A kind of lens and processing method thereof

A processing method and lens technology, applied in packaging, instruments, optics, etc., can solve the problems of the protective film not fully covering the lens, increase the amount of protective film, and increase the processing cost, so as to improve the lens yield and prevent dust. Effect, effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

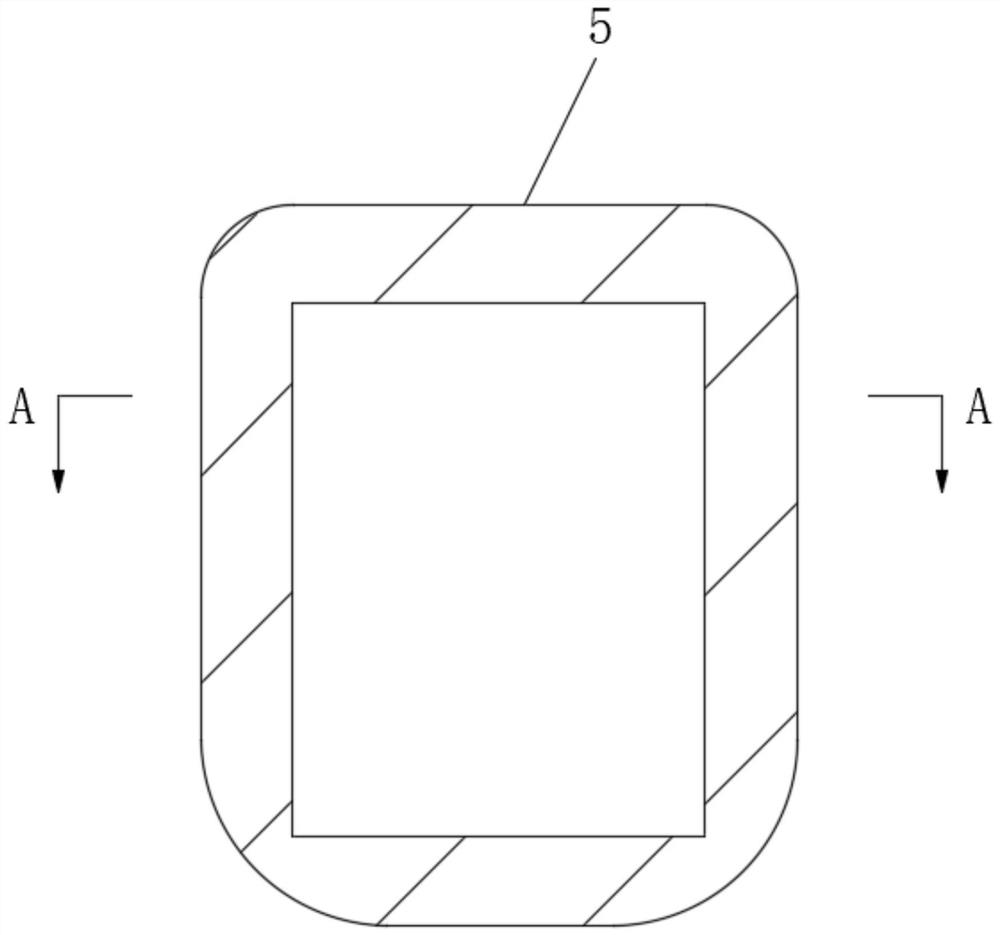

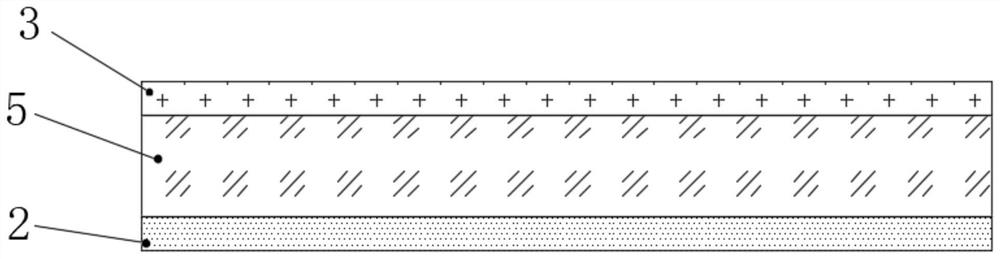

[0043] Such as Figure 1-2As shown, a lens includes a lens body 5, a first protective film 2 attached to the back of the lens body 5, and a second protective film 3 attached to the front of the lens body 5, and the first protective film 2 is close to the lens Acrylic glue is adhered to one side of the body 5 and the side of the second protective film 3 close to the lens body 5 .

