Heat-resistant spring steel with tensile strength larger than 2100 MPa and production method thereof

A 2100mpa, tensile strength technology, applied in the field of spring steel, can solve the problems of poor tensile strength, strong toughness, impact resistance and fatigue strength, poor performance, and difficulty in use, to improve high temperature performance and good heat resistance. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

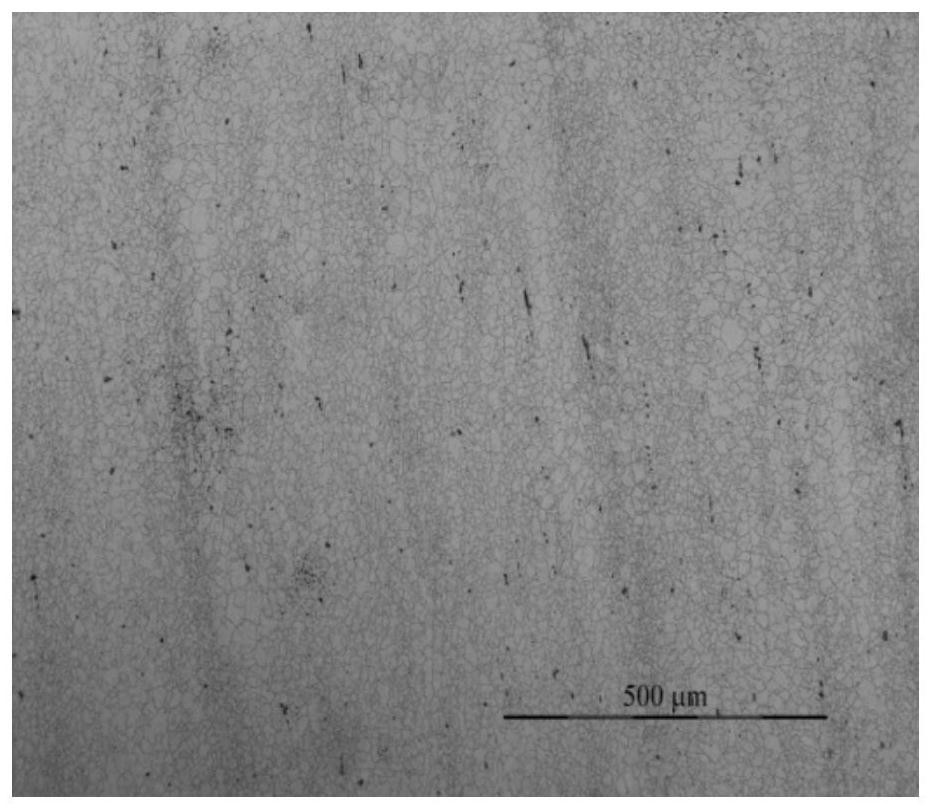

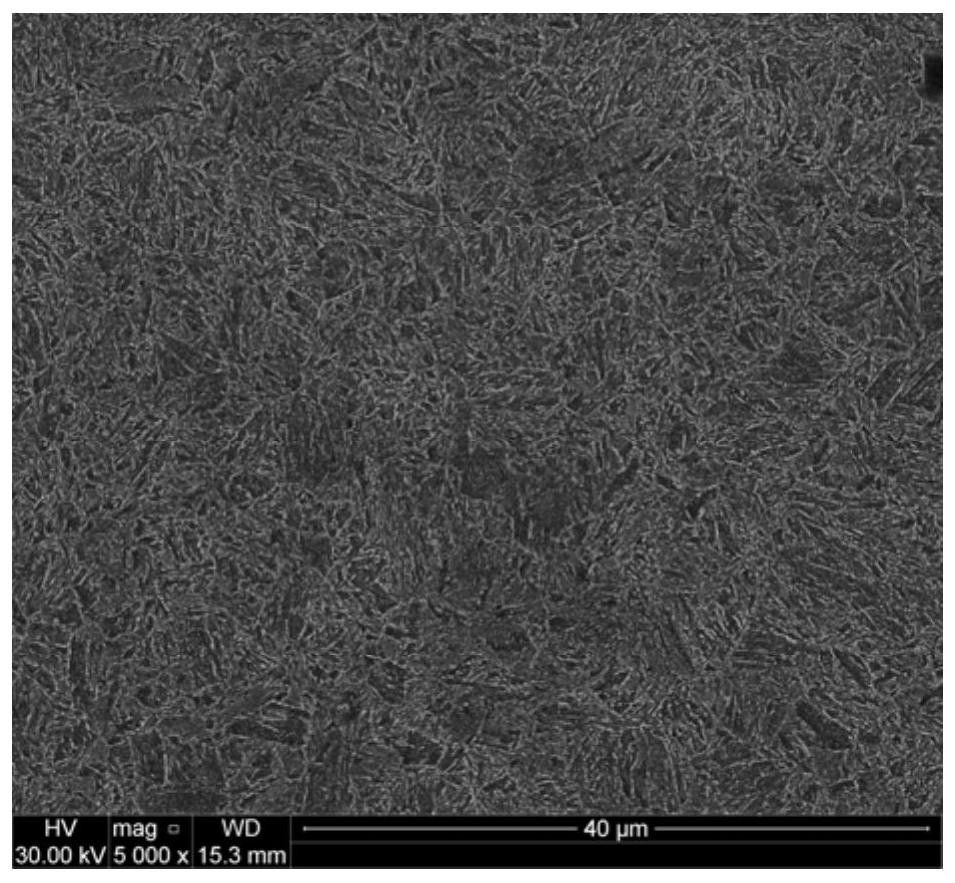

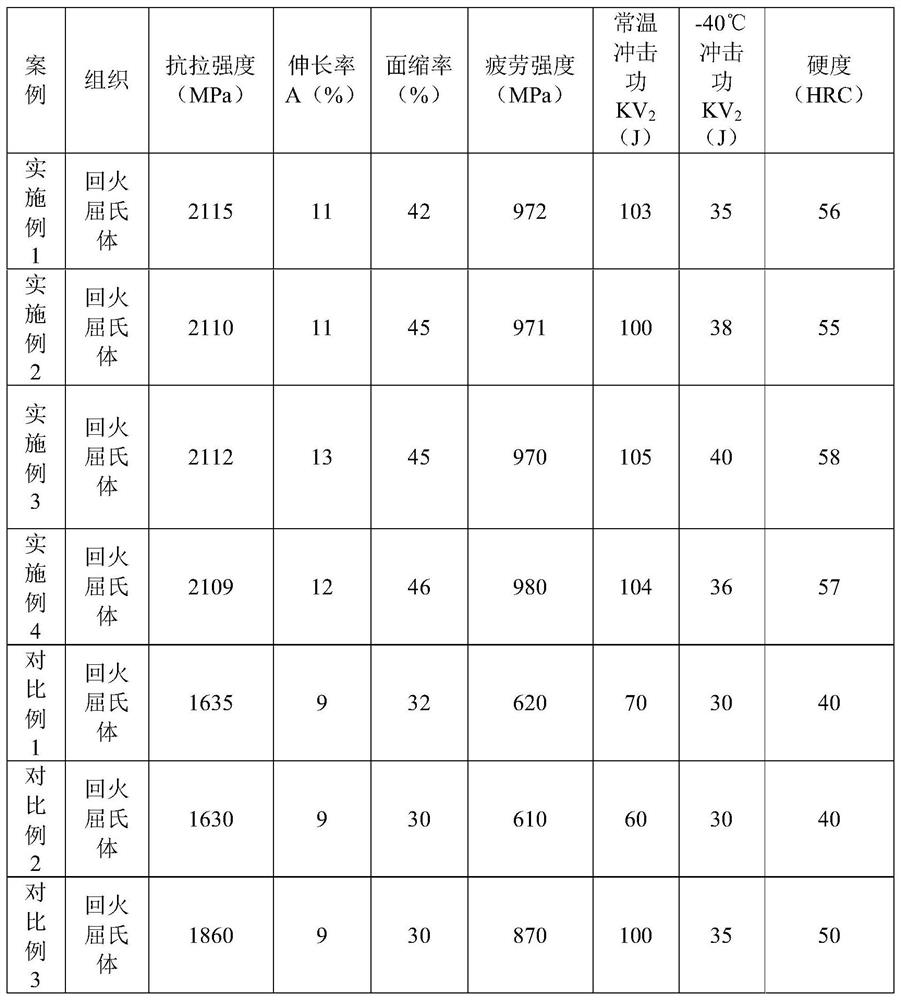

[0063] The spring steel of this embodiment has chemical composition: C: 0.55%, Si: 1.80%, Mn: 0.80%, Cr: 1.10%, V: 0.15%, Nb: 0.040%, Mo: 0.10%, W: 0.60 %, P: 0.015%, S: 0.010%, O: 0.0010%, N: 0.005%, the rest is Fe and other unavoidable impurities. The hot rolled structure of the wire rod is pearlite + ferrite, and its austenite grain size is 11 grades.

[0064] The processing steps adopt the process flow of the present invention, wherein the double quenching heat treatment conditions are:

[0065] Quench at 850℃ for 20min (oil cooling), temper at 480℃ for 120min (air cooling)→quench at 800℃ for 20min (oil cooling), temper at 400℃ for 120min (air cooling).

