A diatom-based phase-change energy storage material and its preparation method and application

A phase-change energy storage material, diatom-based technology, applied in the field of energy storage materials, can solve the problems of a single diatom, the inability to form a shell shape in large quantities, and the slow natural formation of diatomite, so as to achieve fast growth and relative The effects of large latent heat and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

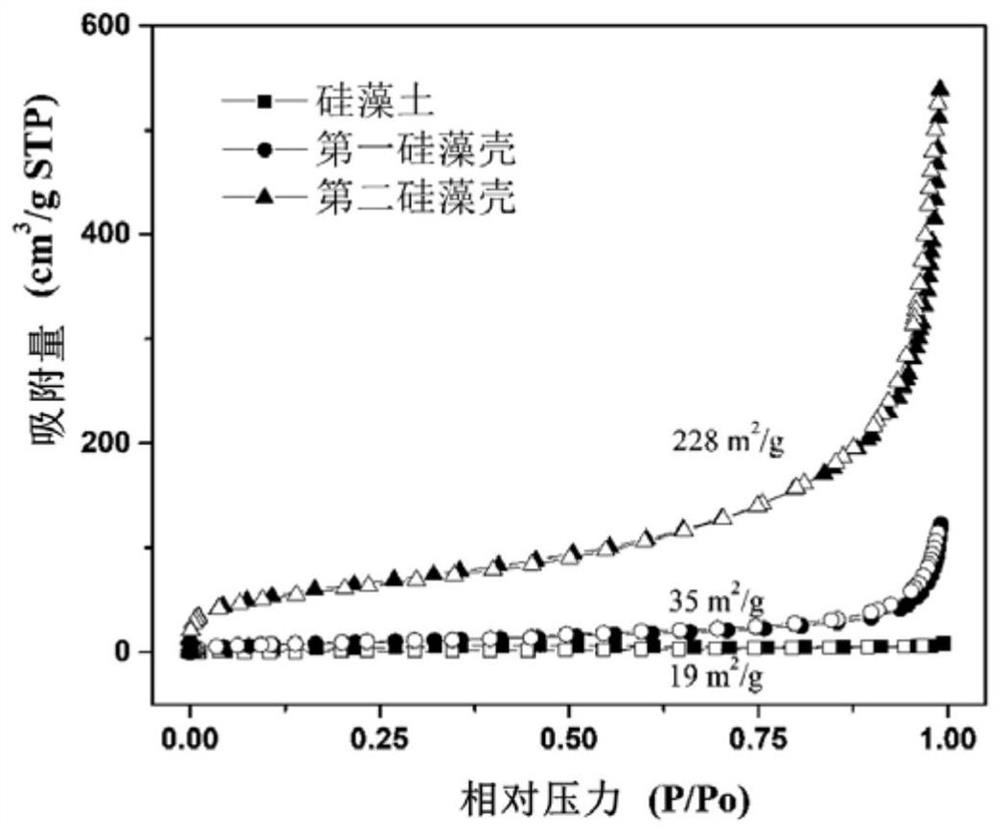

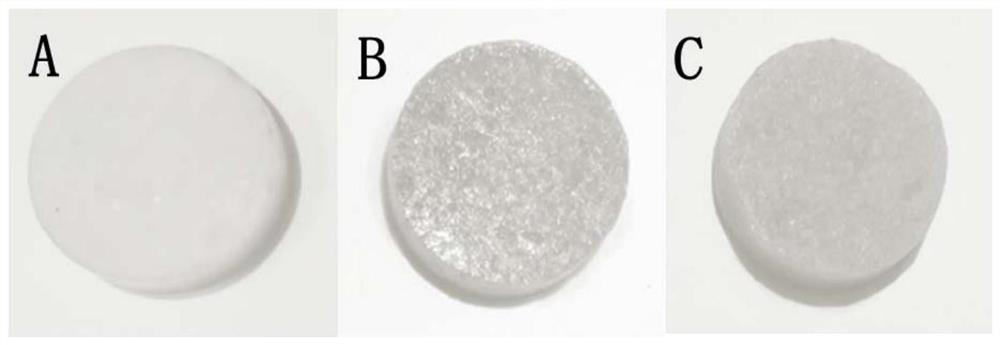

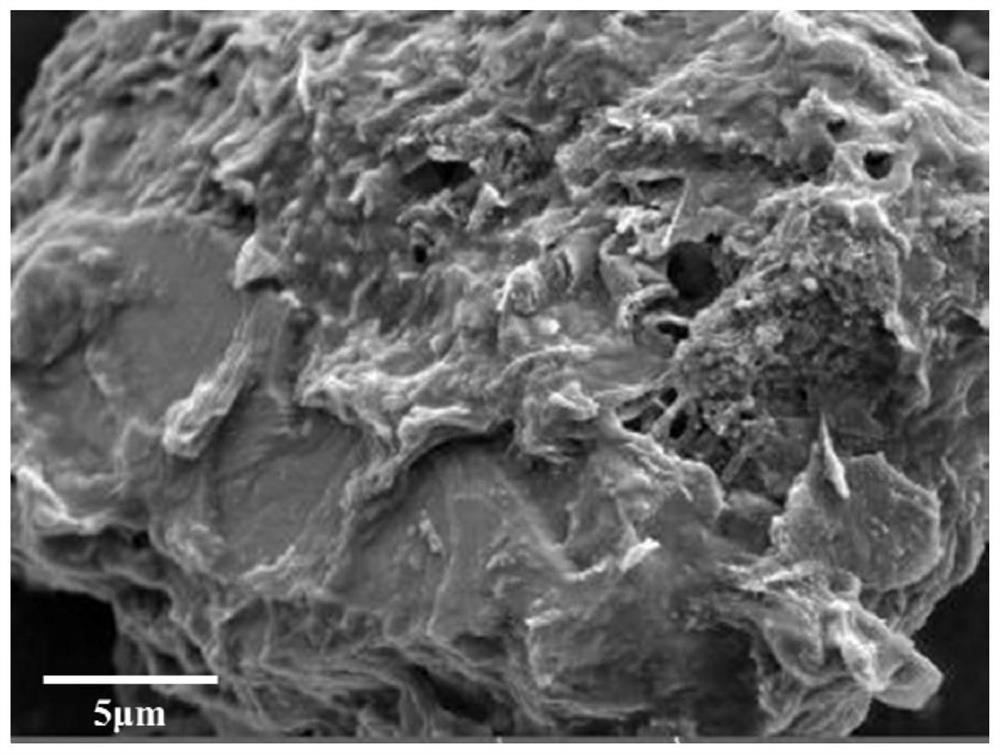

[0073] This embodiment provides a diatom-based phase change energy storage material, the phase change energy storage material is composed of diatom frustules and polyethylene glycol 4000 with a mass ratio of 0.68:1, and its preparation method includes the following steps:

[0074] (1) After the artificially cultivated diatoms are centrifuged and air-dried, they are pickled with hydrochloric acid with an acid mass concentration of 20wt% for 20 hours and dried to obtain the first diatom frustules;

[0075] Sintering the first diatom frustule at 600°C for 2 hours to obtain the second diatom frustule;

[0076] (2) Pre-mix the second diatom frustules with polyethylene glycol 4000 at a mass ratio of 33:67 to obtain a mixture, which is heated at 80°C for 1 hour under stirring conditions, and then heated at 80°C under 15kPa vacuum conditions. Under the condition of melting and impregnating for 12 hours, the molten mixture was obtained;

[0077] (3) Place the molten mixture described ...

Embodiment 2

