Aero engine air compressor inner cartridge receiver with air-bleed holes and machining method thereof

An aero-engine and compressor technology, which is applied in machine/engine, liquid fuel engine, metal processing, etc., can solve the problems of over-temperature at the hot end of the engine, reduced efficiency, and reduced pressure ratio at the surge point, so as to ensure stable operation, The effect of easy guidance and accelerated discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

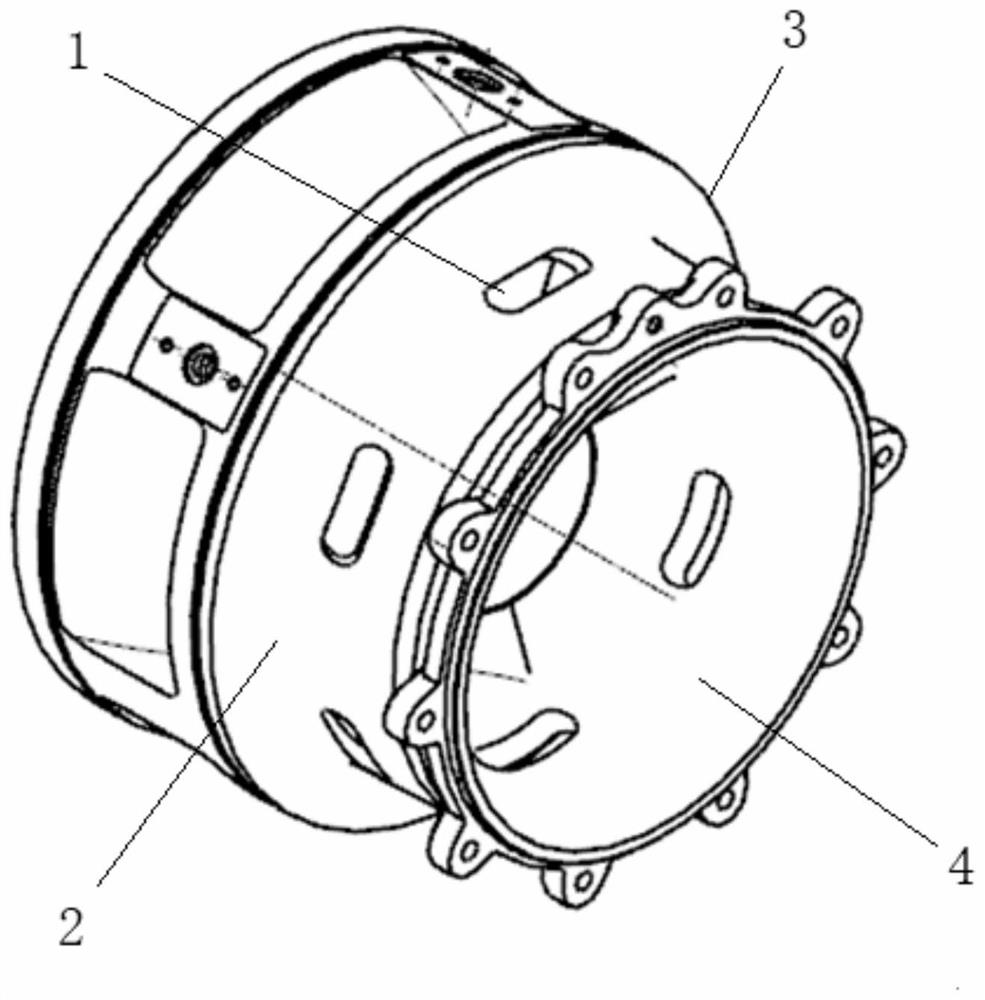

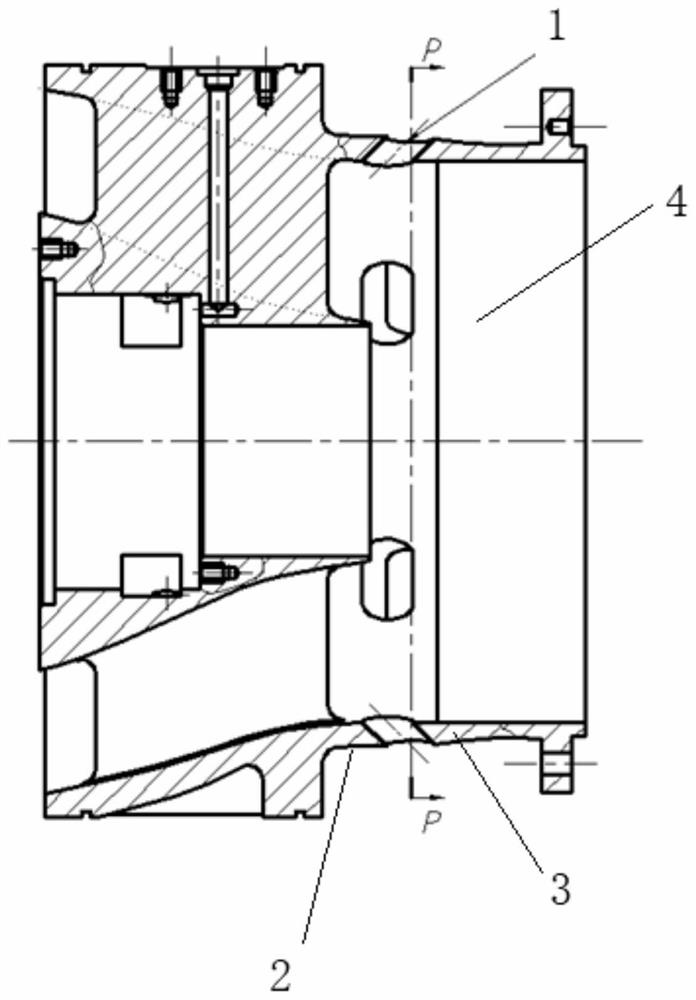

[0017] Such as Figure 1 to Figure 4 As shown, the inner casing of the aeroengine compressor with vent holes in this embodiment includes an inner casing body 3, and 6 waist-shaped vent holes 1 and 6 are evenly distributed along the circumferential direction on the middle side wall 2 of the inner casing body 3 Waist-shaped venting holes 1 are placed on the same circumference; the normal direction of each waist-shaped venting hole 1 is set at an angle of 45° to the axial direction of the inner casing of the compressor, that is, the normal direction of waist-shaped venting holes 1 is in the direction of airflow The included angle is set at 45º; the two ends of each waist-shaped vent hole 1 are set in a semicircle; when in use, the waist-shaped vent