Capacitance defect detection method based on machine vision

A defect detection and machine vision technology, applied in the direction of optical testing defects/defects, instruments, measuring devices, etc., can solve the problems of restricting the production of enterprises, low detection efficiency, slow detection speed, etc., to ensure consistency, reliability and reliability. The effect of high accuracy and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

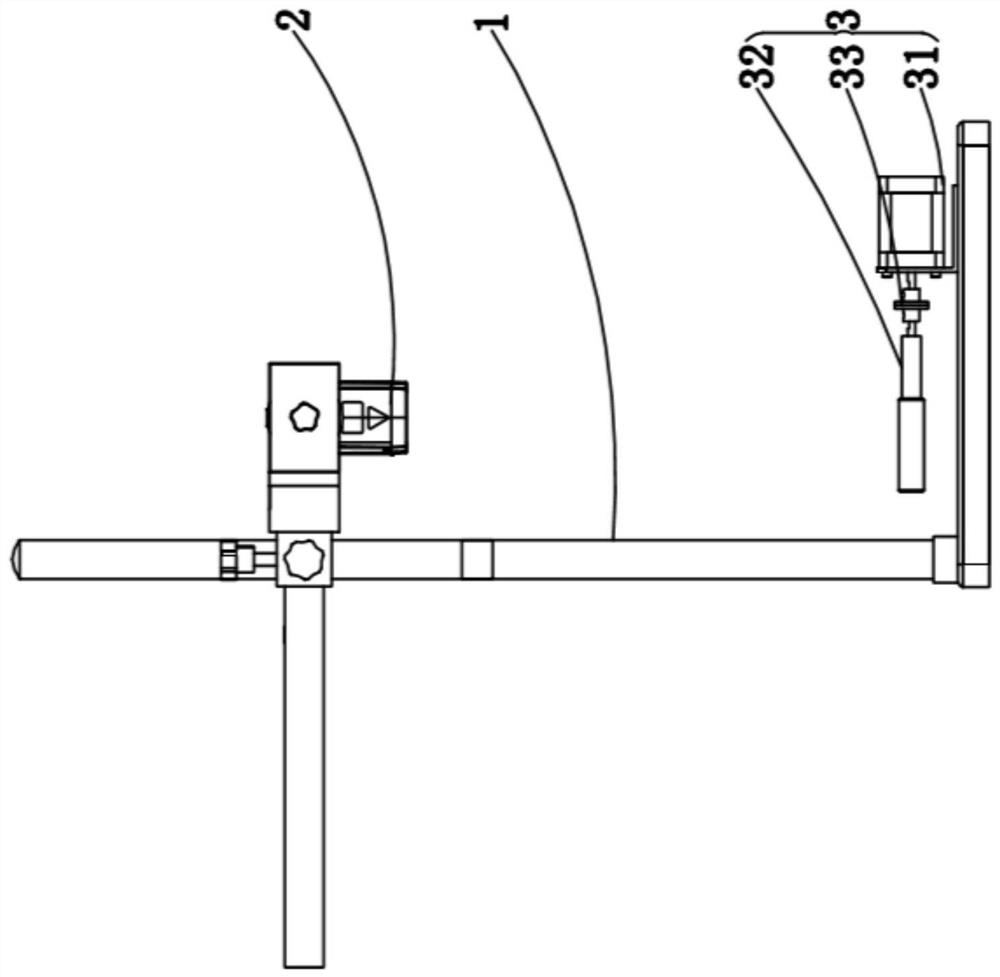

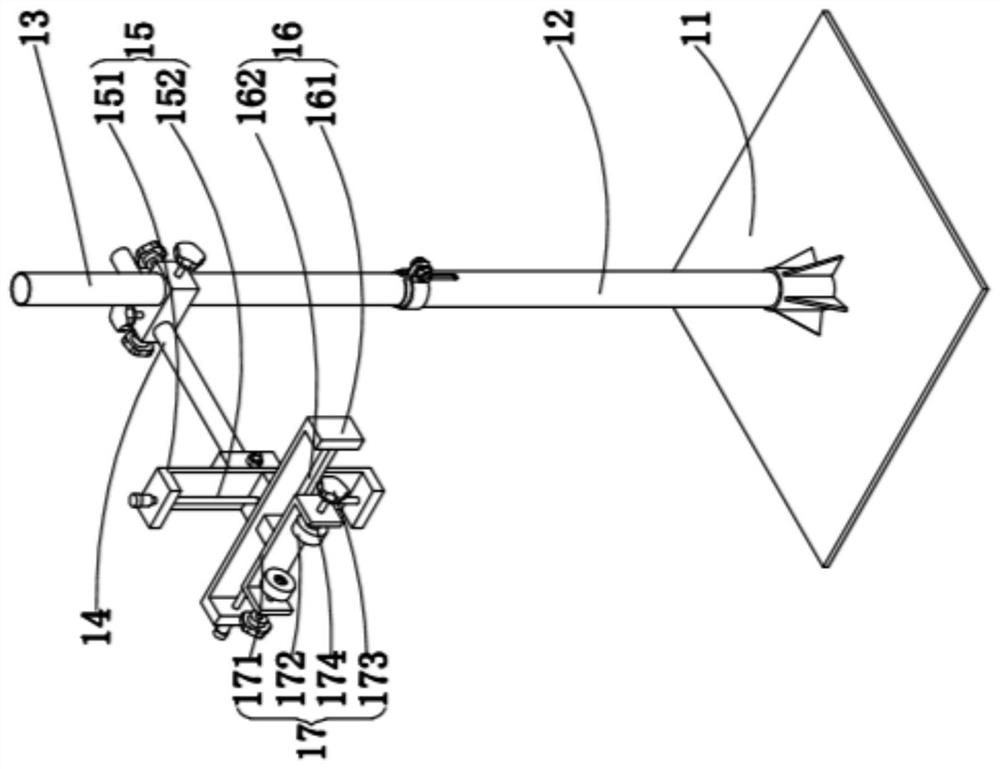

[0057] see Figure 1 to Figure 3 , figure 1 It is a schematic structural diagram of the machine vision-based capacitive defect detection device of this embodiment; figure 2 It is a structural schematic diagram of the camera bracket of the capacitive defect detection device based on machine vision in this embodiment; image 3It is a structural schematic diagram of the capacitance fixture of this embodiment. As shown in the figure, this embodiment provides a defect detection device. The defect detection device of this embodiment includes an image acquisition system, a motion control system and a defect detection system. The image acquisition system includes a camera bracket 1, a laser camera 2 and a computer ( Not shown in the figure), the camera bracket 1 