Black-edge-covering bright white paint

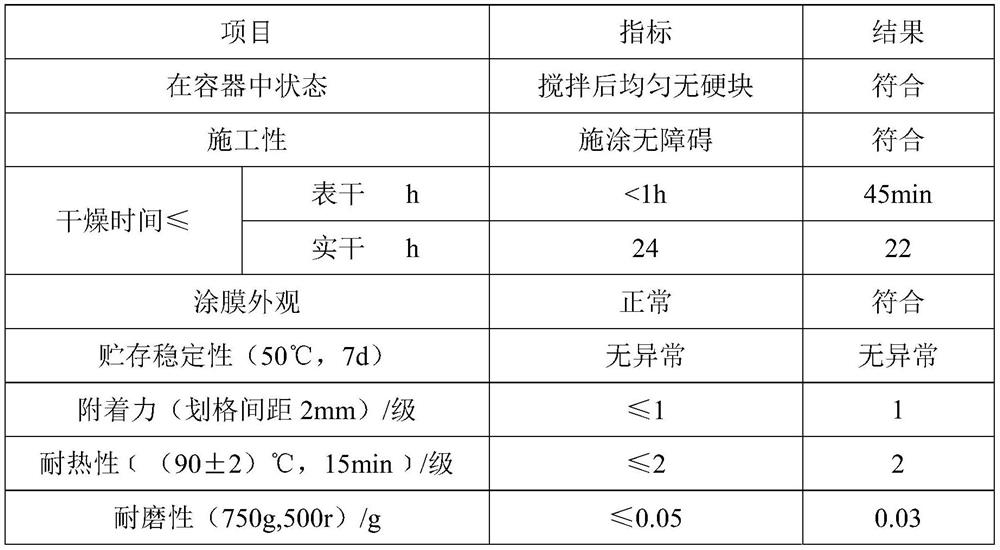

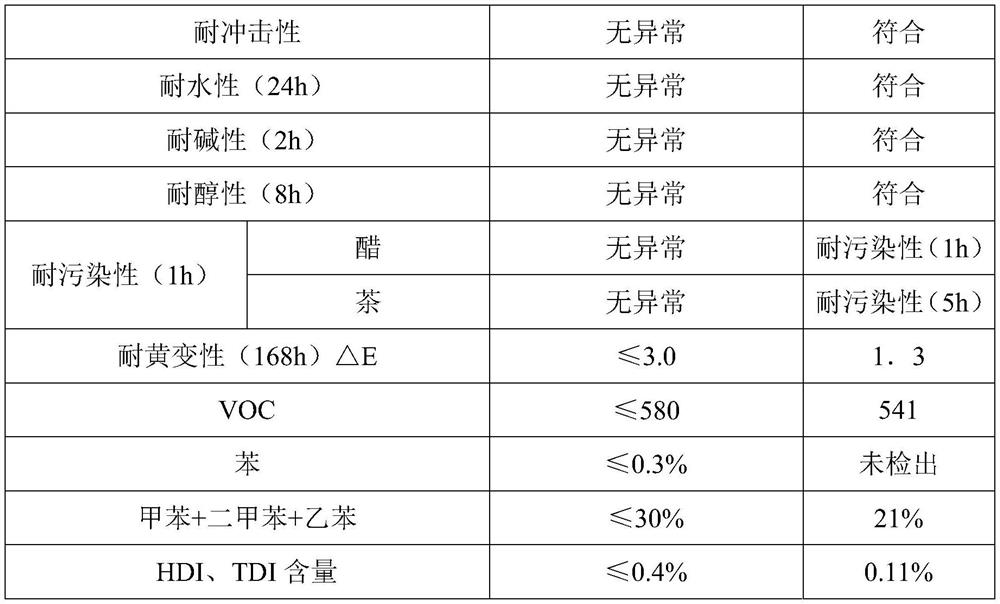

A bright light and coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as coating sag, and achieve the effects of excellent adhesion, strong sag resistance, and good hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the first component of the embodiment of the present invention is as follows:

[0023] Step 1: Mix synthetic fatty acid resin, vegetable oleic acid resin, acrylic resin, and dispersant, and disperse at a medium speed for 10-15 minutes until fully uniform, with a viscosity of 5000±500CPS / 25°C;

[0024] Step 2: Add silicon dioxide and pigments to the mixed solution obtained in step 1 and disperse them evenly;

[0025] Step 3: Add leveling agent and 0.8 to 1 part by weight of defoamer to the mixed liquid obtained in Step 2 and disperse evenly;

[0026] Step 4: Add the remaining defoamer to the mixture obtained in Step 3 and disperse evenly until the fineness is ≤20um, and the viscosity is controlled at 5000±500CPS / 25°C.

