Stainless steel grinding tooth machining liquid and preparation method thereof

A processing fluid and stainless steel technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as volatile odor, easy breeding of bacteria, flashing and even burning sites, etc., to reduce microbial breeding, reduce bacterial breeding, and prevent breeding The effect of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

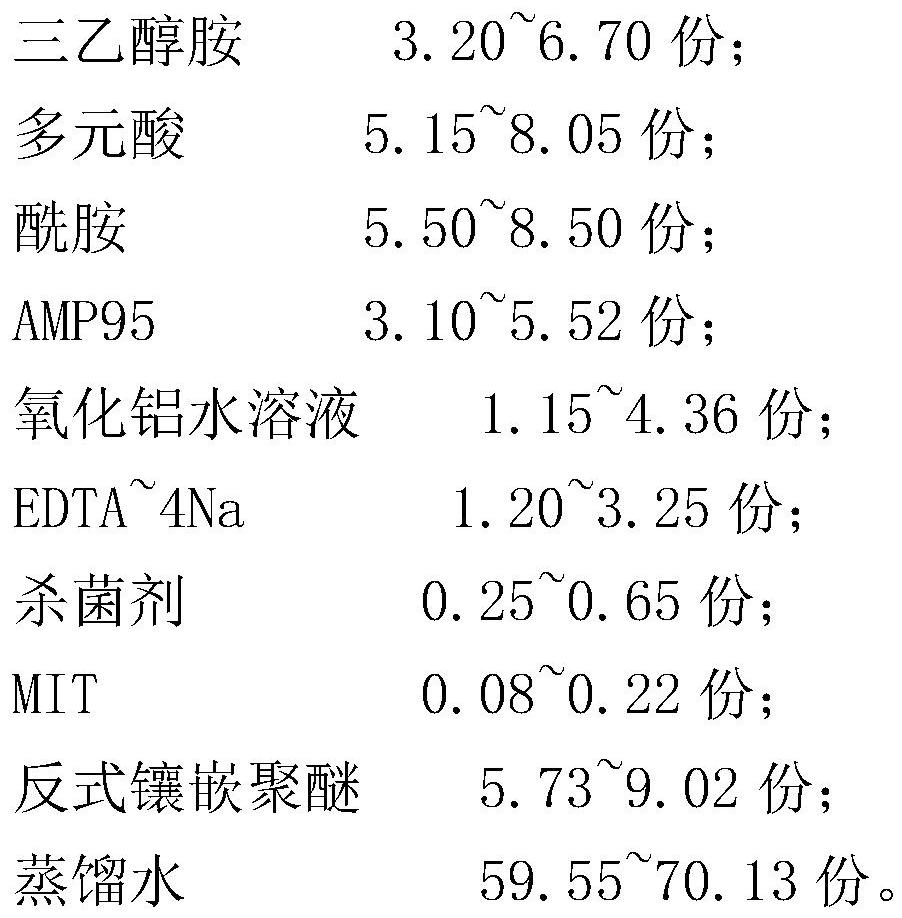

[0043] A kind of stainless steel tooth milling liquid, comprises following parts by weight:

[0044]

[0045] A preparation method of a stainless steel tooth grinding fluid, comprising the steps of:

[0046] S1. Mix 0.25 parts of fungicide and 0.08 parts of MIT evenly, and let stand for more than 20 minutes;

[0047] S2. First put triethanolamine into the reaction kettle, add distilled water, then put in powdery polybasic acid, and keep stirring for more than 20 minutes;

[0048] S3. Observe that there is no powdery object, and then add amide, AMP95, aluminum oxide aqueous solution, EDTA-4Na in sequence, and stir it until it is completely dissolved into a colorless liquid;

[0049] S4. Add the mixture of BIT and MIT after standing for 20 minutes, stir for 5 minutes and then take a sample for inspection.

[0050] Packaging after passing the inspection.

[0051] The stainless steel tooth milling fluid test result in the embodiment 1 of table 1

[0052] Test items...

