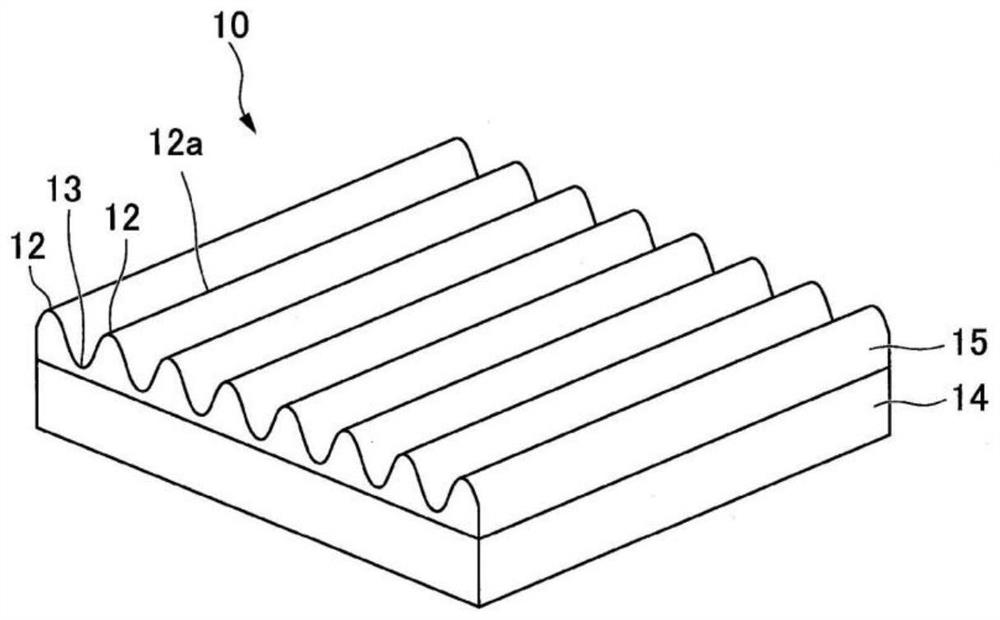

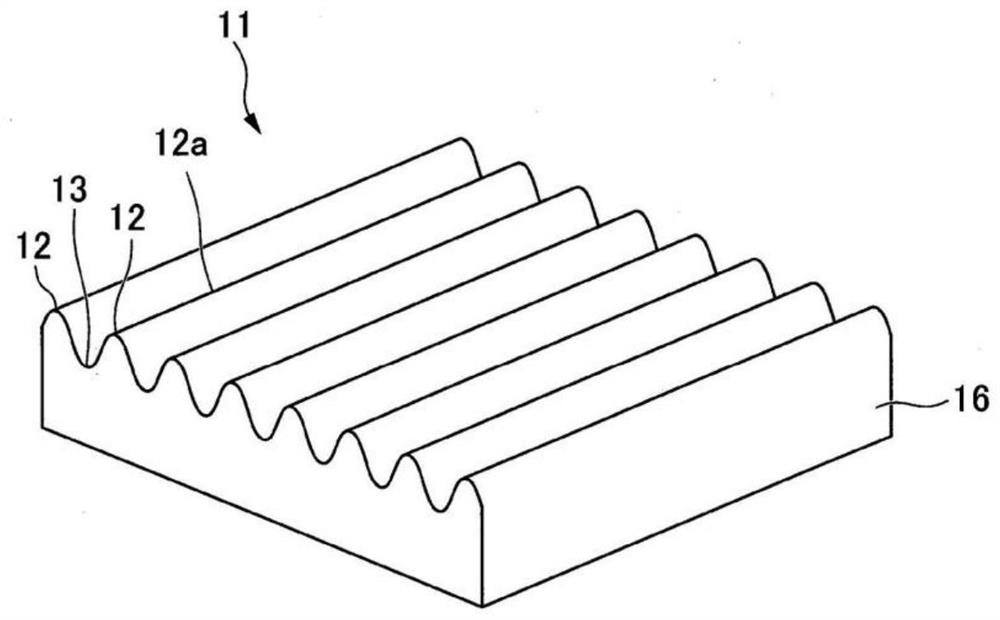

Surface relief sheet, screen, image display system and transfer roller

A technology of surface concavo-convex and transfer roller, which can be used in instruments, projection devices, optics, etc., and can solve problems such as image brightness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0261] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited to these.

