Sea surface petroleum collecting robot and using method thereof

A robot and petroleum technology, applied in instruments, alarms, general water supply and conservation, etc., can solve problems such as low efficiency, inconvenient transportation, large size, etc., and achieve the effects of easy replacement and maintenance, fast and efficient cleaning, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

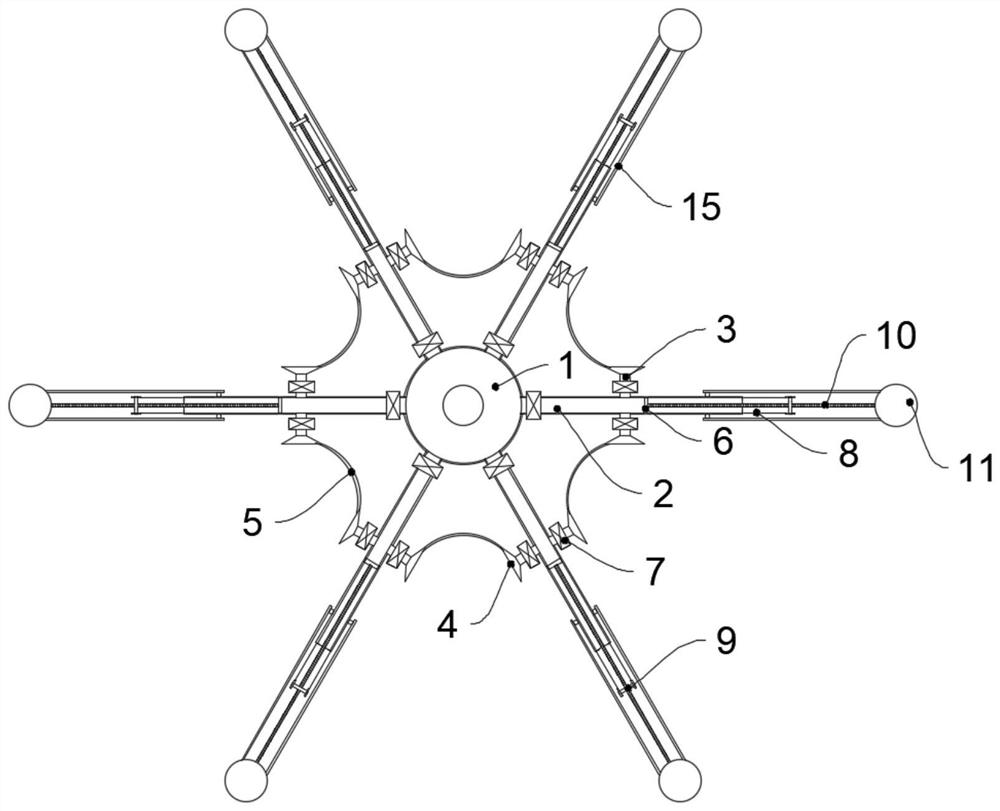

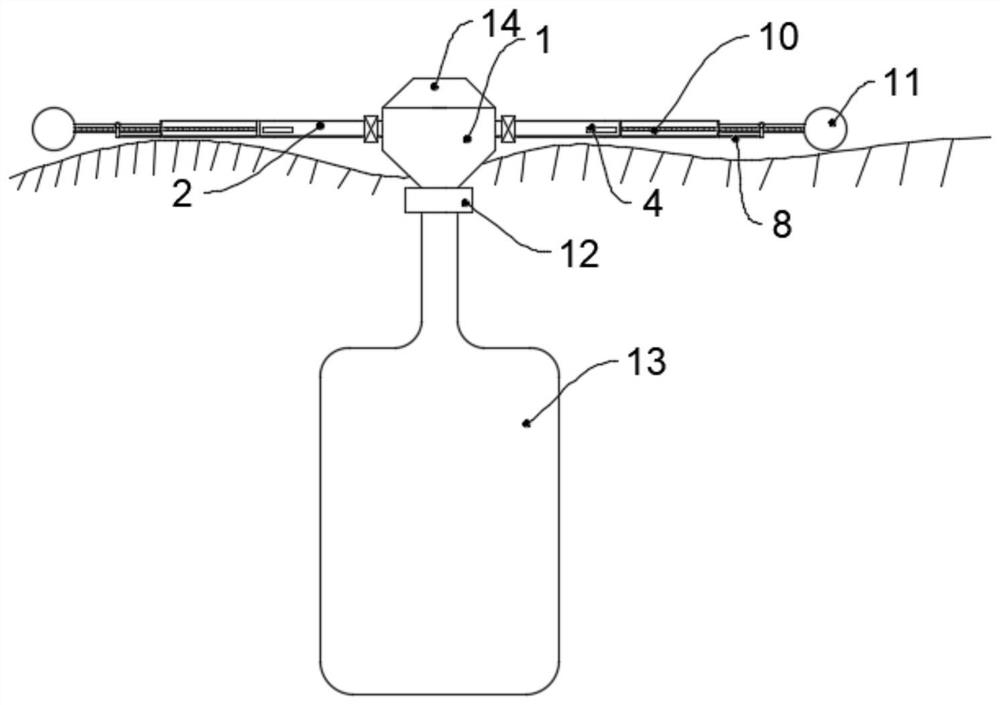

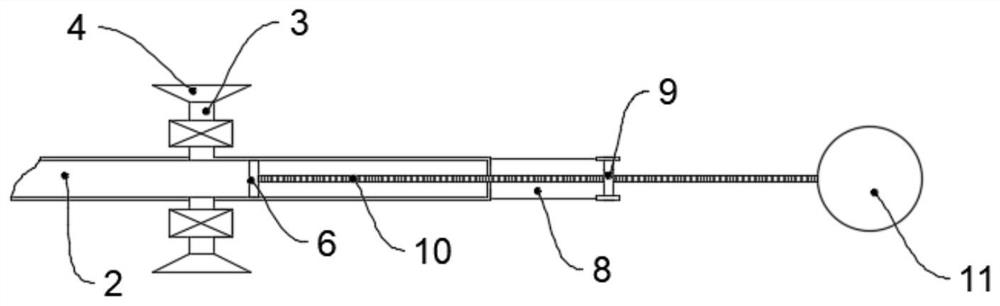

[0034] Such as Figure 1-3 As shown, a sea surface oil collection robot includes a collection bin 1, and a plurality of oil delivery pipes 2 are arranged on the side of the collection bin 1 in the circumferential direction. An oil inlet pipe 3 is provided on both sides of the oil inlet pipe 2. Leaked oil can enter the oil delivery pipe 2 through the oil inlet pipe 3. The inside of the oil delivery pipe 2 is provided with a piston block 6. The piston block 6 can move left and right in the oil delivery pipe 2. The piston block 6 is far away from the collection One side of the warehouse 1 is fixedly connected with a metal bellows 10. The metal bellows 10 is a metal link structure, which can be twisted and bent, but cannot be stretched. The movement of the metal bellows 10 drives the piston block 6 to move left and right in the oil delivery pipe 2, and then Positive or negative pressure is generated inside the oil delivery pipe 2 .

[0035] More preferably, one end of the oil del...

Embodiment 2

