A liquid metal/polymer composite dielectric material and its preparation method

A liquid metal and dielectric material technology, applied in the field of composite materials, can solve problems such as difficulty in meeting performance requirements and degradation of material mechanical properties, achieve excellent flexibility and elasticity, improve mechanical properties, and facilitate processing and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of liquid metal / polymer composite dielectric material, concrete steps are as follows:

[0035] (1) Weigh 3g of acrylic acid in a small sample bottle at room temperature, then add 12g of deionized water, mix well and add 0.17g of gallium-indium alloy to it; wherein, the mass ratio of gallium-indium in gallium-indium alloy is 3:1g / g.

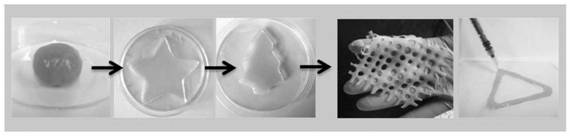

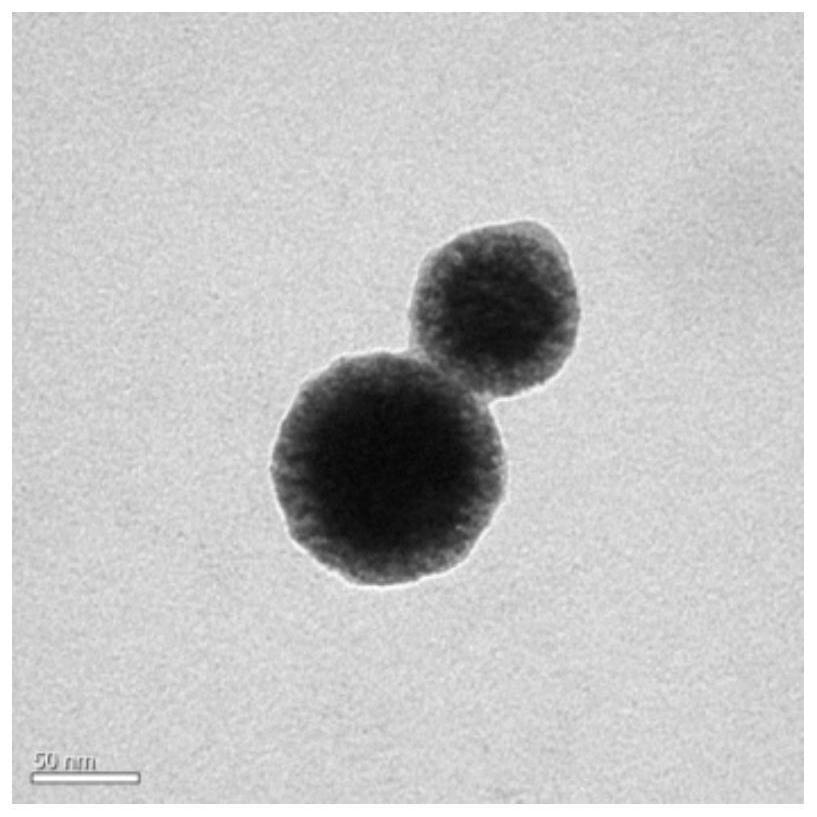

[0036] (2) The sample in step (1) is placed in a cell disruptor for ultrasonic dispersion, treated in an ice bath, and the ultrasonic time is 10 minutes, and the power is 300W (see figure 1 );

[0037] (3) The dispersion in step (2) was shaken on a shaker for 20 minutes, and then transferred to a plastic petri dish with a diameter of 6 mm, sealed and stored flat for 7 days to obtain a liquid metal / polymer composite dielectric material.

