A resist composition with good hole masking function that can directly describe exposure imaging

A technology of resist and composition, applied in the direction of photosensitive materials, optics, and opto-mechanical equipment used in opto-mechanical equipment, can solve the problem of deterioration of film mechanical strength, reduction of resist thickness, and deterioration of masking performance, etc. problems, to achieve the effect of improving flexibility, excellent photosensitivity, and improving the masking performance of the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

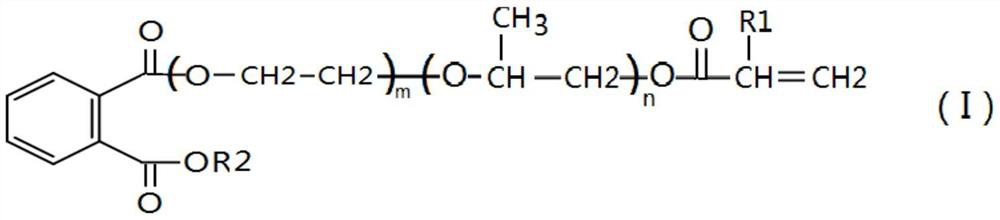

[0064] Synthesize the compound represented by general formula (I):

[0065] 1mol of phthalic anhydride, 0.20mol of butanol, 4.44g of p-toluenesulfonic acid were added to the reactor, 100mL of xylene, a thermometer, a water separator and a reflux condenser were installed, and the mixture was stirred and heated to reflux for 2.5h. Then 1 mol of ethylene glycol was added, and reflux was continued for 4 h. Next, at the reflux temperature, a mixed solution of 1.05 mol of acrylic acid and 0.02 mol of thiophenazine was added dropwise to the reactor for about 2 hours. After the dropwise addition, the temperature was kept for 5 hours. Then it was cooled to 40°C, extracted with about 150 mL of 5% sodium hydroxide, and the aqueous phase was removed. The organic phase was then extracted and washed with 150 mL of water for 2 to 3 times. The organic phase was dried with sodium carbonate, filtered, and 0.107 g of p-hydroxybenzene was added. Methyl ether was distilled off under reduced press...

Embodiment 1-5、 comparative example 1-2

[0073] Examples 1-5 and Comparative Examples 1-2 respectively provide a resist composition, the specific formula of which is shown in Table 1.

[0074] Table 1: Formulation table of resist compositions of different examples and comparative examples

[0075]

[0076] Remark:

[0077] 1. Alkali-soluble copolymer resin A-1~A-3

[0078] A-1: methacrylic acid / methyl methacrylate / hydroxyethyl methacrylate / styrene=17 / 72 / 6 / 5, weight average molecular weight is 82,000, solid content is 40%, acid value is 110.1 mgKOH / g dry resin. (Dry resin represents the resin after deducting the solvent, the same applies hereinafter).

[0079] A-2: methacrylic acid / methyl methacrylate / hydroxyethyl methacrylate / styrene=23 / 59 / 6 / 12, weight average molecular weight is 97,000, solid content is 40%, acid value is 150mgKOH / g dry resin.

[0080] A-3: methacrylic acid / methyl methacrylate / butyl acrylate / hydroxyethyl methacrylate / styrene=30 / 34 / 10 / 6 / 20, weight average molecular weight is 127,000, solid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com