Microbial fermentation pig feed and preparation process thereof

A technology of microbial fermentation and pig feed, applied in animal feed, animal feed, bacteria used in food preparation, etc., can solve problems such as the inability of fermentation bacteria to grow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

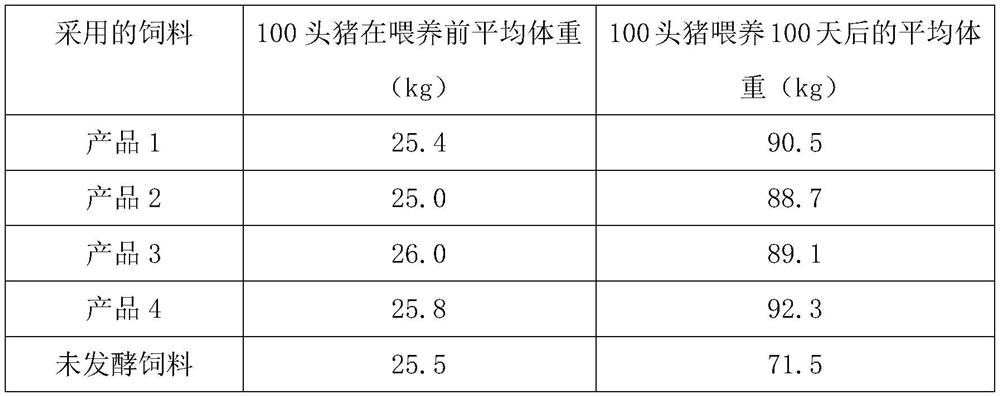

Examples

Embodiment 1

[0021] A microbial fermented pig feed, comprising the following raw materials in parts by weight: 20 parts of barley flour, 15 parts of bran powder, 20 parts of corn cob powder, 10 parts of beans, 8 parts of fish meal, 15 parts of potato flour, 15 parts of vegetables and fruits, 2 parts of sodium bicarbonate, 10 parts of bacterial liquid.

[0022] The mass ratio of soybean hulls and soybean meal in beans is 3:5. The fish meal is a powder made from dried small fish, and the fresh weight of the dried small fish does not exceed 30g. The vegetables and fruits include rotten vegetable leaves discarded in the vegetable market, damaged fruits, fruit peels and carrots. Wash the rotten vegetable leaves, throw away the rotten ones, cut them into slices, and cut the fruits and fruit peels after cleaning. Into blocks or flakes, wash the carrots and cut them into blocks, then mix the above raw materials and put them into a juicer to squeeze into vegetable and fruit juices. The bacterial ...

Embodiment 2

[0031] A microbial fermented pig feed, comprising the following raw materials in parts by weight: 30 parts of barley flour, 20 parts of bran powder, 25 parts of corn cob powder, 15 parts of beans, 10 parts of fish meal, 20 parts of potato flour, 20 parts of vegetables and fruits, 4 parts of sodium bicarbonate, 15 parts of bacterial liquid.

[0032] Its raw material processing method is with embodiment 1.

[0033] A preparation process of microbial fermented pig feed, the specific process steps are the same as in Example 1. The differences are: 1. Soak barley flour, bran powder, corncob powder, and beans in water for 36 hours; 2. Perform aerobic fermentation for 8 hours; Minutes, get sterilized fermented feed.

[0034] Obtain microbial fermentation pig feed product 2.

Embodiment 3

[0036] A microbial fermented pig feed, comprising the following raw materials in parts by weight: 25 parts of barley flour, 18 parts of bran powder, 22 parts of corn cob powder, 13 parts of bean dregs, 9 parts of fish meal, 18 parts of potato flour, 17 parts of vegetables and fruits, 3 parts of sodium bicarbonate, 12 parts of bacterial liquid.

[0037] Its raw material processing method is with embodiment 1.

[0038] A preparation process of microbial fermented pig feed, the specific process steps are the same as in Example 1. The differences are as follows: 1. Soak barley flour, bran powder, corncob powder, and beans in water for 30 hours; 2. Perform aerobic fermentation for 7 hours; Minutes, get sterilized fermented feed.

[0039] Obtain microbial fermentation pig feed product 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com