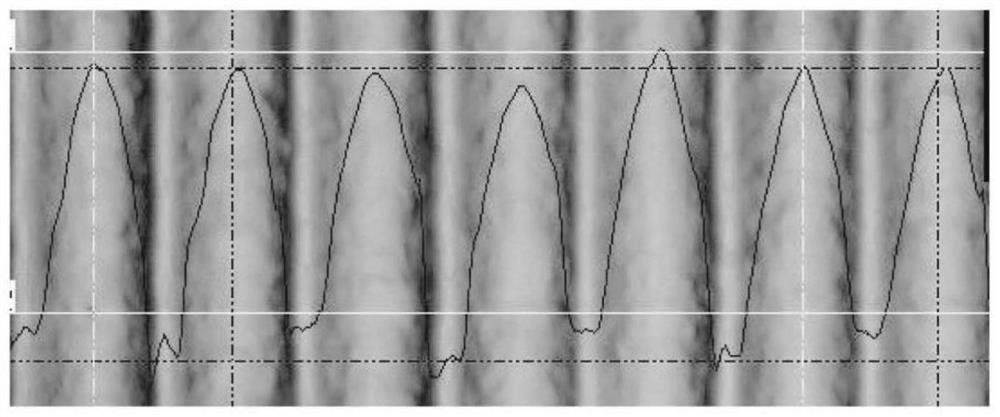

[0262] (Average depth of concave lines of transfer roller)

[0263] The average depth of the concave lines of the transfer roller was obtained as follows.

[0264] The surface unevenness of the transfer roller was measured using a laser microscope (VK-8500, manufactured by KEYENCE) with an objective lens of 50 times and a measurement pitch of 0.1 μm. Then, as Figure 8As shown, the cross-sectional shape corresponding to the cross-section when the vicinity of the surface of the transfer roller is cut along the direction orthogonal to the extending direction of the grooved lines 102 and toward the center of the transfer roller is measured. The depth D1 from the top 103a of one of the convex lines 103 adjacent to the concave line 102 to the bottom 102a of the concave line 102 is measured. Similarly, the depth D2 from the top 103a of ...

manufacture example 1

[0318] (Refer to coating liquid for light diffusing sheet)

[0319] A coating liquid for a reference light-diffusing sheet of the following composition was prepared.

[0320] Acrylic resin (100% non-volatile content, glass transition temperature 105°C, weight average molecular weight 600,000): 8 parts by mass,

[0321] Cross-linked polystyrene (polystyrene) particles (manufactured by Sekisui Chemical Industry Co., Ltd., SBX-6, average particle diameter 6.4 μm, no glass transition temperature): 13.2 parts by mass,

[0322] Cross-linked polystyrene particles (manufactured by Sekisui Chemicals Co., Ltd., SBX-12, average particle diameter 11.7 μm, no glass transition temperature): 9.6 parts by mass,

[0323] Cross-linked polystyrene particles (manufactured by Sekisui Chemical Industry Co., Ltd., SBX-17, average particle diameter 16.1 μm, no glass transition temperature): 1.2 parts by mass,

[0324] Toluene: 68 parts by mass.

[0325] (Refer to Light Diffuser Sheet)

[0326] On...

Embodiment 1

[0330] (transfer roller)

[0331] On the surface of the roller body whose surface material is copper, a ytterbium fiber laser (manufactured by IPG Photonics) attached to the laser engraving device was used. The beam diameter of the laser was 2.8 μm, the laser output was 200 W, the laser pulse A plurality of concave lines extending in the circumferential direction of the roller body were engraved under the condition of a roller peripheral speed of 45 cm / s.

[0332] Water cleaning (pure water, 25 kHz ultrasonic cleaning) was performed on the roller body engraved with a plurality of concave lines for 5 minutes. Next, after acid cleaning was performed at 50° C. for 12 minutes with an acid solution (aqueous sulfuric acid solution with a concentration of 10% (v / v)), an electroforming solution (nickel sulfamate (nickel sulfamate) 600 g / liter, nickel chloride 5 g) was used. / L, boric acid 40g / L, sodium naphthalene sulfonate 0.5g / L, sodium lauryl sulfate 1g / L), at liquid temperature 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com