Wireless electromagnetic wave direct current control casing valve capable of relieving pressure

A radio and electrical control technology, applied in wellbore/well valve devices, wellbore/well components, earth-moving drilling, etc. The effect of reducing processing difficulty, high safety and reliability, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to following description:

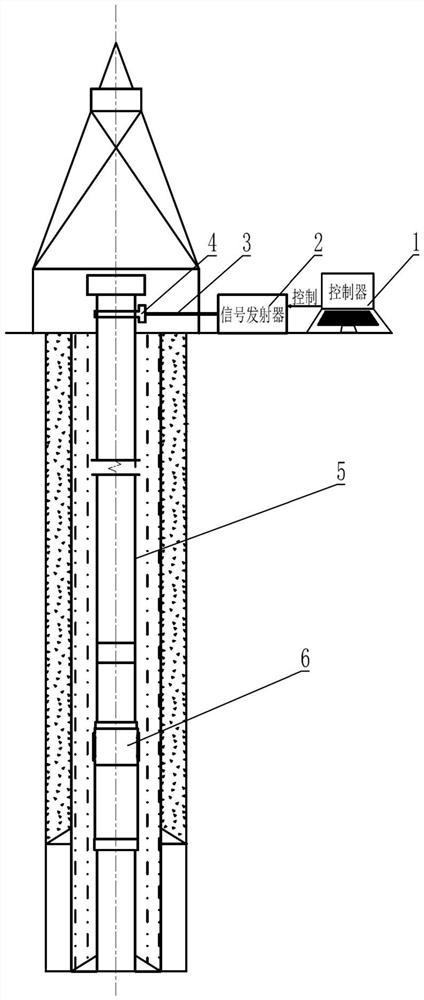

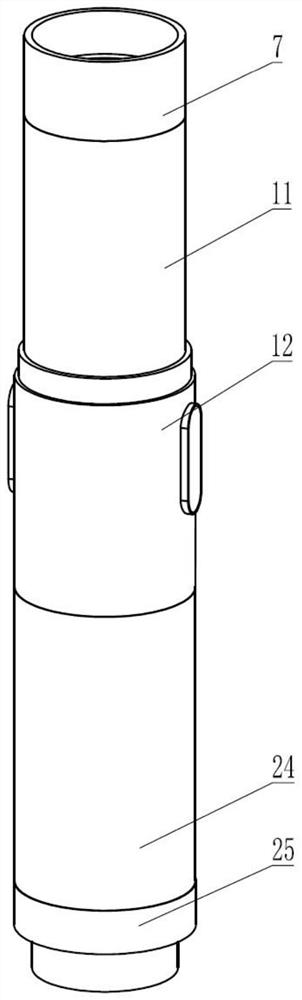

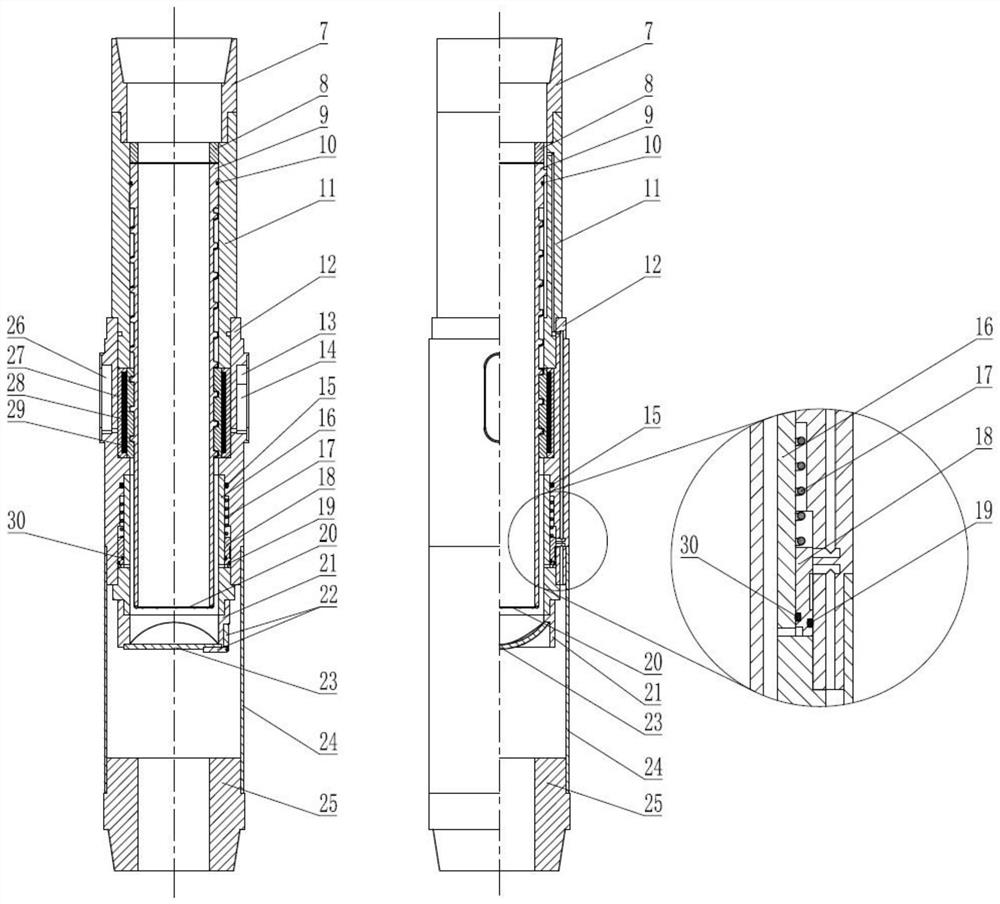

[0029] Such as Figure 1-Figure 11 As shown, a wireless electromagnetic wave direct control pressure relief sleeve valve consists of an upper joint 7, an upper outer shell 11 threadedly connected with the upper joint 7, a retaining ring 8 mounted on the upper outer shell 11 through threads, and The upper outer shell 11 is threadedly connected to the middle outer shell 12, the lower outer shell 24 is threaded to the middle outer shell 12, the lower joint 25 is threaded to the lower outer shell 24, installed on the upper outer shell 11 and the middle outer shell 12 is composed of a valve tongue switch mechanism, a bypass pressure relief mechanism and a wireless electromagnetic wave control system. It is characterized in that: a gas passage I1101 is set inside the upper outer shell 11, and a ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com