A kind of matte coated paper with ultra-fine surface feel and preparation method thereof

A coated paper and matte technology, applied in the field of papermaking, can solve the problems of long-term storage, easy sticking and falling off of the powder, and achieve the effect of improving the flatness and increasing the concentration of white water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

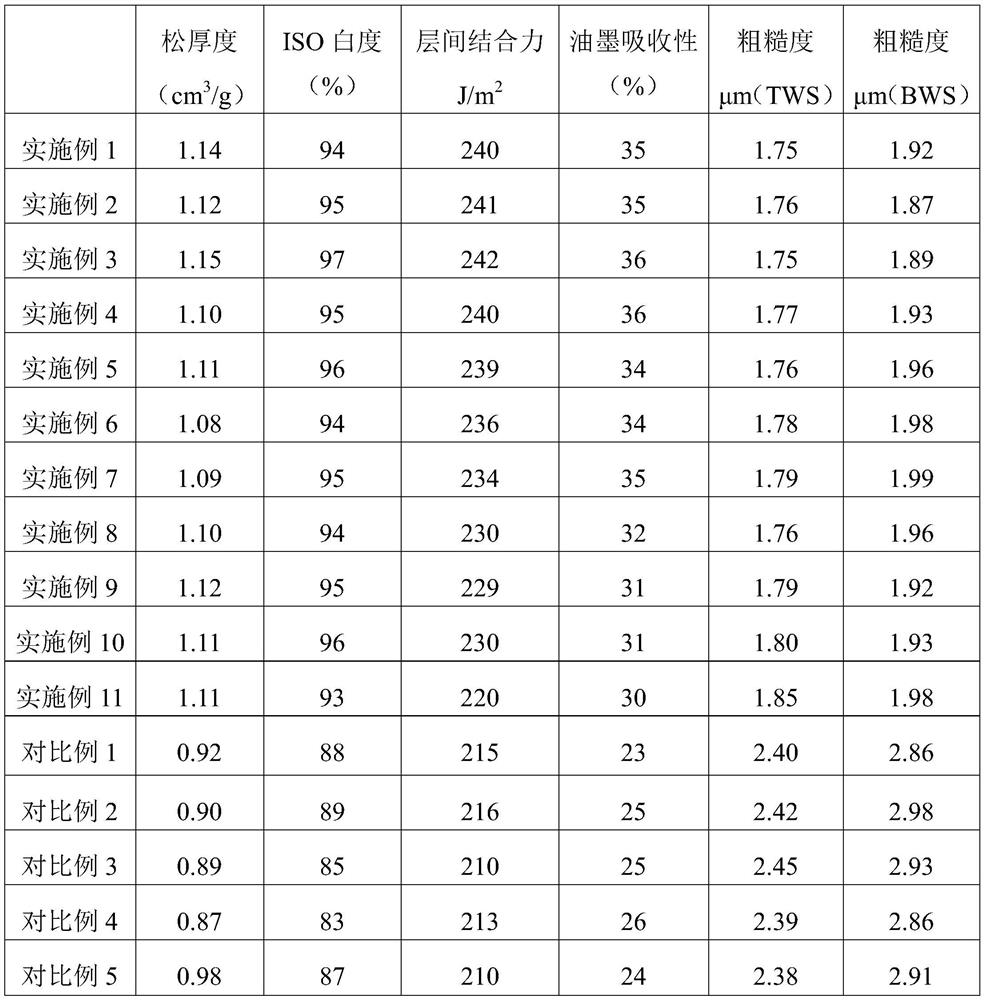

Examples

Embodiment 1

[0028] A kind of matte coated paper with delicate surface feeling: the described matte coated paper comprises the following components: a base paper layer, a precoat, and a topcoat, and the precoat and the topcoat use the same coating,

[0029] The base paper layer slurry includes the following raw materials in parts by weight: 50 parts of short fiber pulp, 5 parts of long fiber pulp, 5 parts of mechanical pulp, 2 parts of flow aid, 1 part of filter aid, 3 parts of cationic starch; The agent is sodium carboxymethyl cellulose, polyamide, eucalyptus leaf oil, apple eucalyptus oil with a weight ratio of 1:0.6:1.3:0.9, and the filter aid is a weight ratio of 1:1:0.6 Sawdust, sunflower meal powder, organic bentonite;

[0030] The coating comprises the following raw materials in parts by weight: 70 parts of ground calcium carbonate, 60 parts of light calcium carbonate, 50 parts of latex, 20 parts of starch, 4 parts of dispersant, 3 parts of defoamer, 3 parts of lubricant, 5 parts of...

Embodiment 2

[0032] A kind of matte coated paper with delicate surface feeling: the described matte coated paper comprises the following components: a base paper layer, a precoat, and a topcoat, and the precoat and the topcoat use the same coating,

[0033] The base paper layer slurry comprises the following raw materials in parts by weight: 90 parts of short fiber pulp, 30 parts of long fiber pulp, 30 parts of mechanical pulp, 5 parts of flow aid, 4 parts of filter aid, 8 parts of cationic starch; The agent is sodium carboxymethyl cellulose, polyamide, eucalyptus leaf oil, apple eucalyptus oil with a weight ratio of 3:1.5:3:2.2, and the filter aid is a weight ratio of 1:2:1.2 Sawdust, sunflower meal powder, organic bentonite;

[0034] The coating includes the following raw materials in parts by weight: 90 parts of ground calcium carbonate, 80 parts of light calcium carbonate, 70 parts of latex, 26 parts of starch, 6 parts of dispersant, 5 parts of defoamer, 9 parts of lubricant, 8 parts o...

Embodiment 3

[0036] A kind of matte coated paper with delicate surface feeling: the described matte coated paper comprises the following components: a base paper layer, a precoat, and a topcoat, and the precoat and the topcoat use the same coating,

[0037] The base paper layer slurry comprises the following raw materials in parts by weight: 70 parts of short fiber pulp, 16 parts of long fiber pulp, 21 parts of mechanical pulp, 3 parts of flow aid, 2 parts of filter aid, 5 parts of cationic starch; The agent is sodium carboxymethyl cellulose, polyamide, eucalyptus leaf oil, apple eucalyptus oil with a weight ratio of 2:1.3:10:1.2, and the filter aid is a weight ratio of 1:1.5:0.9 Sawdust, sunflower meal powder, organic bentonite;

[0038] The coating includes the following raw materials in parts by weight: 80 parts of ground calcium carbonate, 70 parts of light calcium carbonate, 60 parts of latex, 23 parts of starch, 5 parts of dispersant, 4 parts of defoamer, 6 parts of lubricant, 7 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com