[0039] Such as Figure 4-5As shown, the difference between this embodiment and Embodiment 1 is that: the two sides of the oil delivery pipe 2 are provided with pin rods, and the pin rods are movably connected with a fixed frame 15, and the fixed frame 15 can rotate relative to the oil delivery pipe 2 through the pin rod, and the fixed frame The end of 15 is fixedly connected on the floating ball 11, and the fixed frame 15 rotates with the movement of the floating ball 11. The end of the fixed frame 15 away from the floating ball 11 is arranged on the left end of the steering shaft 9, and the floating ball 11 fluctuates up and down with the waves. , the fixed frame 15 rotates thereupon, because the rotating shaft of the fixed frame 15 is closer to the collection bin 1, when rotating, the distance that the floating ball 11 drives the metal bellows 10 to move will be improved under the action of the fixed frame 15 and the steering shaft 9 , thereby increasing the moving distance ...

Embodiment 3

[0041] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that: the inside of the collection bin loam cake 14 is provided with an alarm positioning module 18, and the alarm positioning module 18 can make the oil storage tank 13 send an alarm after collecting full leaking oil, reminding The staff replaced the oil storage tank 13, further improving the collection speed of the leaked oil. The bottom of the alarm positioning module 18 is provided with a contact switch, which can trigger the alarm positioning module 18 through the contact switch. The contact switch is arranged in the collection bin 1, and the collection bin 1 is threadedly connected with the oil filter 12, which is convenient for the staff to filter the oil. The filter 12 and the oil storage tank 13 are replaced and maintained. The inside of the collection bin 1 is provided with a push rod 16. One end of the push rod 16 passing through the oil filter 12 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com