Perovskite solar cell module and preparation method thereof

A technology of solar cells and perovskites, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of reduced component performance, high cost and energy consumption, and high equipment requirements, so as to reduce costs and energy Loss, reduce internal loss, reduce the effect of contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention.

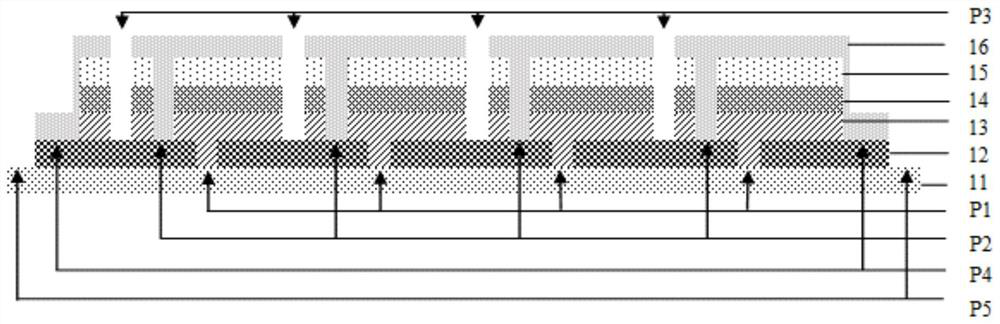

[0047] figure 1A schematic diagram of one embodiment of a titanite solar cell module of the present invention is depicted.

[0048] The perovskite solar cell assembly comprises a substrate (11), a transparent conductive layer (12), an electron transport layer (13), a perovskite absorption layer (14), a hole transport layer (15) and a back surface from bottom to top. Electrodes (16).

[0049] The perovskite solar cell module also includes:

[0050] The first channel (P1), which passes through the transparent conductive layer (12) vertically, divides the transparent conductive layer (12) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com