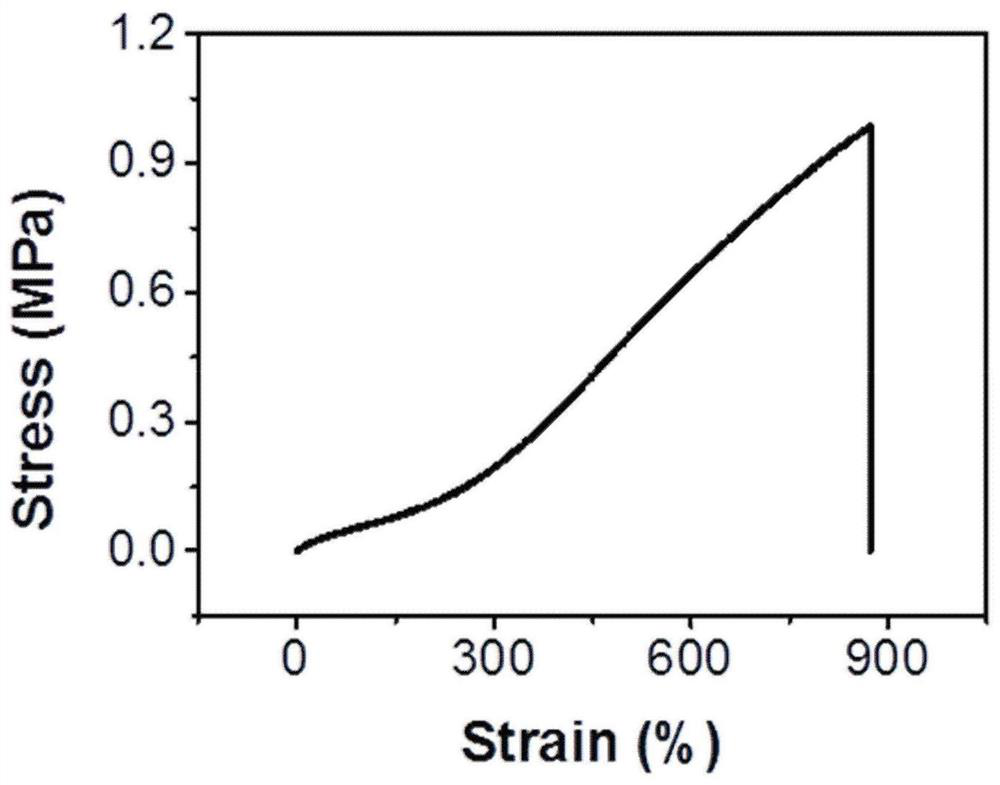

[0038] The material exhibits good plasticity during preparation (see figure 2 ) and then utilize E4980A Agilent instrument and 609B ferroelectric instrument to test the dielectri...

Embodiment 2

[0041] A preparation method of a liquid metal / polymer composite dielectric material, the specific steps are as follows:

[0042] (1) Weigh 4g of acrylic acid in a small sample bottle at room temperature, add 12g of deionized water, and add 0.2g of gallium metal to it after mixing;

[0043] (2) The sample in step (1) is placed in a cell disruptor for ultrasonic dispersion, treated in an ice bath, and the ultrasonic time is 15 minutes, and the power is 200W;

[0044] (3) The dispersion in step (2) was shaken on a shaker for 30 minutes, then transferred to a plastic petri dish with a diameter of 6 mm, sealed and stored flat for 14 days to obtain a liquid metal / polymer composite dielectric material.

[0045] Perform performance tests on the composite material obtained in the embodiment: the elongation at break of the liquid metal / polymer composite dielectric material is about 680%, and the toughness can reach 3.54MJ / m 3 The dielectric constant is 8.5 (25°C, 10kHz), and the prepar...

Embodiment 3

[0047] A liquid metal / polymer composite dielectric material, the specific steps are as follows:

[0048](1) Weigh 2.4g of acrylamide into a small sample bottle at room temperature, add deionized water to a total mass of 16g, add 52mg of N,N-methylenebisacrylamide after the acrylamide is fully dissolved, dissolve and mix Add 0.14g gallium-indium alloy to it after mixing; wherein, the mass ratio of gallium-indium in the gallium-indium alloy is 3:2;

[0049] (2) The sample in step (1) is placed in a cell disruptor for ultrasonic dispersion, treated in an ice bath, and the ultrasonic time is 20 minutes, and the power is 300W;

[0050] (3) The dispersion in step (2) was shaken on a shaker for 30 minutes, then transferred to a plastic petri dish with a diameter of 6 mm, sealed and stored flat for 7 days to obtain a liquid metal / polymer composite dielectric material.

[0051] Performance tests were performed on the composite material obtained in the embodiment: the elongation at bre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com