A kind of transition metal aluminum hydride and preparation method thereof

A technology of aluminum hydrides and transition metals, applied in the field of new transition metal aluminum hydrides and their preparation, can solve the problems of low reversible hydrogen storage capacity and difficulty in reaching the target, and achieve high hydrogen storage capacity, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

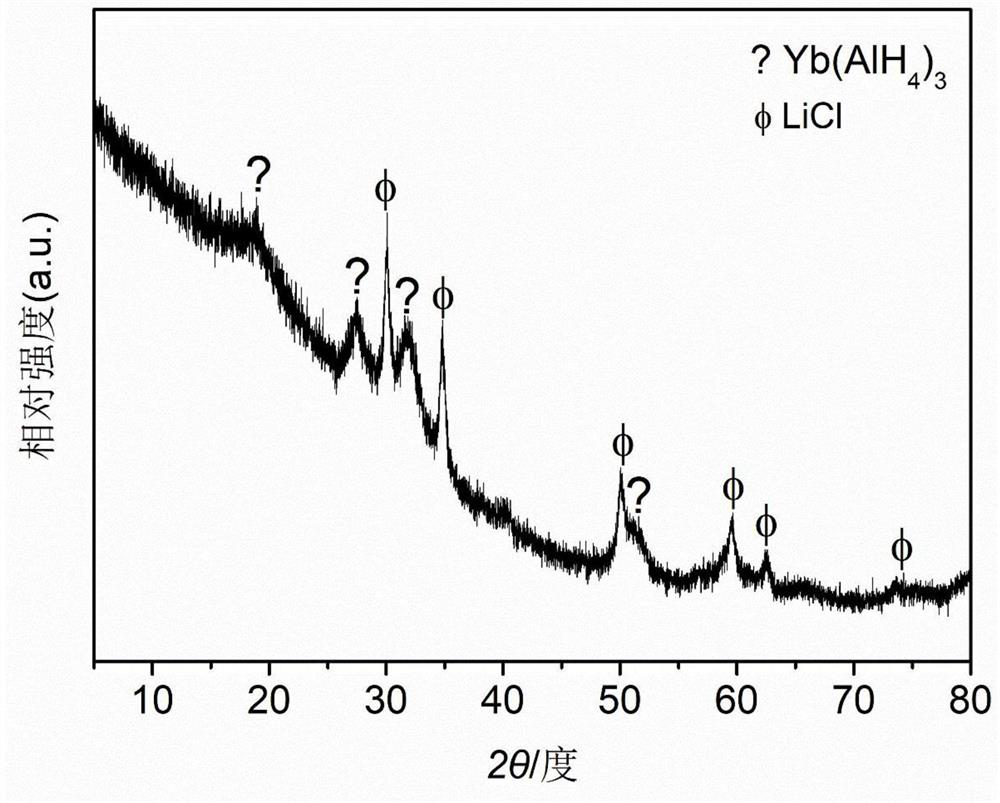

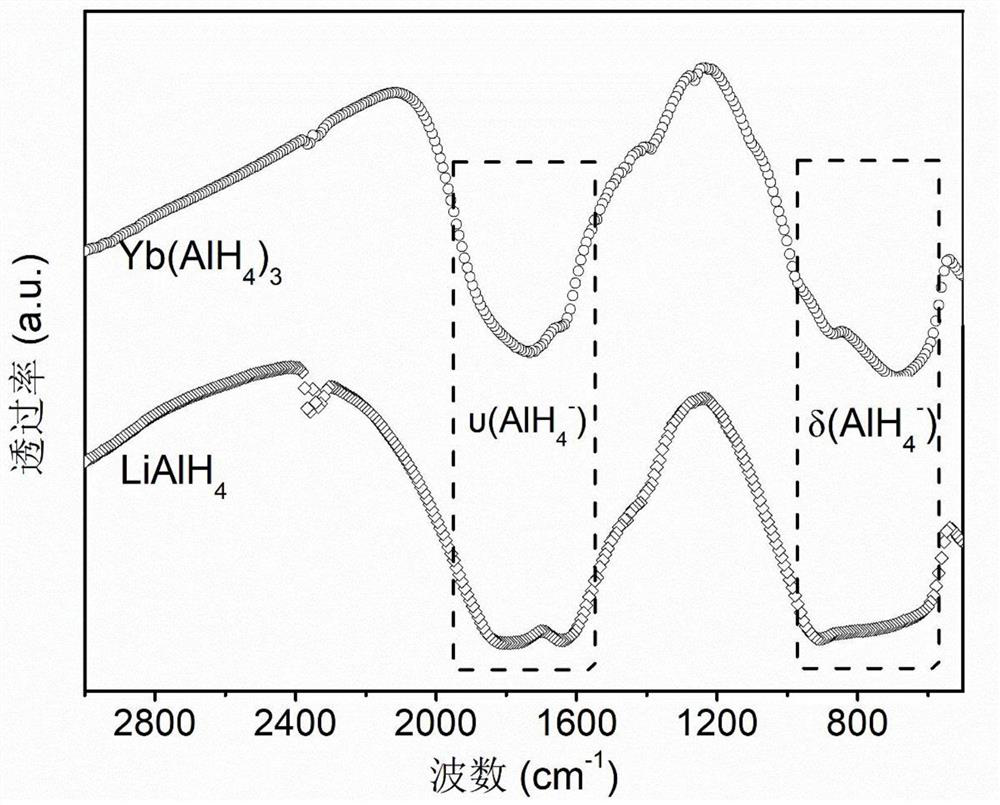

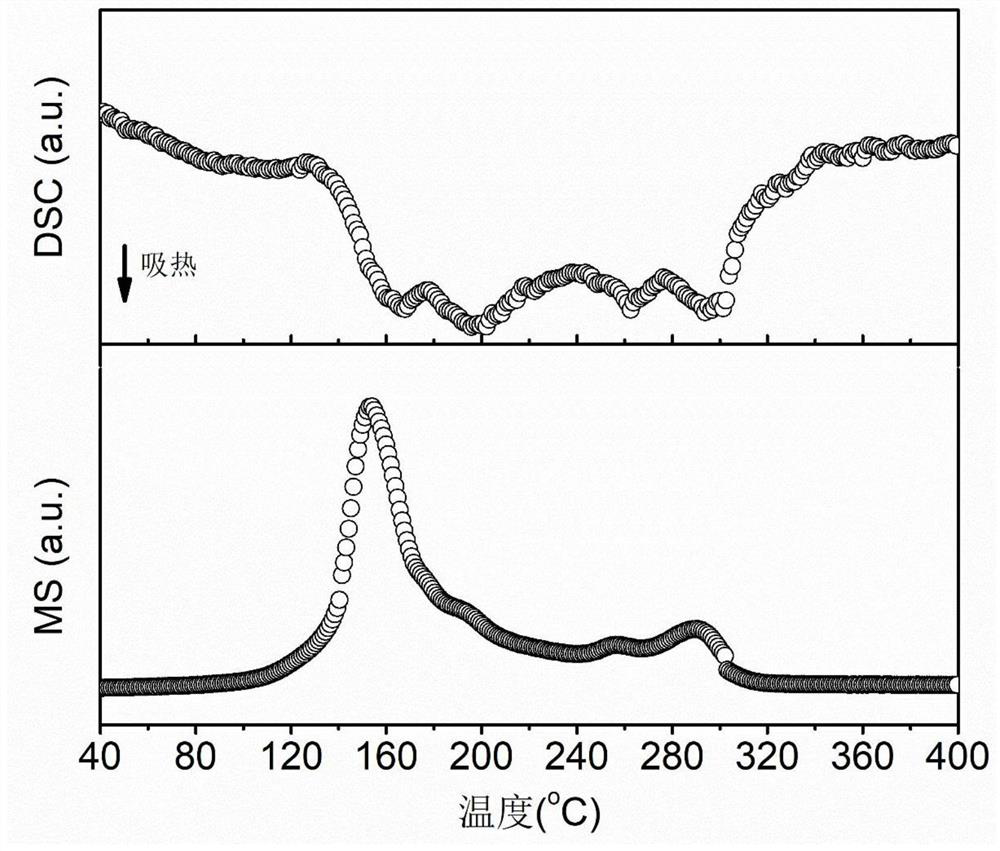

Embodiment 1

[0031] In a glove box protected by an argon atmosphere, the YbCl 3 and LiAlH 4 After mixing according to the molar ratio of 1:3, it was put into the ball mill tank together with stainless steel balls, and the ball-to-material ratio was 40:1; the gas in the ball mill tank was pumped out with a vacuum pump and then filled with hydrogen. This process was repeated three times, and then filled with 5 MPa put the hydrogen-charged ball mill into the planetary ball mill, the program is to stop for 10 minutes after each 30 minutes of ball milling, and to obtain Yb (AlH) after 4 hours of ball milling. 4 ) 3 .

Embodiment 2

[0033] In a glove box protected by an argon atmosphere, the YbCl 3 and LiAlH 4 After mixing according to the molar ratio of 1:3, it was put into the ball mill tank together with stainless steel balls, and the ball-to-material ratio was 40:1; the gas in the ball mill tank was pumped out with a vacuum pump and then filled with hydrogen. This process was repeated three times, and then filled with 8 MPa put the hydrogen-charged ball mill into the planetary ball mill, the program is to stop for 10 minutes after each 30 minutes of ball milling, and to obtain Yb (AlH) after 4 hours of ball milling. 4 ) 3 .

Embodiment 3

[0035] In a glove box protected by an argon atmosphere, the YbCl 3 and LiAlH 4 After mixing according to the molar ratio of 1:3, it was put into the ball mill tank together with stainless steel balls, and the ball-to-material ratio was 40:1; the gas in the ball mill tank was pumped out with a vacuum pump and then filled with hydrogen. This process was repeated three times, and then filled with 10 MPa put the hydrogen-charged ball mill into the planetary ball mill, the program is to stop for 10 minutes after each 30 minutes of ball milling, and to obtain Yb (AlH) after 4 hours of ball milling. 4 ) 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com