[0079] This embodiment provides a method for preparing a diatom-based phase-change energy storage material. The phase-change energy storage material is composed of diatom frustules and polyethylene glycol 4000 with a mass ratio of 0.88:1. In addition to directly using The first diatom frustule in step (1) is pre-mixed with polyethylene glycol 4000 to prepare a diatom-based phase change energy storage material, and the ratio of the first diatom frustule to polyethylene glycol 4000 is adjusted to 47: Except 53, all the other are identical with embodiment 1.

Embodiment 3

[0081] This embodiment provides a diatom-based phase change energy storage material, the phase change energy storage material is composed of diatom frustule and lauric acid with a mass ratio of 0.35:1, and its preparation method includes the following steps:

[0082] (1) After the artificially cultured diatoms are centrifuged and air-dried, they are acid-washed with sulfuric acid whose mass concentration is 10 wt% for 48 hours and dried to obtain the first diatom frustules;

[0083] Sintering the first diatom frustule at 800°C for 1 hour to obtain the second diatom frustule;

[0084] (2) Premix the second diatom frustules with lauric acid at a mass ratio of 24:71 to obtain a mixture, which is heated at 60°C for 1 hour under stirring conditions, and then melted at 60°C under 5kPa vacuum conditions Dipping for 24 hours to obtain the molten mixture;

[0085] (3) Place the molten mixture described in step (2) on the filter paper, cool naturally to room temperature, and judge whet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com