Plate splicing welding machining device

A processing machine and welding torch technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of affecting the welding quality of welding wires, the single function of the device, and affecting the flatness of the board surface, etc., and achieve simple structure, optimization and beauty degree, to ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

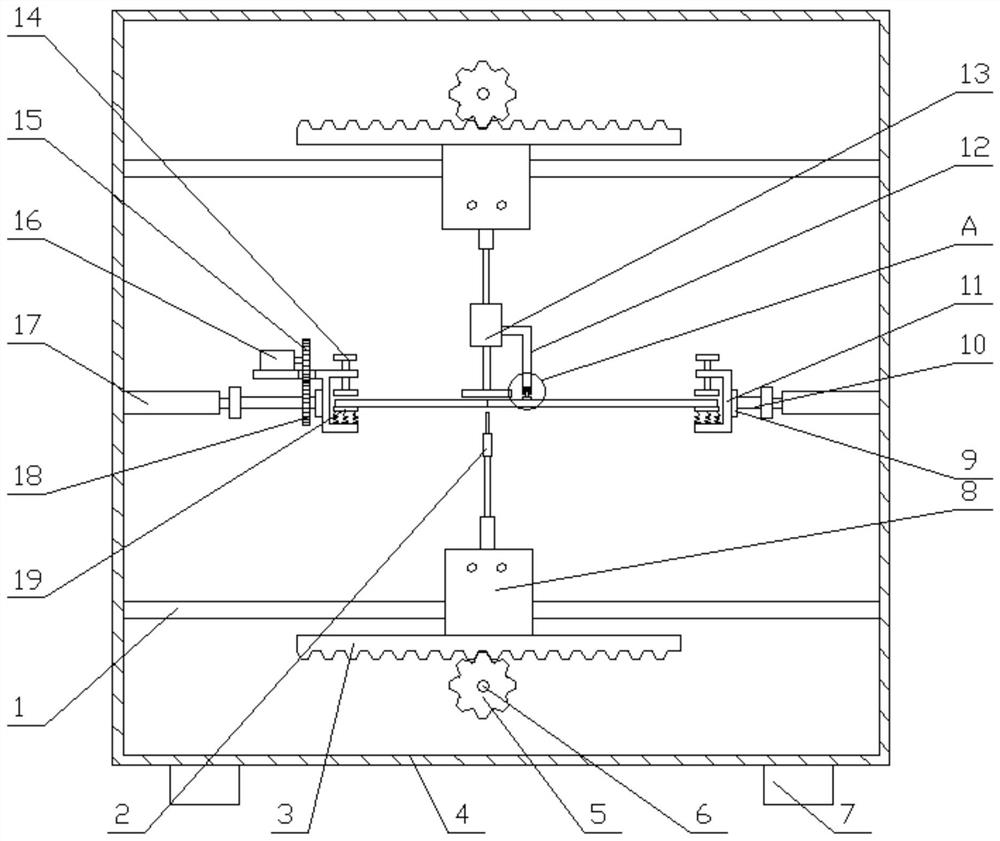

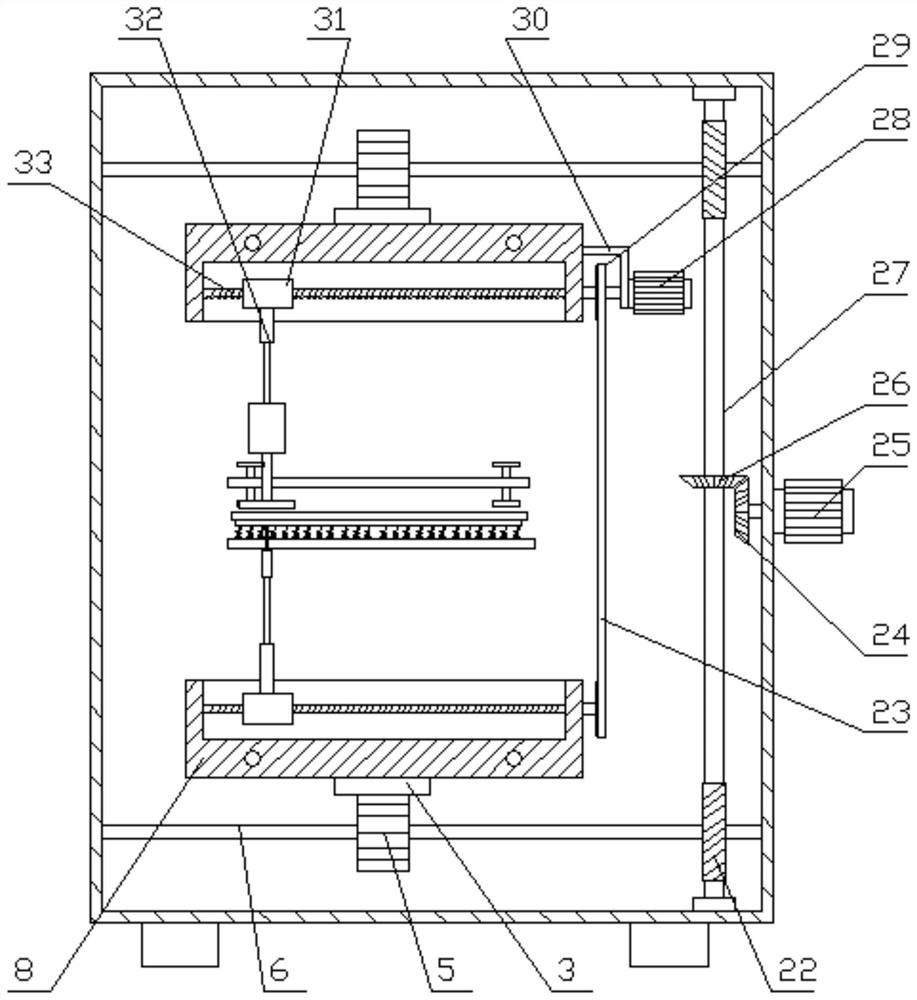

[0024] see Figure 1-2 and Figure 4 , a mechanical device for splicing and welding processing, comprising a first motor 16, a second motor 25, a third motor 28, a polisher 13, a welding torch 2, a first telescopic cylinder 17, a second telescopic cylinder 32 and a box body 4, The output end of the second motor 25 is fixedly connected to the first bevel gear 24, and the first bevel gear 24 is meshed with the second bevel gear 26. The lower side of the box body 4 is provided with several supports 7, and the supports 7 have a supporting effect. The upper and lower sides inside the body 4 are fixedly connected with a number of guide rods 1, and the guide rods 1 are slidingly connected with the tray 8. The guide rod 1 has a guiding effect on the movement of the tray 8, so that the movement of the tray 8 is more stable. 