spin coated manner to a substrate material as a diaphragm (15 μm) of polypropylene, and then 60 ° C for vacuum drying 12h;

[0056] S3: washed with deionized water, and then dried at 60 ° C for 12 h at 60 ° C to give a polypropylene separator having an oligopeptide coating (2 μm thickness).

[0057] Preparation of positive electrode sheet: Polyacrylic acid (PAA) and PEO are dissolved in a acetonitrile solution in the mass of 1: 4, and the PVDF is a binder, and the positive electrode active material is added to the electrode active material. Get the positive slurry. In the mixture, the solid component contains 86 wt.% Cobalta...

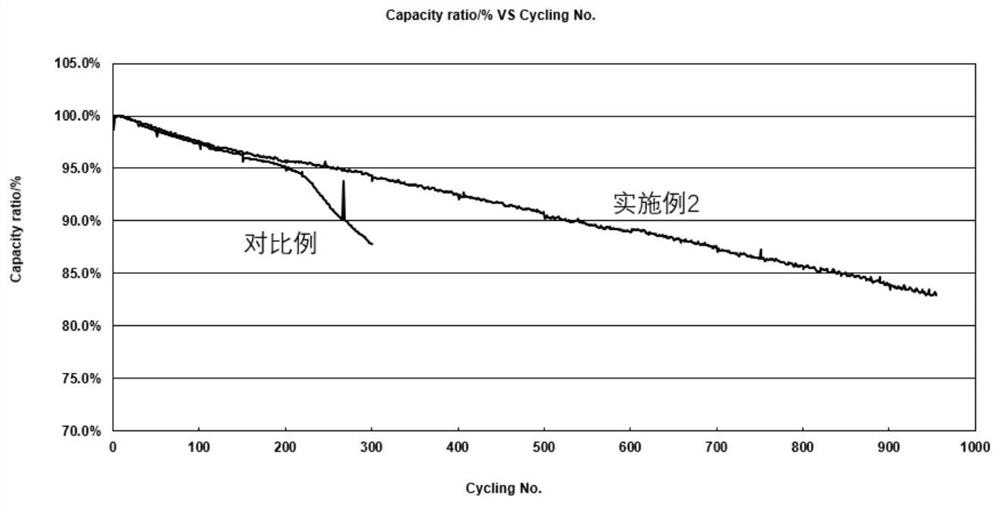

Embodiment 2

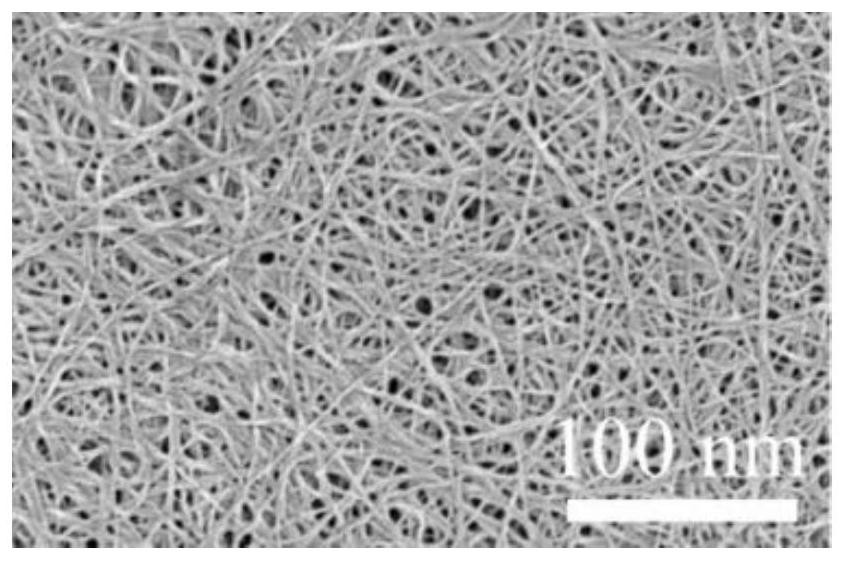

[0060] Preparation of peptide material coating diaphragms:

[0061] In the present embodiment, the two-step-derived polypeptide material is selected by the end-based, and the preparation method is as follows:

[0062] S1: dissolved 10, 12-twenty-fifty-fifty-fifty-carbon acid (0.24 mmol) into 20 mL DMF, add O-benzotriazole-N, N, N ', N'-tetramethylurea tetrafluoroboric acid (TBTU) (0.24 mmol) and N, N-diisopropylamine (DIEA) (0.24 mmol), then electromagnetic stirring for 30 minutes to activate carboxyl groups. 0.20 mmol gagagag was dissolved in 10 ml of DMF, and the solution was added dropwise to the above mixing liquid, and the ice water bath was stirred for 3 h, then the excess DMF was removed. The remaining solid was dissolved in 10 mL of 0.1 M NaOH, and then precipitated with concentrated hydrochloric acid, then washed with deionized water. The above dissolved precipitated washing process was repeated multiple times, and then the dried dried to obtain a powder sample C. 25 -Gag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com