Distributing device for full-body billet-textured porcelain plate and manufacturing method thereof

A cloth device and texture technology, which is applied in the field of cloth device for whole-body texture porcelain plates, can solve the needs of no whole-body texture, uneven material quantity, and inability to realize whole-body texture opening, edging, chamfering, paving, etc. problems, to achieve the effect of improving diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

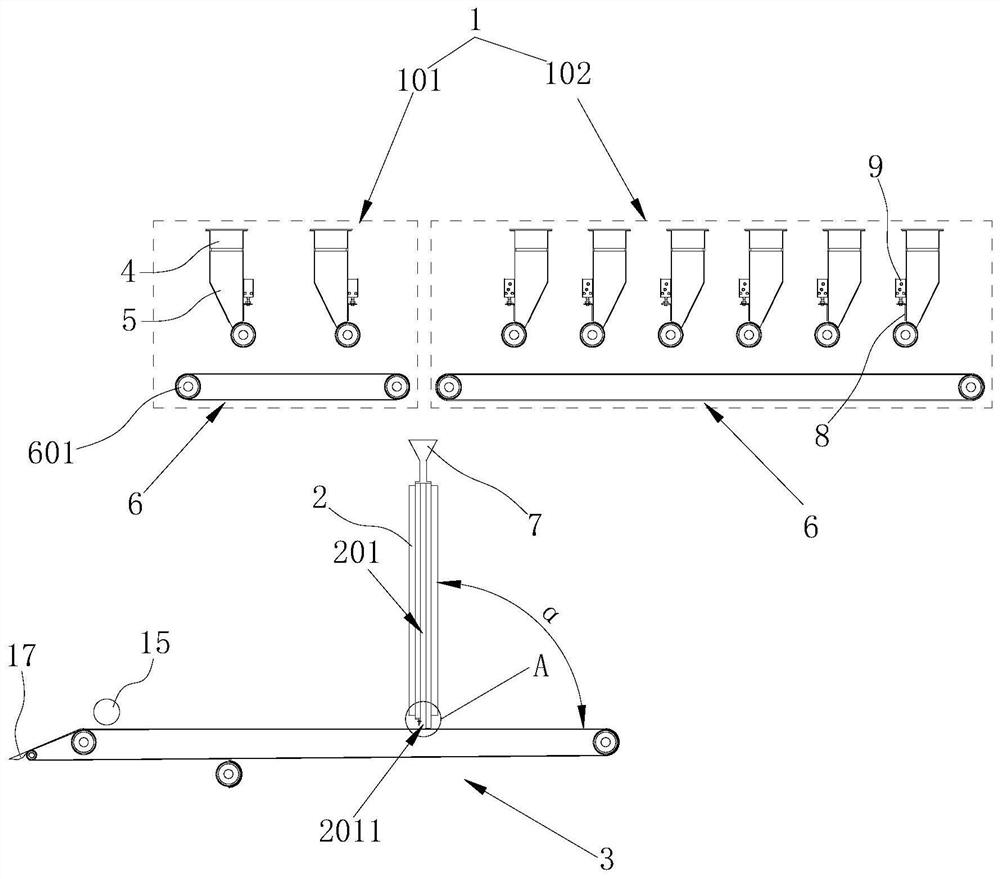

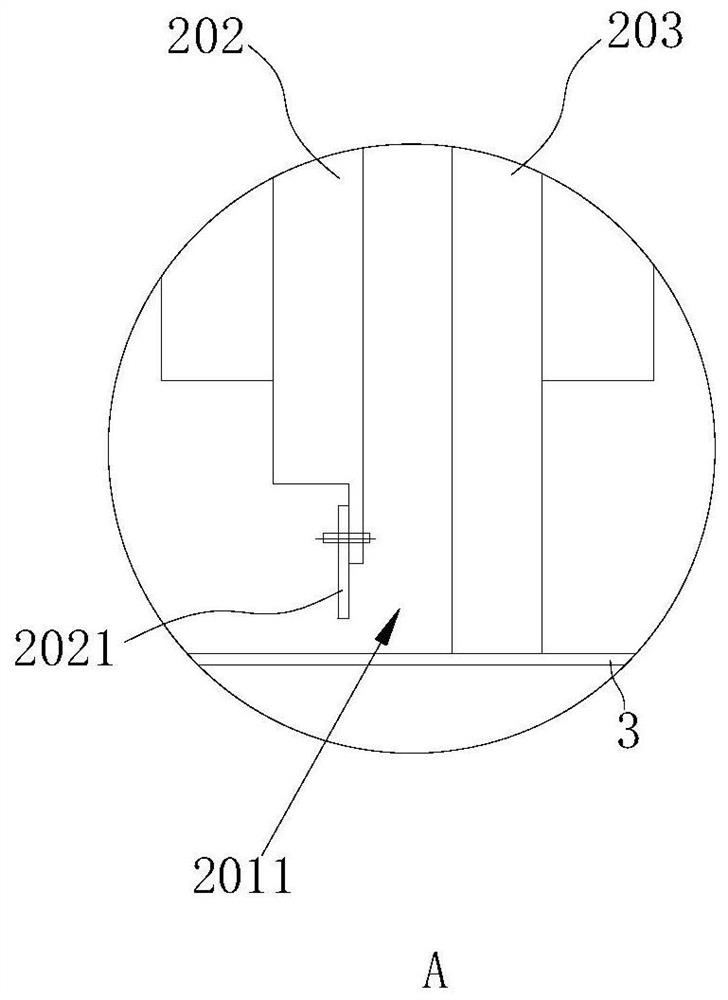

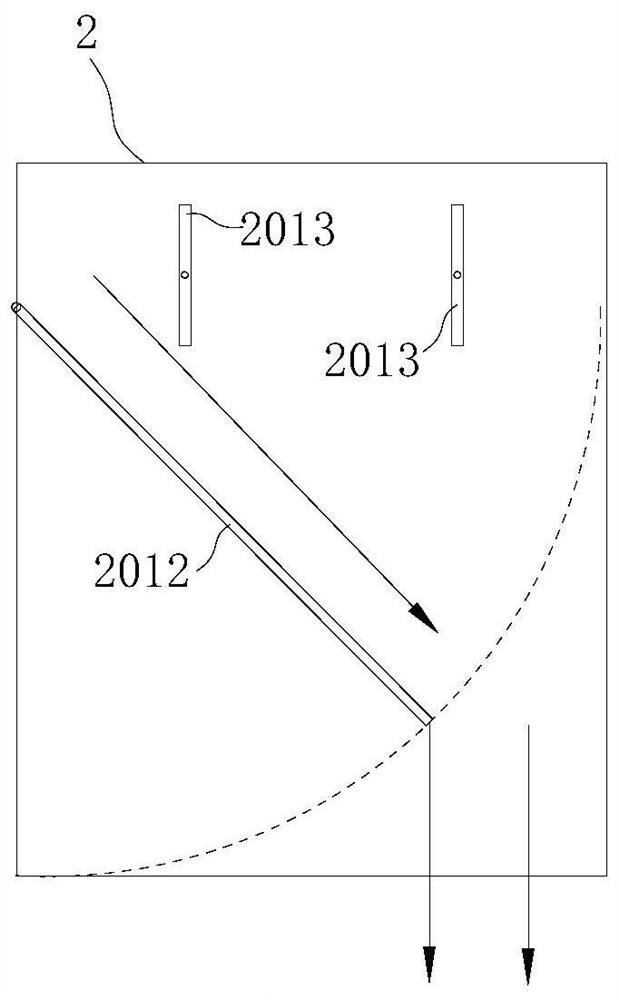

[0125] refer to figure 1 , figure 2 , Figure 4 , this embodiment discloses a distributing device for a whole-body textured porcelain plate, including a blanking assembly 1, a powder preforming box 2, and a belt conveying assembly 3. The belt conveying assembly 3 is commonly used in the prior art Conveyor belt, the belt conveying assembly 3 is horizontally arranged below the powder preforming box 2, the unloading assembly 1 is arranged above the powder preforming box 2, and the conveying plane between the powder preforming box 2 and the belt conveying assembly 3 Set as an included angle α, 61°≤α≤90°, α can be selected from 65°, 70°, 75°, 80°, 85°;

[0126] The powder preforming box 2 is provided with a material-filling cavity 201, the upper and lower ends of the material-filling cavity are provided with openings, and the lower end of the material-filling cavity is set with a discharge gate 2011;

[0127] The angle between the intersection line of the lower end of the powde...

Embodiment 2

[0154] refer to Figure 5 , this embodiment discloses a method for manufacturing a whole-body textured porcelain plate, including the distributing device for the whole-body textured porcelain plate in Example 1, and also includes a pressing machine 14 in the prior art:

