Cellulose solution and method of dissolving cellulose

A cellulose solution and cellulose technology, applied in the field of cellulose, can solve the problems of long dissolution time, harsh conditions and high cost, and achieve the effects of short dissolution time, easy operation and convenient dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

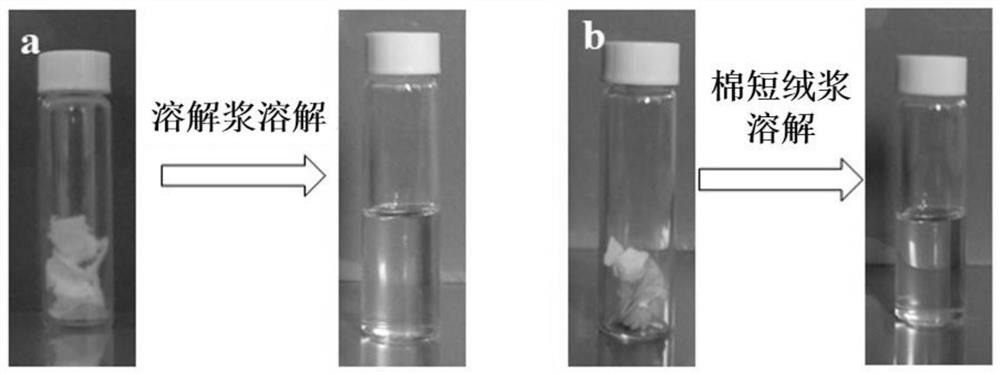

[0029] Weigh the dissolving pulp (viscosity-average molecular weight M η =8.0×10 4 ) 0.1 g, add 20 g of water at 20° C., then add 79.8 g of 1.5 M benzyltriethylammonium hydroxide aqueous solution at 10° C., and stir for 0.5 minutes to obtain a transparent cellulose solution. The content of cellulose in the gained cellulose solution is 0.1wt%, as figure 1 Shown in a.

Embodiment 2

[0031] Weigh the dissolving pulp (viscosity-average molecular weight M η =8.0×10 4 ) 4 grams, add 30 grams of water at 0°C, then add 66 grams of 15°C 2.0M benzyltrimethylammonium hydroxide / benzyltriethylammonium hydroxide aqueous solution, and stir for 5 minutes to obtain a transparent cellulose solution . The content of cellulose in the obtained cellulose solution was 4 wt%.

Embodiment 3

[0033] Weigh the dissolving pulp (viscosity-average molecular weight M η =8.0×10 4 ) 0.1 g, was added into 99.8 g of 20° C. 0.5 M benzyltriethylammonium hydroxide aqueous solution, because the concentration of benzyltriethylammonium hydroxide was too low, stirring for 5 minutes did not completely dissolve the cellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com