Vegetable oil processing process

A processing technology and vegetable oil technology, applied in the field of vegetable oil, can solve the problems of inaccurate control of oil fragrance, product fragrance cannot be well reflected, and difficult to control temperature point, etc., so as to expand the market scope, reliable fragrance type and Stabilizes and resolves palatability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

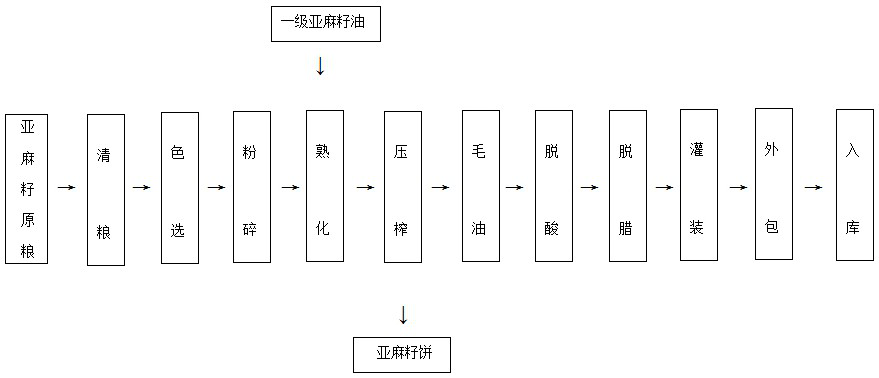

[0055] A kind of vegetable oil processing technology, described processing technology comprises the following steps, with reference to figure 1 Process flow chart:

[0056] 1. Purification of raw materials: select fresh and mature flaxseed oil seeds with uniform quality, remove impurities larger and smaller than the diameter of flaxseed in the raw grain, and remove stones and iron; color sorting: further remove impurities to make the purity of flaxseed reach 99.9% to ensure the pure aroma and flavor of the product linseed oil.

[0057] 2. Raw material crushing: grind the linseed coarse powder to about 15 meshes, increase the heating area when linseed is ripening, shorten the ripening time, and increase the oil yield at the same time.

[0058] 3. Maturation of raw materials: use first-grade linseed oil as the heating medium and crushed linseeds in a mass ratio of 1:1 and mix them together in a heat-conducting oil jacketed pot, heat while stirring, so that the linseeds are eve...

Embodiment 2

[0065] A vegetable oil processing technology, the difference from Example 1 is that the mass ratio of the base oil to the pulverized raw material is 1:1.5.

Embodiment 3

[0067] A vegetable oil processing technology, the difference from Example 1 is that the mass ratio of the base oil to the pulverized raw material is 1:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com