[0155] Including the following processing steps:

[0156] a. Machine preparation: Assemble the conventional pressing machine 14 with the distributing device of the whole body textured porcelain plate of Embodiment 1 to form a ceramic tile production line. The line powder material blanking module 101 includes 2 rows of hoppers, and the texture powder material blanking The module 102 includes 6 rows of lowering hoppers. The lowering hoppers of the line powder material lowering module 101 and the texture powder material lowering module 102 are all set as flat roller lower hoppers, and five lower material hoppers are set under the storage part 4 of each lower hopper 5, five discharge baffles 8 are set correspondi...

Embodiment 3

[0175] This embodiment discloses another method for manufacturing a whole-body textured porcelain plate. Based on the above-mentioned embodiment, the difference between this embodiment and the above-mentioned embodiment lies in:

[0176] refer to Figure 8 , in the present embodiment, the discharge baffle plate 8 adopted at the outlet of the blanking part 5 is integrated, and is driven up and down by at least one driver 9, and several partitions 8 are arranged in the storage part 4 of each row of the discharge hopper. The storage part 4 is divided into multiple storage chambers 401 by the partition board 8, and by adjusting the position of the partition board 8 in the storage part 4, the cloth from the discharge port of the discharge part 5 can be adjusted to fall on the discharge conveyor belt 6 The raw material width above, wherein, in this embodiment, three partitions are arranged in the storage part 4 in the line powder material unloading module 101, and the storage part 4 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com