[0066] Then the room temperature mechanical properties and high temperature mechanical properties after double quenching heat treatment are tested, and the results are shown respectively image 3 and Figure 4 . Finally, its thermal conductivity at different temperatures was tested, and the results are shown in Figure 5 .

Embodiment 2

[0068] The chemical composition of the spring steel of this embodiment is: C: 0.65%, Si: 1.30%%, Mn: 0.70%, Cr: 1.20%, V: 0.35%, Nb: 0.02%, Mo: 0.12%, W: 0.65%, P: 0.012%, S: 0.020%, O: 0.0009%, N: 0.002%, the rest is Fe and other unavoidable impurities. The hot rolled structure of the wire rod is pearlite + ferrite, and its austenite grain size is 11.5.

[0069] The processing steps adopt the process flow of the present invention, wherein the double quenching heat treatment conditions are:

[0070] Quenching at 860℃ for 30min (oil cooling), tempering at 500℃ for 120min (air cooling) → quenching at 830℃ for 30min (oil cooling), tempering at 430℃ for 120min (air cooling).

[0071] Then the room temperature mechanical properties and high temperature mechanical properties after double quenching heat treatment are tested, and the results are shown respectively image 3 and Figure 4 .

[0072] Finally, its thermal conductivity at different temperatures was tested, and the results are sho...

Embodiment 3

[0074] The spring steel of this embodiment has chemical composition: C: 0.65%, Si: 2.00%, Mn: 0.90%, Cr: 1.10%, V: 0.16%, Nb: 0.02%, Mo: 0.10%, W: 1.20 %, P: 0.018%, S: 0.010%, O: 0.0006%, N: 0.007%, and the rest are Fe and other unavoidable impurities. The hot rolled structure of the wire rod is pearlite + ferrite, and its austenite grain size is 11.5.

[0075] The processing steps adopt the process flow of the present invention, wherein the double quenching heat treatment conditions are:

[0076] Quenching at 870℃ for 30min (oil cooling), tempering at 450℃ for 100min (air cooling)→quenching at 820℃ for 30min (oil cooling), tempering at 450℃ for 100min (air cooling).

[0077] Then the room temperature mechanical properties and high temperature mechanical properties after double quenching heat treatment are tested, and the results are shown in image 3 and Figure 4 .

[0078] Finally, its thermal conductivity at different temperatures was tested, and the results are shown in Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com