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is:

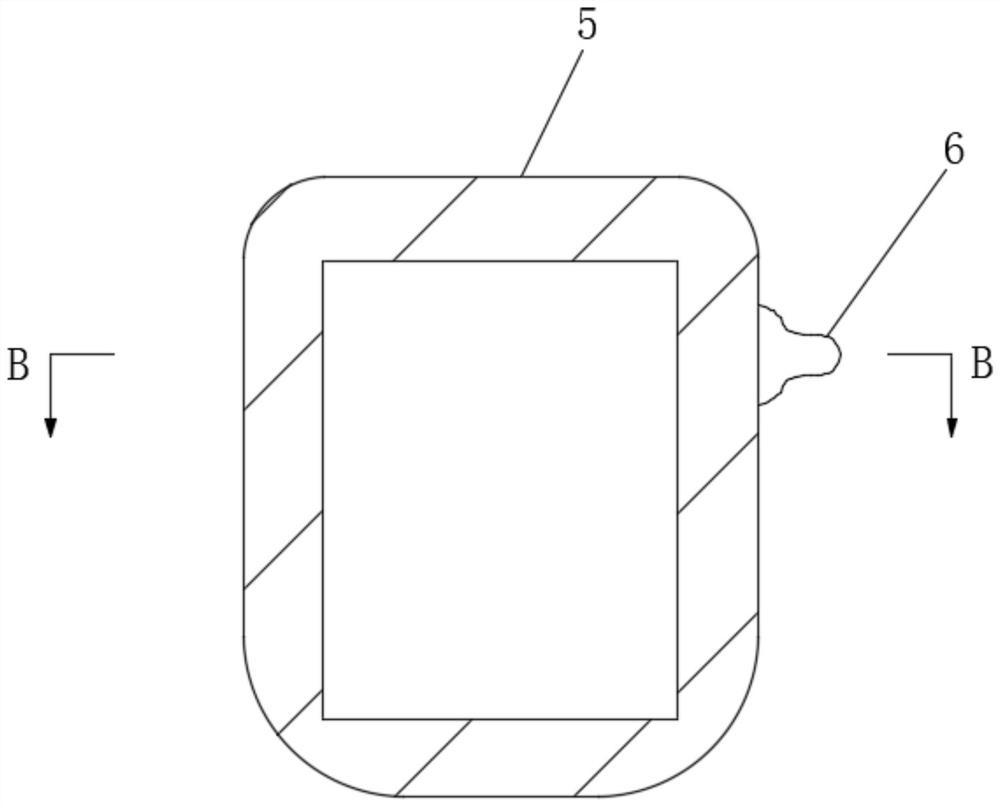

[0046] Such as Figure 3-4 As shown, the second protective film 3 is pasted with a handle portion 6 .

[0047] The handle part 6 includes a primer layer 61 and a PET film 62 bonded to the primer layer 61, the PET film 62 protrudes from the second protective film 3, and the primer layer 61 is sandwiched between the Between the PET film 62 and the second protective film 3 .

Embodiment 3

[0049] Such as figure 1 , 2 , shown in 5, a kind of processing method of eyeglass, comprises the steps:

[0050] (S1), take forming plate 1, set aside;

[0051] (S2), attaching the first protective film 2 to the front and back sides of the formed plate 1;

[0052] (S3), tear off the first protective film 2 on the front of the forming plate 1, and then attach the second protective film 3 and the third protective film on the front of the forming plate 1 in sequence;

[0053] (S4), positioning holes 4 are drilled on both sides of the raw material plate in step (S3), and then the formed plate 1 in step (S3) is CNC cut to form a plurality of evenly distributed semi-finished products;

[0054] (S5), after washing and drying the semi-finished product, tear off the third protective film to obtain the lens.

[0055] The forming sheet 1 is formed by ink printing on the raw sheet according to the layout design, and then drying;

[0056] Wherein, the raw material plate is PMMA plate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com