Anti-freezing treatment agent and application method thereof

An application method and technology of treatment agent, applied in the directions of physical treatment of paper, fiber raw material treatment, flexible covering, etc., can solve problems such as the decline of paper performance, achieve good water retention performance, avoid the decline of paper mechanical properties, and ensure quality stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

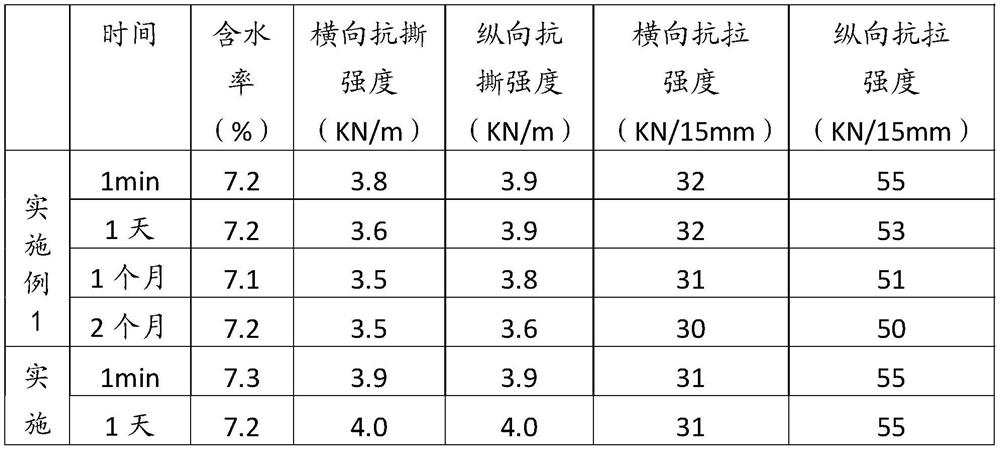

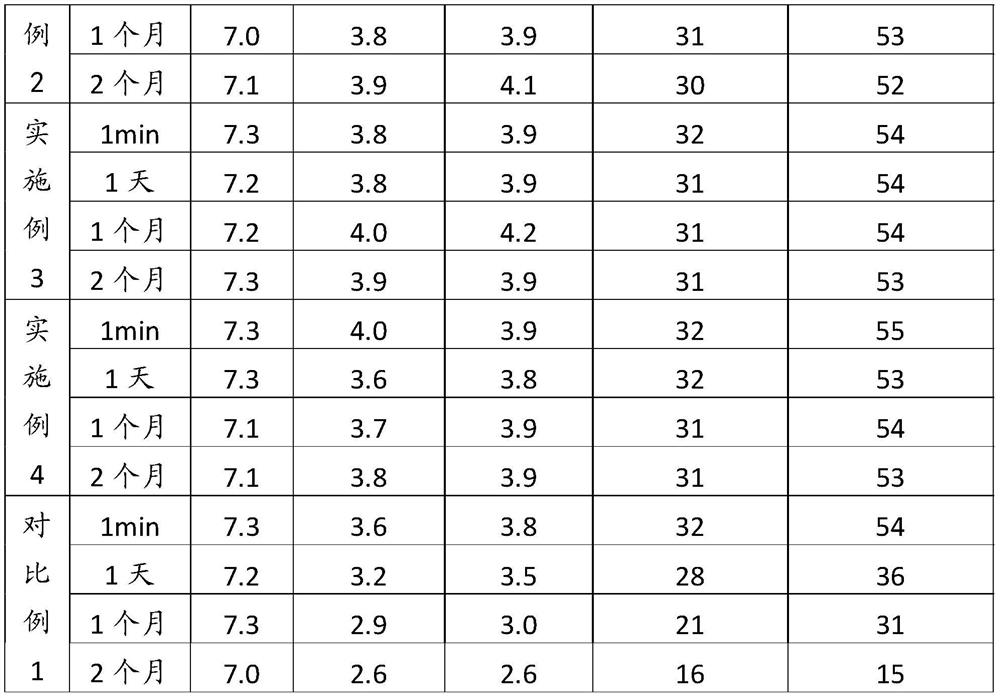

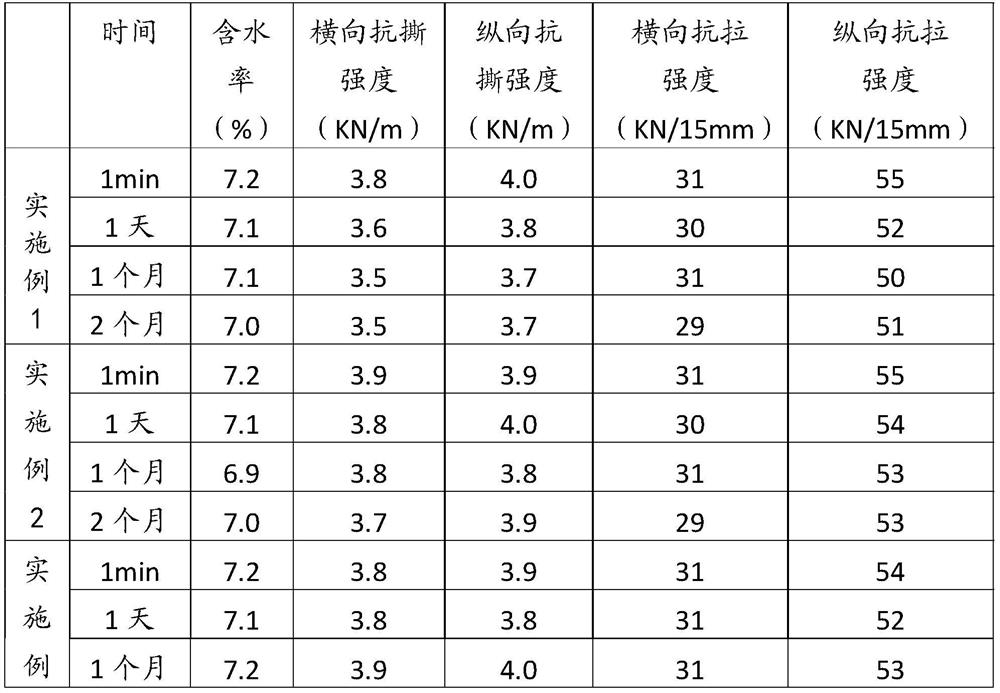

Embodiment 1

[0024] The antifreeze agent was prepared in the following proportions: glycerin 50%, antifreeze peptide 0.1%, D-sorbitol 2%, ethanol 7%, and the balance was water.

[0025] Choose long-fiber leaf-increasing pulp base paper as the base layer of the wrapping paper, and immerse the base layer of the wrapping paper in the antifreeze treatment agent at a speed of 100-150 m / min through a roll; after drying, the upper surface of the base layer is coated with gloss The oil layer is coated with a wax layer on the lower surface, and the low-temperature frozen food outer wrapping paper is prepared after cutting.

Embodiment 2

[0027] The antifreeze agent was prepared in the following proportions: glycerin 50%, antifreeze peptide 0.3%, D-sorbitol 2%, ethanol 7%, and the balance was water.

[0028] Choose long-fiber leaf-increasing pulp base paper as the base layer of the wrapping paper, and immerse the base layer of the wrapping paper in the antifreeze treatment agent at a speed of 100-150 m / min through a roll; after drying, the upper surface of the base layer is coated with gloss The oil layer is coated with a wax layer on the lower surface, and the low-temperature frozen food outer wrapping paper is prepared after cutting.

Embodiment 3

[0030] The antifreeze agent was prepared in the following proportions: glycerin 50%, antifreeze peptide 0.5%, D-sorbitol 2%, ethanol 7%, and the balance was water.

[0031] Choose long-fiber leaf-increasing pulp base paper as the base layer of the wrapping paper, and immerse the base layer of the wrapping paper in the antifreeze treatment agent at a speed of 100-150 m / min through a roll; after drying, the upper surface of the base layer is coated with gloss The oil layer is coated with a wax layer on the lower surface, and the low-temperature frozen food outer wrapping paper is prepared after cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com