Low-temperature negative-pressure drying system for heat-sensitive materials

A heat-sensitive material, low-temperature negative pressure technology, used in evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of large temperature difference affecting product quality, large heat energy consumption, and high operating costs, to facilitate mobile transportation and transfer, The effect of high evaporation efficiency and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

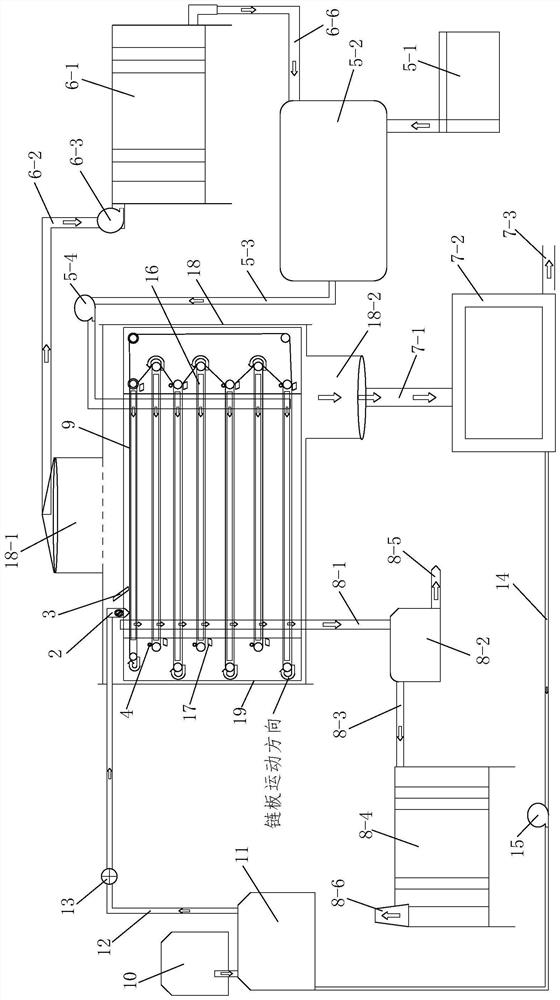

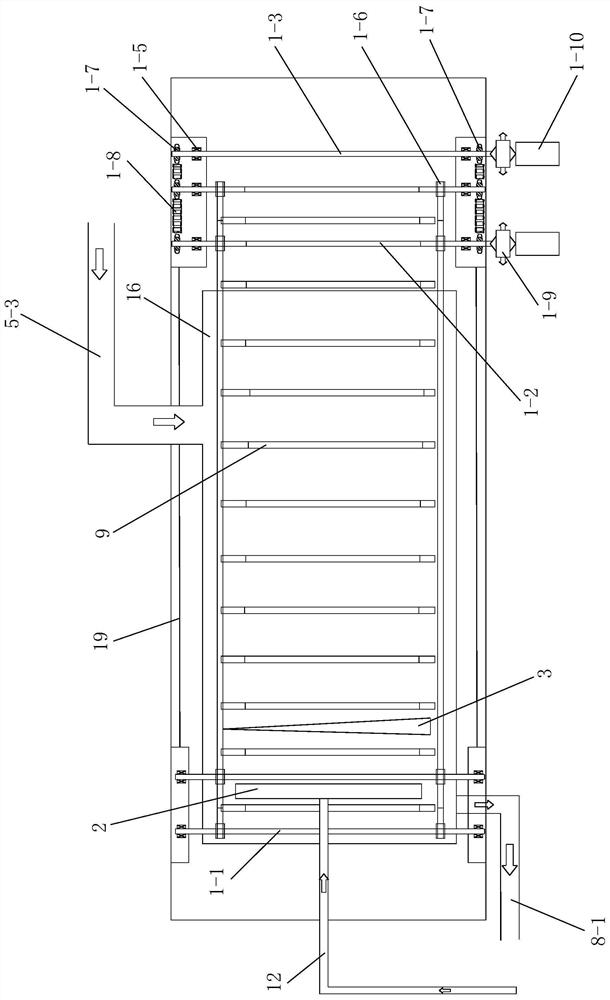

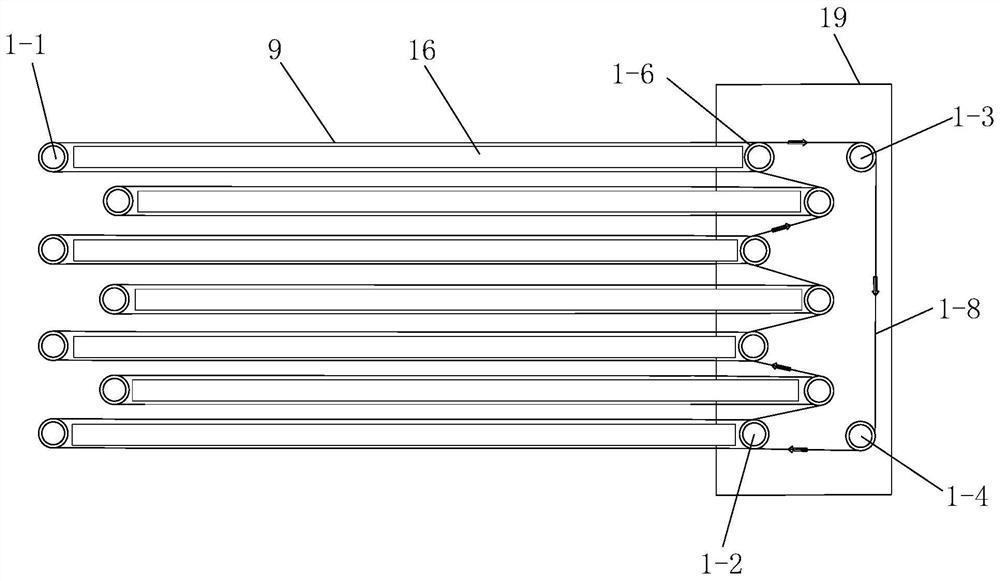

[0058] Such as figure 1 As shown, the present invention includes a pretreatment material collection pool 10, a preheating pool 11 for materials to be treated, a low-temperature negative pressure drying unit, a vapor compression system, a concentrated material treatment system, a heat exchange steam treatment system, and a steam scrubber system. The pre-treated material collection pool 10 is connected with the pre-treated material preheating pool 11 and the heat-sensitive material collected in the pre-treated material collection pool 10 is transported to the pre-treated material pre-heating pool 11 for preheating, and the pre-treated material is preheated The tank 11 is connected to the feed port of the low-temperature negative pressure drying unit through the feeding pipeline 12 and the feeding pump 13, and the preheated heat-sensitive material is sent into the low-temperature negative pressure drying unit under low-temperature negative pressure. For drying, the feeding pump 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com