hole 1 guides the airflow flowing along the inner wall of the inner casing, so that the airflow can flow through the waist-shaped vent hole 1 The flow is diverted to the outside of the airflow passage 4 of the compressor inner casing t...

Embodiment 2

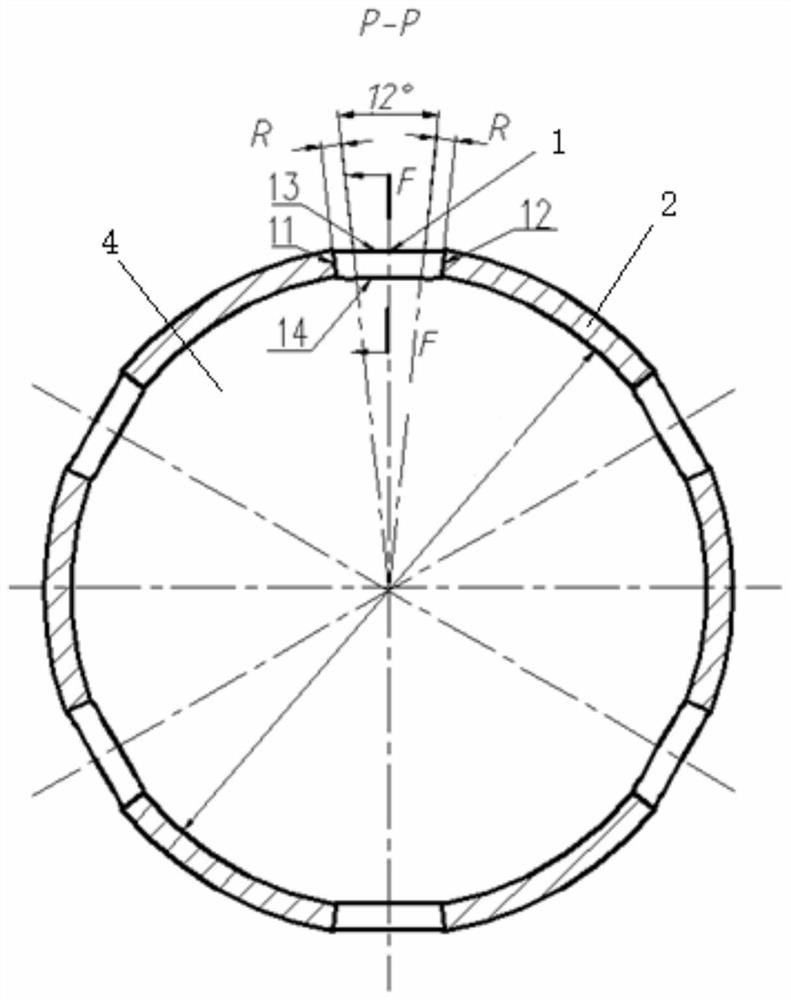

[0019] The processing method of the aero-engine compressor inner casing with bleed holes described in embodiment 1 comprises the following steps: draw a complete circle on the inner wall of the compressor inner casing, and cut six 12° circles on the circumference arc, and make 6 arcs evenly distributed on the circumference; at both ends of each arc, take the two endpoints of each arc as the center of the circle and make a semicircle with radius R along the inner wall of the compressor inner casing, respectively The first arc 11 and the second arc 12 connect the corresponding end points of the two semicircles by making a curve along the inner wall of the compressor casing, that is, connect the upper end point of the first arc 11 with the second arc through the first curve 13. The upper endpoint of the line 12 is connected, and the lower endpoint of the first arc 11 is connected with the lower endpoint of the second arc 12 by the second curve 14, by the first arc 11, the first cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com