A kind of 300mpa level hot-rolled smooth round refractory steel bar and its manufacturing method

A manufacturing method and 300mpa technology, applied in the direction of improving process efficiency, can solve the problems of reduced yield strength, inability to meet the fire resistance of buildings, etc., to improve high temperature strength, improve high temperature oxidation resistance and creep resistance, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

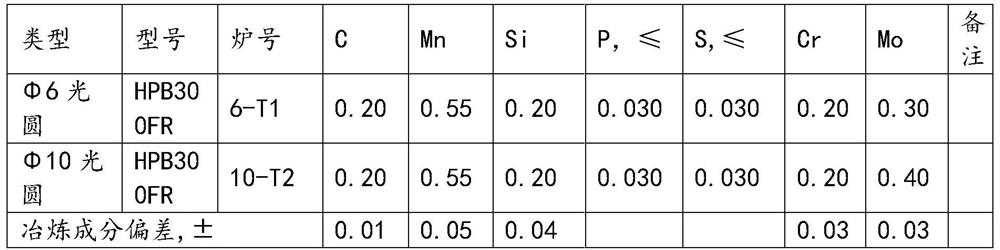

[0027] The invention provides a 300MPa level hot-rolled round refractory steel bar, the weight percentage and chemical composition of which are: C: 0.16%-0.22%, Si: 0.20%-0.50%, Mn: 0.30%-0.60%, P: ≤ 0.03%, S: ≤0.03%, Cr: ≤0.35%, Mo: 0.20%-0.40%, and the balance is Fe and unavoidable residual elements.

[0028] A kind of manufacturing method of described a kind of 300MPa grade hot-rolled smooth round refractory steel bar, it comprises the steps:

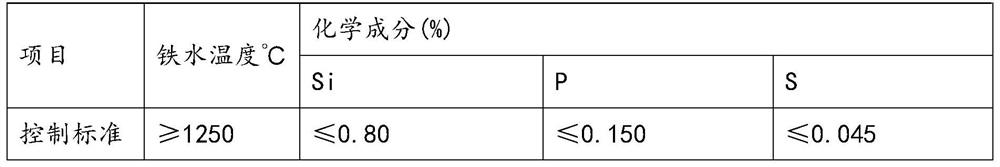

[0029] S1: molten steel smelting

[0030] Smelting molten iron and / or scrap steel through a converter or electric furnace to obtain molten steel; when the conditions are met: the temperature is 1670°C to 1680°C, the mass fraction of C is ≤0.06%, the mass fraction of P is ≤0.02%, and the content of sulfur The mass fraction is ≤0.025%, and the steel is tapped; when the steel is tapped, Si iron, Mn iron, Si-Mn alloy, Cr iron, and Mo iron are added. After the steel is tapped, according to the chemical composition of the 300MPa grade hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com