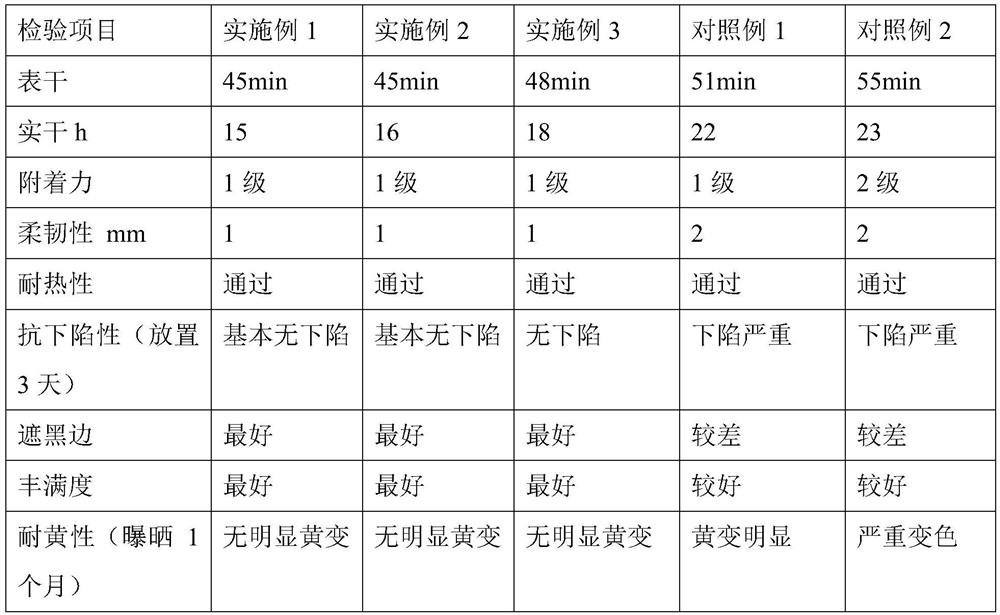

Embodiment 1

[0028] Component A of the embodiment of the present invention is composed of the following raw materials by weight: 34 to 48 parts by weight of synthetic fatty acid resin, 10 parts by weight of vegetable oleic acid resin, 5 parts by weight of acrylic resin, 0.5 parts by weight of silicon dioxide, 37 parts by weight of pigment, disperse 0.2 parts by weight of agent, 0.5 parts by weight of leveling agent, and 1.8 parts by weight of defoamer, wherein the leveling agent consists of 0.1 parts by weight of EFKA3600, 0.3 parts by weight of EFKA-3777, and 0.1 parts by weight of TEGO 450.

[0029] Component B of the embodiment of the present invention consists of the following raw materials in parts by weight: 30 parts by weight of butyl acetate, 15 parts by weight of TDI trimer, 30 parts by weight of TDI-TMP adduct, and 250 parts by weight of HDI trimer.

[0030] Component C of the embodiment of the present invention consists of the following raw materials in parts by weight: 50 parts ...

Embodiment 2

[0033] Component A of the embodiment of the present invention consists of the following raw materials by weight: 48 parts by weight of synthetic fatty acid resin, 20 parts by weight of vegetable oleic acid resin, 8 parts by weight of acrylic resin, 0.8 parts by weight of silicon dioxide, 40 parts by weight of pigment, 0.3 parts by weight of dispersant Parts by weight, 0.9 parts by weight of leveling agent, and 3 parts by weight of defoamer, wherein the leveling agent is composed of 0.2 parts by weight of EFKA3600, 0.5 parts by weight of EFKA-3777, and 0.2 parts by weight of TEGO 450.

[0034] Component B of the embodiment of the present invention consists of the following raw materials in parts by weight: 40 parts by weight of butyl acetate, 20 parts by weight of TDI trimer, 35 parts by weight of TDI-TMP adduct, and 30 parts by weight of HDI trimer.

[0035] Component C of the embodiment of the present invention consists of the following raw materials in parts by weight: 60 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com