Compound, liquid crystal composition, and liquid crystal display device

A technology for liquid crystal compositions and compounds, applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., to achieve the effects of fast conversion, good ultraviolet resistance and good diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0124] The preparation method of the liquid crystal composition is as follows: put each liquid crystal monomer into a stainless steel beaker after weighing according to a certain proportion, place the stainless steel beaker containing each liquid crystal monomer on a magnetic stirring apparatus to heat and melt, and wait for the liquid crystal monomer in the stainless steel beaker to melt. After most of the liquid crystal monomers are melted, a magnetic rotor is added to the stainless steel beaker, the mixture is stirred evenly, and the liquid crystal composition is obtained after cooling to room temperature.

[0125] The preparation method of the liquid crystal display device is as follows: First, uniformly coat the alignment material on the surface of the first substrate and the second substrate, the alignment material can be polyimide, heat and cure the evenly coated alignment material, and the heating temperature is 230°C , to form an alignment layer; secondly, spacers are ...

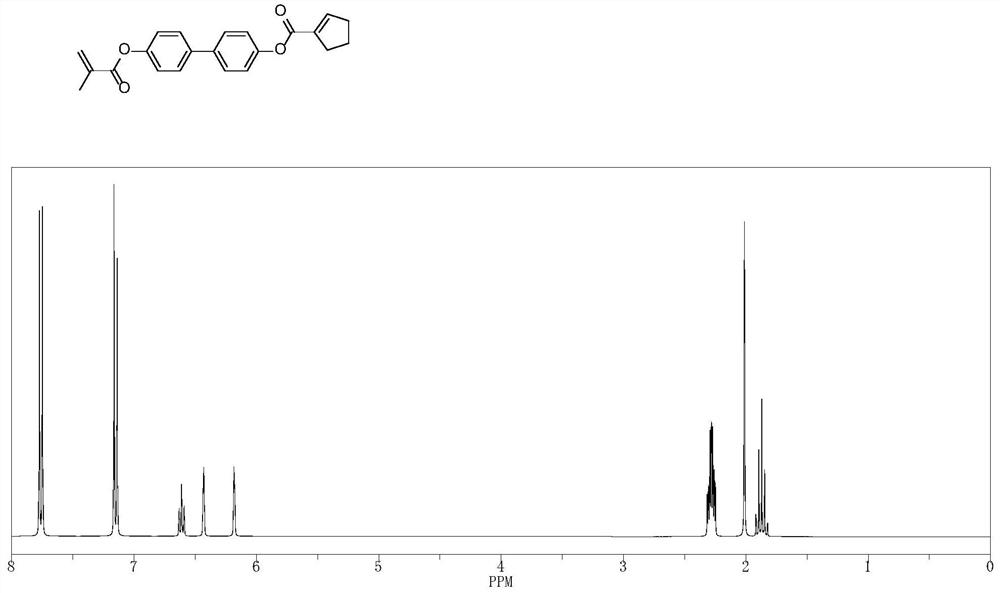

Embodiment 1

[0151] The structural formula of the compound is shown in the following formula Ⅰ-1-1:

[0152]

[0153] Its preparation route is as follows:

[0154]

[0155] The specific operation process of preparation:

[0156] The first step: the preparation of intermediate 3

[0157] Put 0.1 mol of compound 1, 0.1 mol of compound 2, 0.1 mol of dicyclohexylcarbodiimide (hereinafter referred to as "DCC"), and 0.5 L of tetrahydrofuran into a 1 L three-necked flask, and react at room temperature for 2 hours under nitrogen protection. The solid was suctioned, the organic phase was washed with 0.2 L of water, the organic phase was passed through a 50 g silica gel column, washed with 0.1 L of toluene, and spin-dried to obtain intermediate 3.

[0158] Step 2: Compound I-1-1

[0159] 0.02 mol of the aforementioned intermediate 3, 0.02 mol of cyclopentenecarboxylic acid, 0.5 L of tetrahydrofuran, and 0.02 mol of DCC were put into a 1 L three-necked flask, and reacted for 3 hours at room ...

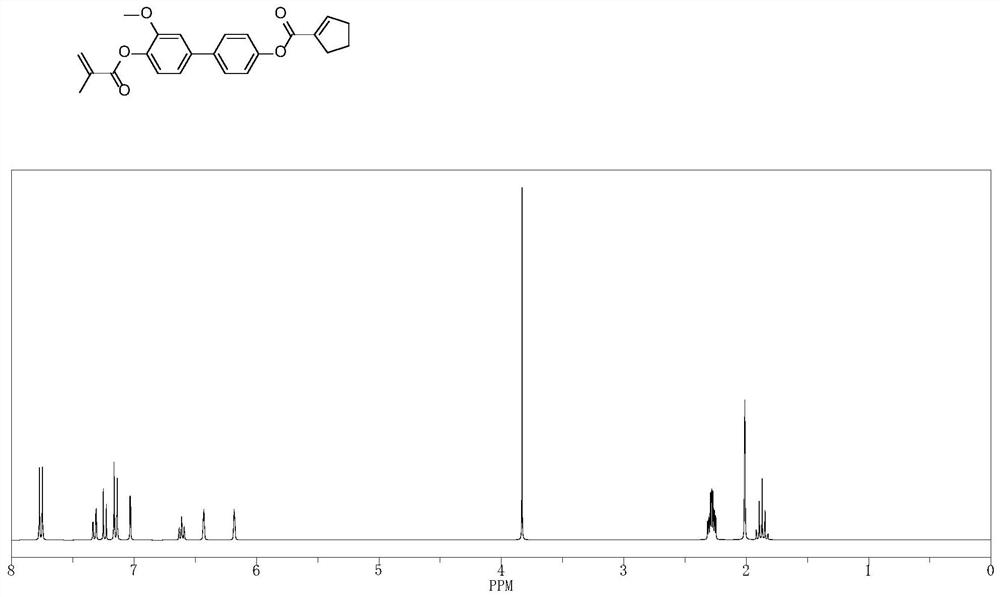

Embodiment 2

[0161] The structural formula of the compound is shown in the following formula Ⅰ-1-2:

[0162]

[0163] Its preparation route is as follows:

[0164]

[0165] The specific operation process of preparation:

[0166] The first step: the preparation of intermediate 6

[0167] Put 0.1 mol of compound 5, 0.1 mol of compound 2, 0.1 mol of dicyclohexylcarbodiimide (hereinafter referred to as "DCC"), and 0.5 L of tetrahydrofuran into a 1 L three-necked flask, and react at room temperature for 2 hours under nitrogen protection. The solid was suctioned, and the organic phase was washed with 0.2 L of water. The organic phase was passed through a 50 g silica gel column, washed with 0.1 L of toluene, and spin-dried to obtain intermediate 6.

[0168] The second step: the preparation of compound I-1-2

[0169] 0.02 mol of the aforementioned intermediate 6, 0.02 mol of cyclopentenecarboxylic acid, 0.5 L of tetrahydrofuran, and 0.02 mol of DCC were put into a 1 L three-necked flask, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com