Embodiment 2

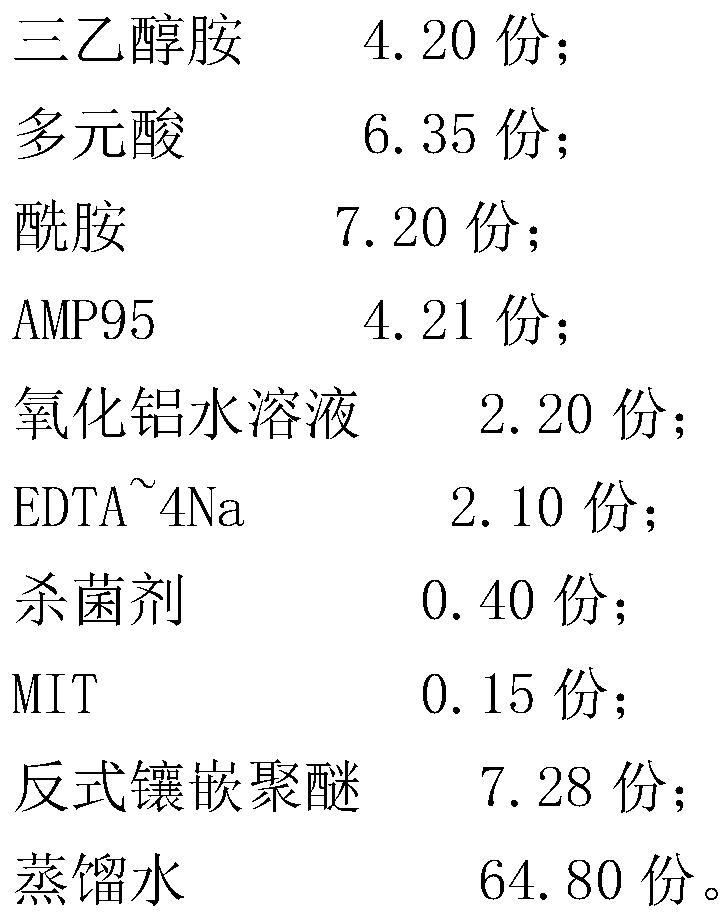

[0054] A kind of stainless steel tooth milling liquid, comprises following parts by weight:

[0055]

[0056] A preparation method of a stainless steel tooth grinding fluid, comprising the steps of:

[0057] S1. Mix 0.25-0.65 parts of fungicide and 0.08-0.22 parts of MIT evenly, and let stand for more than 20 minutes;

[0058] S2. First put triethanolamine into the reaction kettle, add distilled water, then put in powdery polybasic acid, and keep stirring for more than 20 minutes;

[0059] S3. Observe that there is no powdery object, and then add amide, AMP95, aluminum oxide aqueous solution, EDTA-4Na in sequence, and stir it until it is completely dissolved into a colorless liquid;

[0060] S4. Add the BIT and MIT mixture after standing for 20 minutes, stir for 5 minutes and then take a sample for inspection, and pack after passing the inspection.

[0061] The stainless steel tooth milling fluid test result in the embodiment 2 of table 2

[0062] Test items T...

Embodiment 3

[0064] A kind of stainless steel tooth milling liquid, comprises following parts by weight:

[0065]

[0066] A preparation method of a stainless steel tooth grinding fluid, comprising the steps of:

[0067] S1. Mix 0.65 parts of fungicide and 0.22 parts of MIT evenly, and let stand for more than 20 minutes;

[0068] S2. First put triethanolamine into the reaction kettle, add distilled water, then put in powdery polybasic acid, and keep stirring for more than 20 minutes;

[0069] S3. Observe that there is no powdery object, and then add amide, AMP95, aluminum oxide aqueous solution, EDTA-4Na in sequence, and stir it until it is completely dissolved into a colorless liquid;

[0070] S4. Add the BIT and MIT mixture after standing for 20 minutes, stir for 5 minutes and then take a sample for inspection, and pack after passing the inspection.

[0071] The stainless steel tooth milling fluid test result in the embodiment 3 of table 3

[0072] Test items Testing metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com