is used to fix the laser camera 2, and the laser camera 2 is used to collect the image data of the capacitor to be detected and transmit the image data to the computer. The image data taken include height map and depth map;...

Embodiment 2

[0068] see Figure 4 , Figure 4 It is a flow chart of the detection method of this embodiment. As shown in the figure, the defect detection method based on machine vision adopts the defect detection device described in Embodiment 1, and the specific detection method is as follows:

[0069] Step A. Image Data Acquisition:

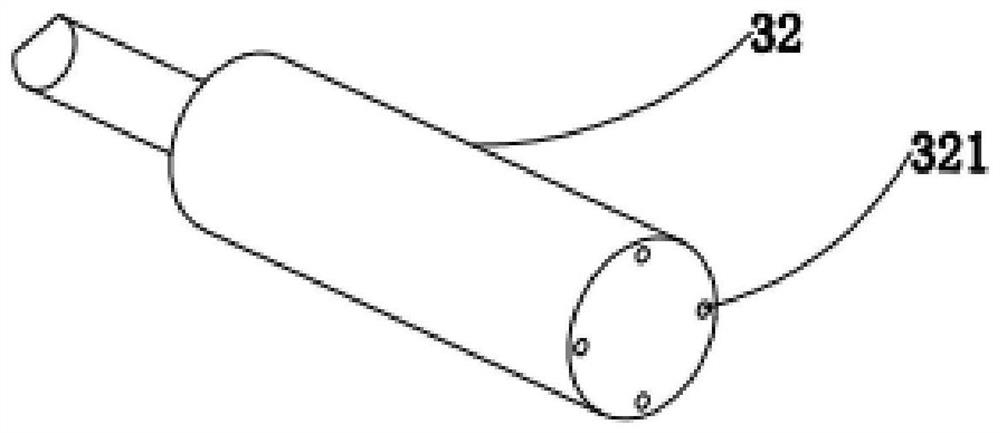

[0070] Fix the capacitor to the motion control system: insert the electrode of the capacitor to be detected into the opening 321 of the capacitor fixture 32, so that the capacitor fixture 32 fixes the capacitor to be detected;

[0071] Motion control system rotation capacitor: the motion control card controls the rotation of the stepper motor 31, and the motion control card sends a rotation pulse signal to the stepper driver. When the stepper driver receives the rotation pulse signal from the motion control card, it will drive the stepper motor 31 rotates one revolution, thereby driving the capacitor to rotate one revolution;

[0072] The image acquisit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com