Watchcase and manufacturing method thereof

A manufacturing method and watch case technology, applied in the field of processing and manufacturing, can solve problems such as loss of marking features, wear, corrosion, etc., and achieve the effect of suppressing the flood of counterfeit products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

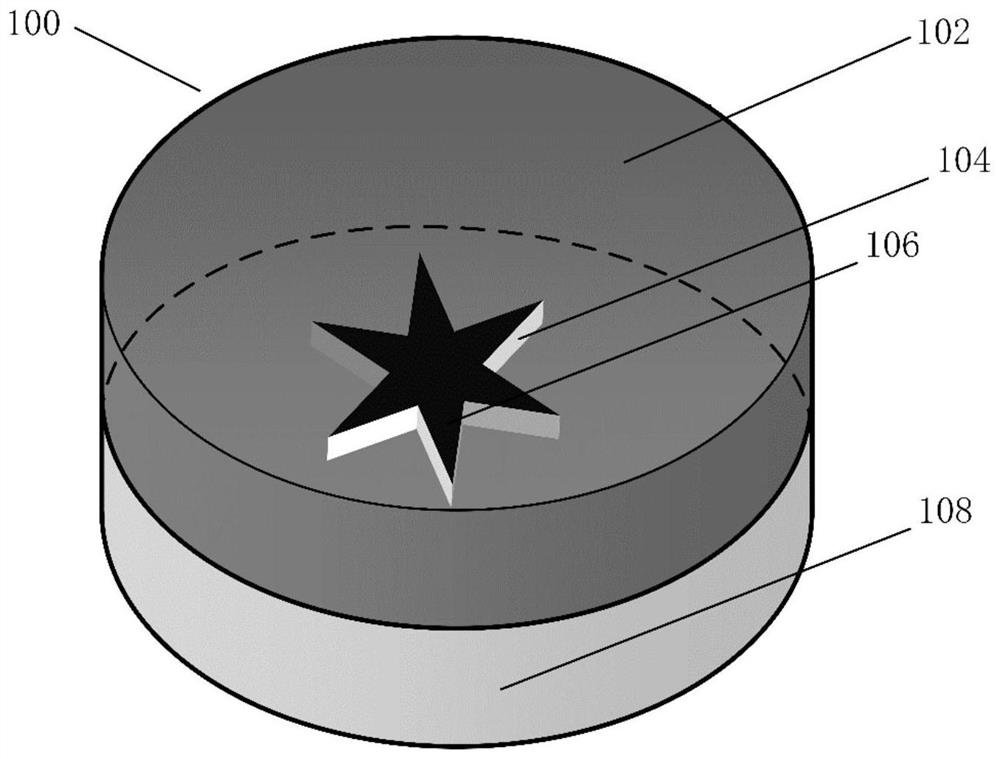

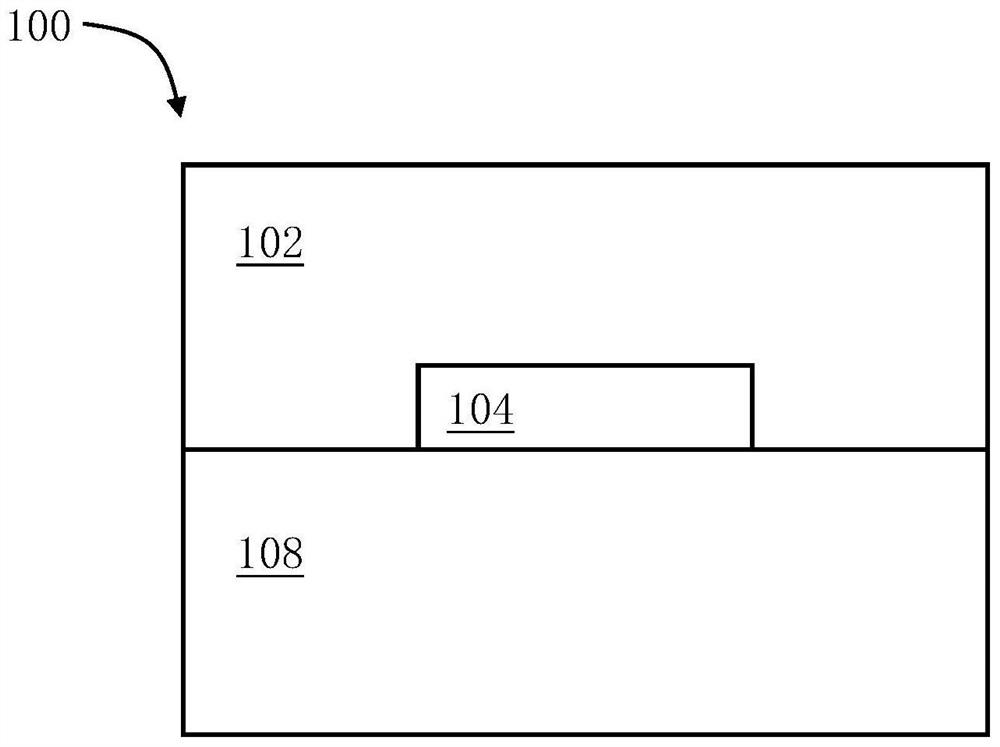

[0032] Using laser three-dimensional forming technology to prepare chassis material 316L stainless steel (density 7.98g / cm 3 ); at the center of the upper surface of the chassis material, a special cross-sectional shape (hexagonal star, such as figure 1 shown) marking material tungsten carbide (density 15.63g / cm 3 ), forming a hexagonal star tungsten carbide marking pattern; on the upper surface of the chassis material 316L and marking material tungsten carbide, 304L stainless steel (density 7.93g / cm 3 ) cover layer material, bury the marking pattern WC, and finally prepare a watch case with an embedded anti-counterfeiting pattern; due to the density difference between the marking material and the cover layer material, the pattern information can be detected by digital X-ray imaging technology, so as to obtain the watch case Shell brand, serial number, preparation materials, production time, ID information, transaction information, etc.

Embodiment 2

[0034] The chassis material 316L stainless steel (density 7.98g / cm 3 ); at the center of the upper surface of the chassis material, a special cross-sectional shape (hexagonal star, such as figure 1 Shown) marking material copper alloy Cu10Sn (density 8.00g / cm 3 ), forming a hexagonal star copper