8. The outer side is fixedly connected to the rack 3, the rack 3 is engaged with the first gear 5, the first gear 5 is fixedly connected to the rotating rod 6, and...

Embodiment 2

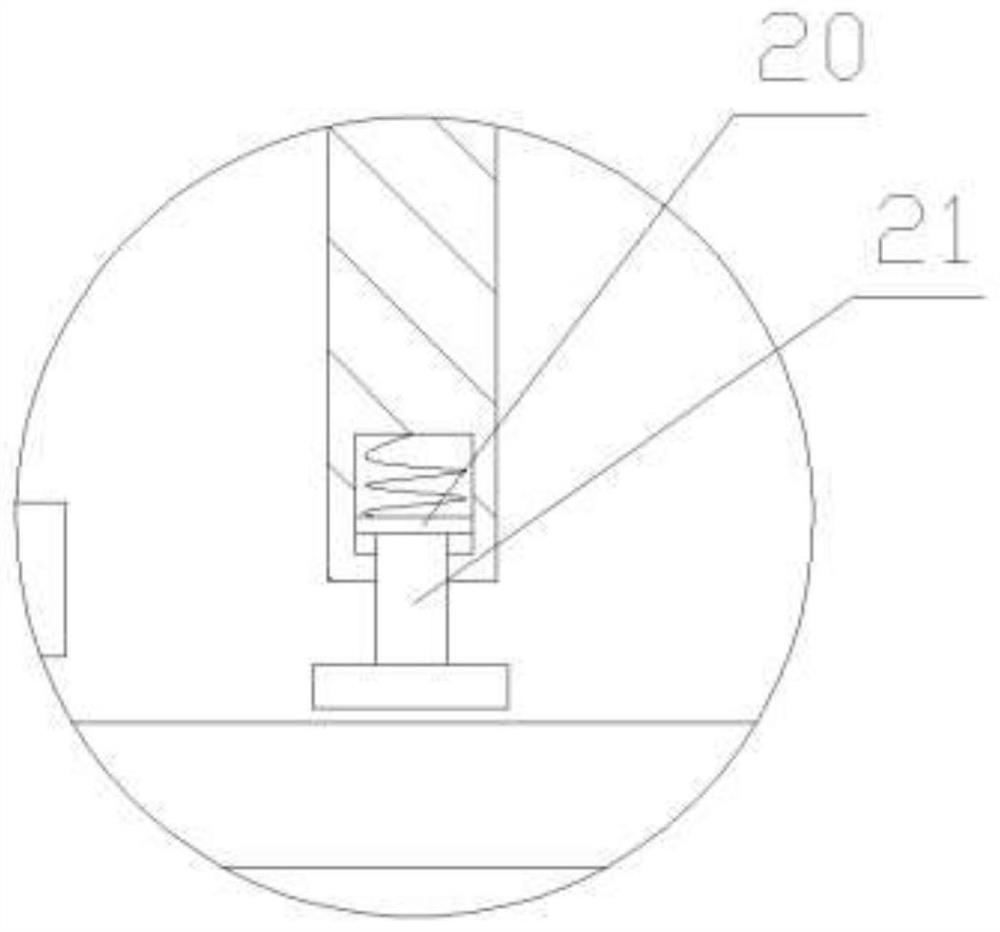

[0027] see image 3The difference between this implementation and the above-mentioned embodiment 1 is that a positioning rod 12 is arranged on one side of the polishing machine 13, and the lower end of the positioning rod 12 is embedded with a stopper 21, and the upper end of the stopper 21 is provided with a limit plate 20, and the limiter The plate 20 is slidably connected to the positioning rod 12, and the upper side of the limiting plate 20 is provided with a spring. The limiting plate 20 prevents the abutment 21 from disengaging, and the pressure of the abutting head 21 is buffered by the spring. , avoid welding torch 2, grinder 13 and jigsaw rigid collision.

[0028] The working principle of the present invention is as follows: when the above-mentioned plate welding processing mechanical device is used to weld the plate, firstly, the two plates to be welded are fixed on the left and right side supports respectively by the compression bolts 14. on the frame 11, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com