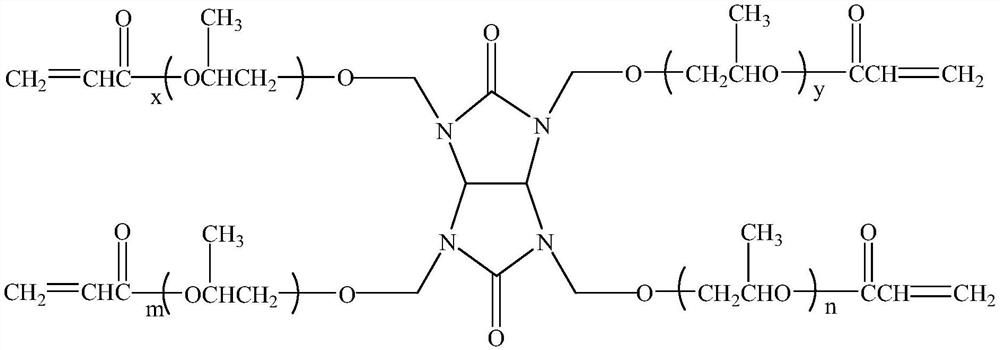

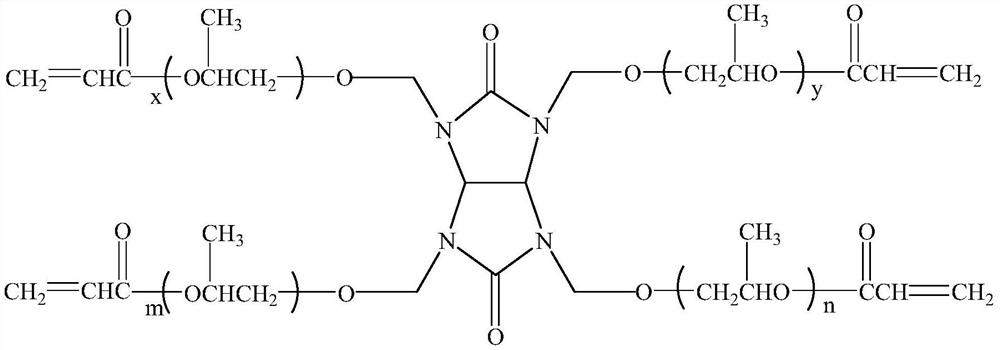

Acryloyloxy-terminated polyether curing agent

A technology of acryloyloxypolyether, acryloyloxypolypropylene oxide methyl glycoluril, applied in the direction of polyether adhesive, adhesive, adhesive type, etc., can solve the problem of propellant safety and reliability problems such as decline, impact on mechanical properties, and decrease in propellant density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Synthesis of 1,3,4,6-tetrahydroxypolypropylene oxide methyl glycoluril

[0032] In a four-neck round bottom flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, add 2.62g (0.01mol) of 1,3,4,6-tetramethylol glycoluril and 20mL of CH 2 Cl 2 , add 0.85g (0.006mol) boron trifluoride · diethyl ether complex under stirring, continue to stir for 30min and start to slowly add 11.62g (0.2mol) of propylene oxide dropwise, continue to react for 24h after the dropwise addition, and then add 2 %Na 2 CO 3 20 mL of aqueous solution was used to terminate the reaction, and the organic phase was separated with a separatory funnel, washed with water until neutral, and concentrated under reduced pressure to obtain a light yellow viscous liquid.

[0033] Structure Identification:

[0034] IR, ν max (cm -1 ): 3443(-OH), 2966, 2847(-CH 3 ,-CH 2 ), 1700, 1300 (glycoluril ring), 1112 (C-O-C).

[0035] Molecular weight and distribution:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com