Intermittent milling vibration subsection control method

A segmented control and milling technology, applied in the direction of digital control, program control, electrical program control, etc., can solve the problems of difficult use of the controller, conservative control parameters, excessive controller gain requirements, etc., and achieve high stability discrimination accuracy. , the effect of small controller gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

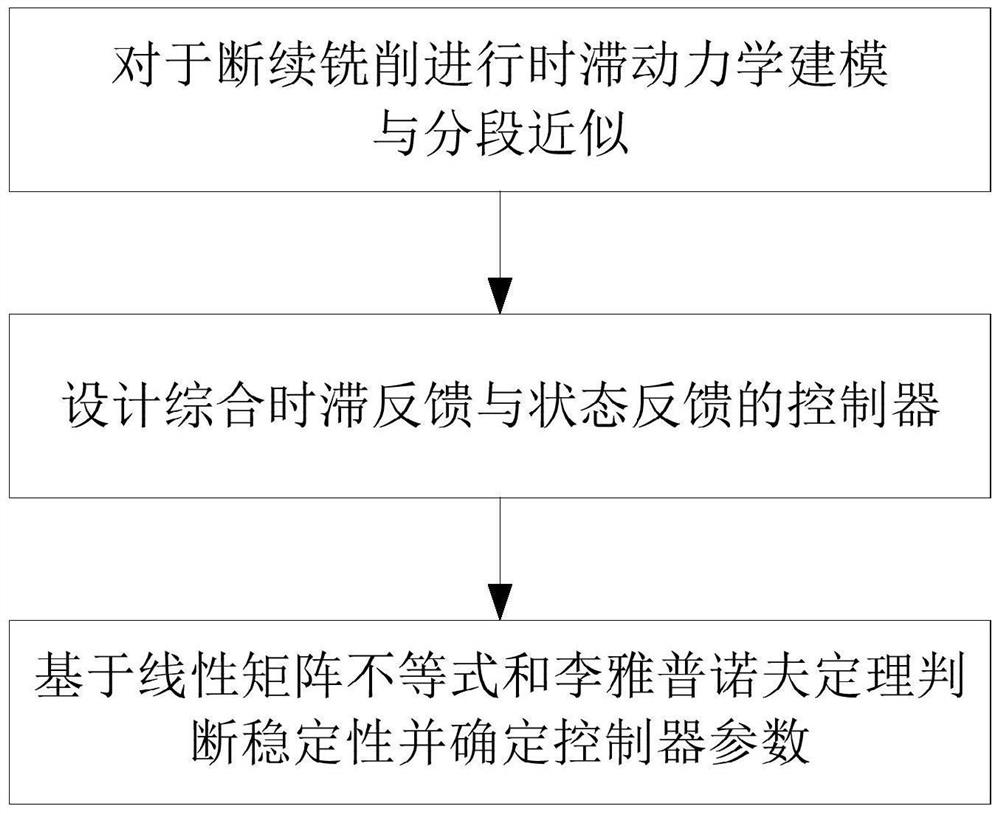

[0011] A segmented control method for intermittent milling vibration proposed in an embodiment of the present invention, including:

[0012] Step 1: Carry out time-delay dynamics modeling and segmental approximation for interrupted milling;

[0013] The interrupted milling process is divided into a free vibration period and a forced vibration period according to the contact state between the tool and the workpiece. The free vibration period is naturally stable, while the forced vibration period may be unstable; the two states are modeled separately, and the The linear approximation of the cutting force orientation coefficient in the forced vibration stage is convenient for controller design and analysis;

[0014]

[0015]

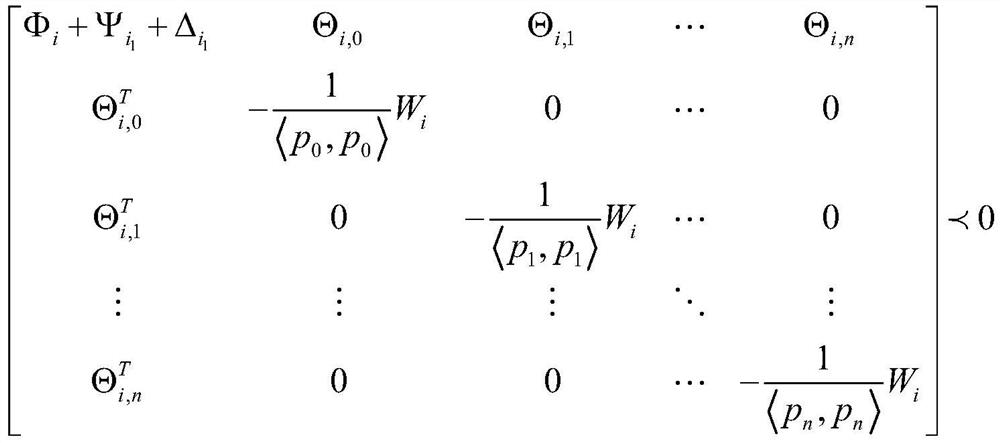

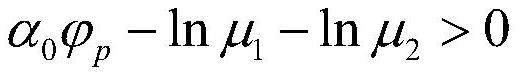

[0016] in, represents the free vibration phase, Indicates the forced vibration stage, Ω indicates the rotational speed, b indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com