alloy marking pattern; on the upper surface of the chassis material 316L and the marking material copper alloy, Ni625 nickel-based alloy (density 8.4g / cm 3 ) cover layer material, bury the marking pattern copper alloy, and finally prepare a watch case with an embedded anti-counterfeiting pattern; due to the density difference between the marking material and the cover layer material, the pattern information can be detected by digital X-ray imaging technology, so as to obtain The brand, serial number, preparation material, production time, ID information, transaction information, etc. of the watch case.

Embodiment 3

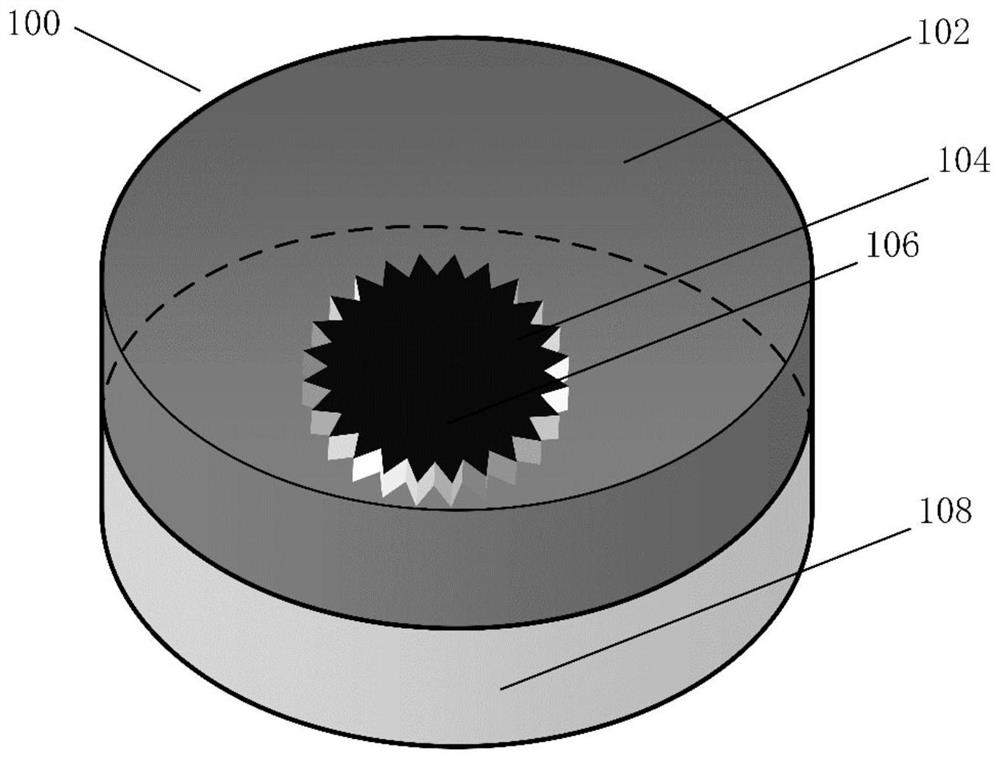

[0036] Using laser three-dimensional forming technology to prepare chassis material 304L stainless steel (density 7.93g / cm 3 ); at the center of the upper surface of the chassis material, a special cross-sectional shape (gear shape, such as figure 2 shown) marking material titanium carbide (density 4.96g / cm 3 ), forming a gear-shaped titanium carbide marking pattern; on the upper surface of the chassis material 304L stainless steel and marking material titanium carbide, 316L stainless steel (density 7.98g / cm 3 ) cover layer material, bury the marking pattern titanium carbide, and finally prepare a watch case with an embedded anti-counterfeiting pattern; due to the density difference between the marking material and the cover layer material, the pattern information can be detected by digital X-ray imaging technology, so as to obtain The brand, serial number, preparation material, production time, ID information, transaction information, etc. of the watch case.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com