All-wool spinning pure natural anti-wrinkle fabric manufacturing method and equipment

A production method, a pure natural technology, applied in textiles, spinning machines, textiles and papermaking, etc., can solve the problems of low efficiency and environmental protection, and achieve the effects of high efficiency, energy saving and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

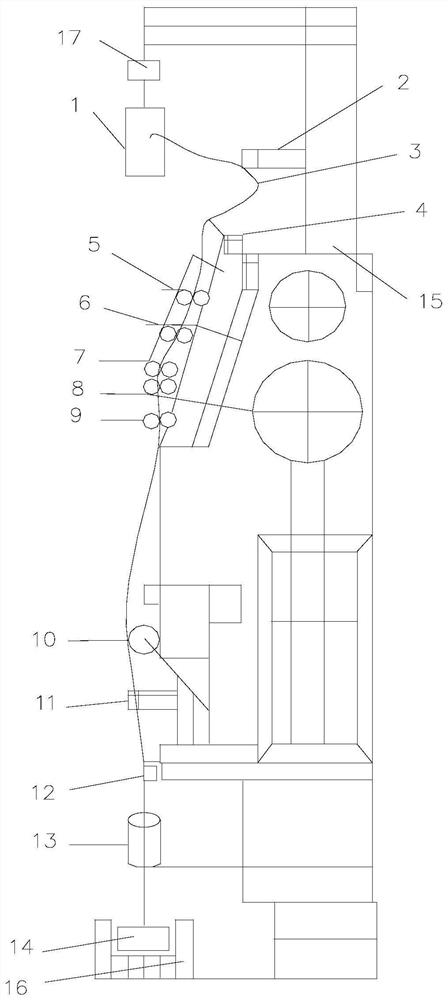

Image

Examples

Embodiment 1

[0023] A method for making all-wool worsted pure natural anti-wrinkle fabrics. Two strands of roving are suspended from the spindle, automatically fed from the VIP spinning can, bypassing the yarn guide rod, and transported to the working group of the VIP spinning machine. The balance tension is controlled by the tension sheet. After the roving is divided into two strands by the yarn splitter, it enters the drafting device area of the Vipp spinning machine, enters the drafting system through the rear top roller, and then introduces it into the front top roller through the middle top roller, and outputs from the front top roller The sliver enters the friction motion through the friction roller, and adds a certain false twist to the yarn to make it have a certain strength. The length of the twisting zone is 110mm; The thread is cleaned, and then enters the tension groove through the large guide wheel, and then enters the yarn clearer to clear the yarn after passing through the ...

Embodiment 2

[0025] The manufacturing method of a kind of all-wool worsted pure natural wrinkle-resistant fabric described in embodiment 1, the initial speed of the precision bobbin is 20m / min; in the acceleration of the precision bobbin, the driving acceleration time is 3.8S, and the output speed of the front roller is 180m / min; in the precision bobbin deceleration, the deceleration time is 1.7S; in the yarn drafting process, the drafting multiple is 25 times; in the yarn twisting, the friction roller gear is 4 levels, and the friction roller traverse speed is 22mm / s; in yarn plying, the gauge of the guide wheel group is 90mm; in yarn clearing, the drafting ratio of raw head is 60% of the total drafting ratio; in yarn winding, the tension compensation length is 52mm, The twist shrinkage is 99%, and it is spun into a yarn with a metric count of 12-16 tex*2; the twist is 1100-1450T / M in the wrapping machine.

Embodiment 3

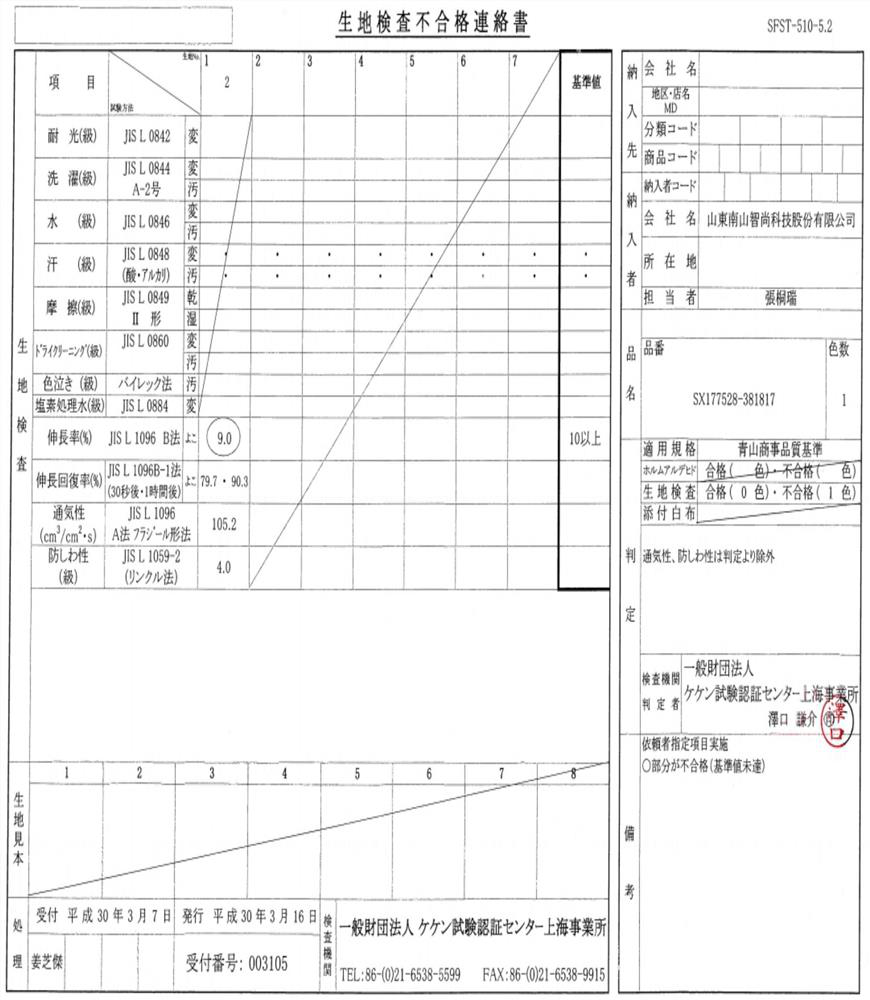

[0027] The manufacturing method of a kind of all-wool worsted pure natural wrinkle-resistant fabric described in embodiment 1, the initial speed of the precision bobbin is 20m / min; in the acceleration of the precision bobbin, the driving acceleration time is 3.8S, and the output speed of the front roller is 180m / min; in the precision bobbin deceleration, the deceleration time is 1.7S; in the yarn drafting process, the drafting multiple is 25 times; in the yarn twisting, the friction roller gear is 4 levels, and the friction roller traverse speed is 22mm / s; in yarn plying, the gauge of the guide wheel group is 90mm; in yarn clearing, the drafting ratio of raw head is 60% of the total drafting ratio; in yarn winding, the tension compensation length is 52mm, The twist shrinkage is 99%, and it is spun into a yarn with a metric count of 12 tex*2; the twisting degree is 1100T / M in the wrapping machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com